Hot-Dip Galvanized Steel Coil in Competitive Price and High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinccoating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

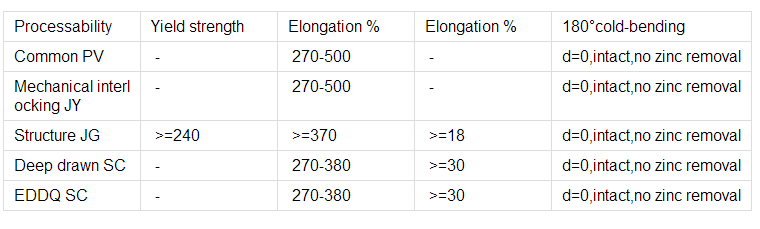

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of storage tanks?

- Steel coils are used in the manufacturing of storage tanks as they are rolled into cylindrical shapes and welded together to form the tank's body. The coils provide strength and durability to the structure, ensuring the tank can withstand the pressure and weight of stored materials.

- Q: What is the width range of steel coils?

- The width range of steel coils can vary depending on the specific requirements and industry standards, but generally, it can range from a few millimeters to several meters.

- Q: What are the common methods of painting steel coils?

- Painting steel coils can be done using various methods, depending on specific requirements and desired outcomes. Below are some commonly used techniques: 1. The most frequently employed method for painting steel coils is coil coating. It involves applying a layer of paint to the coil's surface before it is formed into its final shape. The coil is initially cleaned and treated with chemicals to ensure proper paint adhesion. Various techniques, such as roll coating, spray coating, or dip coating, are used to apply the paint. Finally, the coil is cured in an oven to ensure the paint dries and adheres correctly. 2. Electrostatic painting is another method where an electrostatic charge is used to apply paint to the steel coil. After cleaning and pre-treatment, an electrostatic charge is applied to the paint particles. These charged particles are attracted to the grounded coil, resulting in an even and efficient paint application. This method is commonly used for high-performance coatings due to its excellent coverage and adhesion. 3. For applications requiring a durable and long-lasting finish, powder coating is a popular method. Dry powder paint is electrostatically applied to the coil's surface. The powder adheres to the coil due to the electrostatic charge, and then the coil is heated in an oven to melt and cure the powder, creating a smooth and protective coating. 4. Spray painting is commonly used for smaller steel coils or touch-up applications. A spray gun is used to apply the paint in a controlled and even manner after the coil is cleaned and pre-treated. This method allows for precise control and customization of the paint application. The choice of painting method depends on factors such as desired finish, durability requirements, cost considerations, and the specific application of the steel coil. Each method has its own advantages and limitations, so it is crucial to select the most suitable one based on the project's specific needs and constraints.

- Q: I need a machine which can produce steel pipes, but I don't know where to look...If you want me to state dimensions etc. just say...Thanks :)

- I'll answer both those questions. Your first question is: Who can I buy a Steel Pipe Making Machine? To which I reply: anyone. I'd put great consideration on the age of the person you are giving this machine to, and perhaps their physical ability. Cripples don't work well with steel pipes. Unless you are...beating them with one. Second question is: Where can I buy a Steel Pipe Making Machine? My reply: OKorder, or Steel Pipe Makers Incorporated. You could probably just steal one out of their factories. They have billions, and the actual machines are no bigger than...a bus or two. Just pop one in your backpack on the way out. But honestly, I don't know where to get a steel pipe making machine. BUT! I do know where to get a steel pipe making machine making machine. Ask santa. (BTW: Why do you need the steel pipes? I smell conspiracy!)

- Q: What are the dimensions of a typical steel coil?

- The dimensions of a typical steel coil vary based on its intended use and manufacturer. However, a common range for the inner diameter is between 508 to 610 millimeters (20 to 24 inches), while the outer diameter can range from 1,200 to 2,000 millimeters (47 to 79 inches). The width of a steel coil can range from around 600 to 2,000 millimeters (24 to 79 inches), and the weight can vary from a few hundred kilograms to several metric tons.

- Q: What's the best material for color coated steel coil?

- Color steel roll is a kind of composite material, also called color coating steel plate. It is produced by continuous coating on the production line by surface degreasing and phosphating etc. after being coated with organic coating, the product is made by baking. Color steel roll is a composite material, both steel and organic materials, both of them a little. Both the mechanical strength of steel plate and easy molding performance, but also organic materials, good decoration, corrosion resistance.

- Q: Can steel coils be coated with weather-resistant materials?

- Yes, steel coils can be coated with weather-resistant materials such as zinc, aluminum, or organic coatings to enhance their resistance to corrosion and exposure to harsh weather conditions.

- Q: What are the common coil diameter and weight combinations available for steel coils?

- The common coil diameter and weight combinations available for steel coils vary depending on the specific requirements of the industry or application. However, some commonly available coil diameter ranges include 24 inches to 72 inches, while weight combinations can range from 3,000 pounds to 50,000 pounds or more. These dimensions can be further customized based on the needs of the customer and the capabilities of the steel manufacturer.

- Q: Project for school, we're learning about periodic elements and we have to choose an item from our hobbies to research what its made of. Any ideas on steel guitar strings??

- Steel is usually mainly made up of Iron (Fe) element, but it can also include Carbon (C) for a stronger steel or Nickel (Ni) for stainless steel.

- Q: what is the history of steel and how did they start making it, i need a link or an answer that is five paragraphs long. plus i need examples of subtitles about the history of steel. i am doing this for a science project and hope that someone can help me out.thanks

- There's wide history of steel, you can read different tutorials online to know more about it. Check wiki for detailed information.

Send your message to us

Hot-Dip Galvanized Steel Coil in Competitive Price and High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords