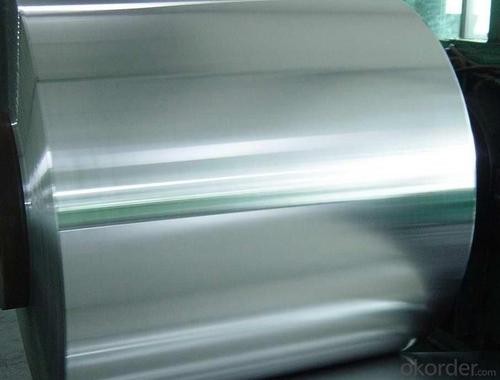

HOT-DIP ALUZINC STEEL COIL WITH NO.1 HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details | |||||

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,DX51D/DX52D/S250,280GD | Thickness: | 0.12-4.0 mm |

Place of Origin: | Brand Name: | N/M | Model Number: | ssp-226 | |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | galvanized/ Galvalume/zinc coatting |

Application: | strong anti-corrosion ability,cold bending molded manufacturablity | Special Use: | High-strength Steel Plate | Width: | 600-1250 mm |

Length: | in coil | product: | g40 prime/secordary hot-dip galvanized cold rolled steel coil/sheet | ||

Packaging & Delivery | |||||

Packaging Detail: | standard export package,Other types of packing can be customized as per client's requirement. | ||||

Delivery Detail: | as per client's requirements | ||||

Specifications

1.Mateials:SGCC,DX51D / DX52D / S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

8.Packaging Details:

Standard export package.

Other types of packing can be customized as per client's requirements.

- Q: What are the typical tolerances for steel coils?

- The typical tolerances for steel coils vary depending on the specific requirements and standards set by the industry. However, common tolerances for steel coils include thickness tolerances of +/- 0.001 to 0.005 inches, width tolerances of +/- 0.005 to 0.050 inches, and length tolerances of +/- 0.250 to 0.500 inches. These tolerances ensure that the steel coils meet the desired specifications and can be used effectively in various applications.

- Q: What is the average surface finish tolerance for steel coils?

- The average surface finish tolerance for steel coils can vary depending on the specific requirements and applications. However, commonly accepted standards for surface finish tolerance in the steel industry range between 10 to 20 microinches (0.25 to 0.5 micrometers).

- Q: How do steel coils contribute to sustainability efforts?

- There are several ways in which steel coils contribute to sustainability efforts. Firstly, steel is a material that can be recycled and reused multiple times without losing its quality or strength. This reduces the need for virgin steel production, which is a process that requires a lot of energy and has a negative impact on the environment. By incorporating recycled steel coils into manufacturing processes, companies can significantly reduce their carbon footprint and conserve natural resources. In addition, steel coils are known for their long lifespan and durability. This means that products made using steel coils, such as automotive parts, construction materials, or appliances, also tend to last longer. This reduces the need for frequent replacements, which in turn reduces waste generation and conserves resources. Moreover, advanced technologies can be used to manufacture steel coils in a more energy-efficient way, resulting in reduced greenhouse gas emissions. Steel manufacturers are increasingly adopting sustainable practices, such as using energy-efficient furnaces, optimizing production processes, and implementing recycling initiatives. These measures help minimize the environmental impact of steel production and contribute to overall sustainability efforts. Furthermore, steel coils are widely used in the construction industry, which plays a vital role in sustainable development. Steel is a crucial component in the construction of energy-efficient buildings and infrastructure, such as green buildings and renewable energy projects. These structures are designed to minimize energy consumption, reduce emissions, and promote resource efficiency. By using steel coils in these sustainable construction projects, the industry can contribute to a greener and more sustainable future. In conclusion, the recyclability, durability, energy-efficient manufacturing processes, and role in sustainable construction make steel coils a valuable contributor to sustainability efforts. By choosing steel coils and promoting their use, companies and industries can reduce their environmental impact, conserve resources, and contribute to building a more sustainable society.

- Q: - I'm considering doing my physics coursework on the uses of Mild Steel in skyscrapers and construction, would this be right? Some sources tell me mild steel is too weak, others say it is fine

- Mild steel doesn't really mean anything, technically. In today's world all steel is mild steel unless it's high carbon or alloy, which are mostly tool steels. You'll need to study steel much deeper than that to accomplish any real physics work relating to steel.

- Q: Can steel coils be coated with nickel?

- Yes, steel coils can be coated with nickel.

- Q: What are the different types of steel coil recoiling methods?

- There are several different types of steel coil recoiling methods, including oscillating recoiling, flying shear recoiling, and rotary recoiling.

- Q: What are the common coil diameters available for steel coils?

- The common coil diameters available for steel coils vary depending on the specific industry and application. However, some of the most common coil diameters for steel coils typically range from 24 inches to 72 inches. These diameters are often used in various sectors such as automotive, construction, and manufacturing. It is important to note that the specific coil diameter required may differ based on factors such as the size and weight of the material being coiled, the equipment being used to handle the coils, and the specific requirements of the end-use application.

- Q: Does anyone have any idea where I could get a necklace that has the British Steel by Judas Priest logo?

- Great album... British Steel, Um probably check Ebay... I'm not sure if any local stores would have it.

- Q: What are the trends and developments in the steel coil industry?

- Some of the current trends and developments in the steel coil industry include increased demand for high-strength and lightweight steel coils due to their use in various industries such as automotive and construction. Technological advancements have also led to the development of advanced coating methods, improving the durability and corrosion resistance of steel coils. Additionally, there is a growing focus on sustainability and environmental friendliness, leading to the use of recycled steel and the implementation of energy-efficient manufacturing processes in the industry.

- Q: How are steel coils used in the production of shipping containers?

- Steel coils are used in the production of shipping containers as they are formed and shaped into the required structure and size. The coils are unrolled and cut into sheets, which are then molded and welded to create the walls, roof, and floor of the container. This process ensures the container's strength, durability, and ability to withstand harsh shipping conditions.

Send your message to us

HOT-DIP ALUZINC STEEL COIL WITH NO.1 HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords