Hot Rolled Steel Strip Coils with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 66 m.t.

- Supply Capability:

- 222555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil,kitchen ware

3:Architectural purpose, Milk & Food processing facilities

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

Specifications of Steel Strip Coils:

Household Appliance | Refrigerator shutter &side panels, Rice Cooker, Washer, Microwave Ovens, Freezers, Air conditions, Water Heaters, Sterilization Cabinets, Range Hoods, Computer Panels , DVD/DVB panels, TV back panel etc. |

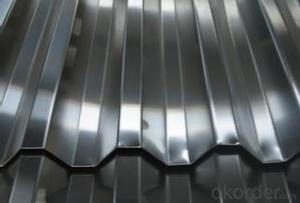

Construction Material | Fireproof Door &Kitchen Cabinet ,Ceiling, Sanitary Unit, Elevator etc. |

Transportation | Car, Ship, Trains, Aircraft Equipment. etc. |

Education and Health Field | Electronic Writing Boards, Projection Screens, Clean Operating Rooms, etc. |

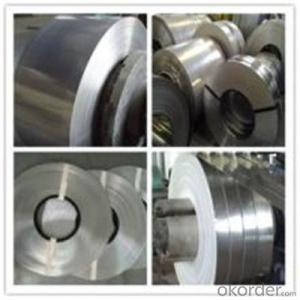

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: Can steel strips be used in the production of industrial machinery?

- Yes, steel strips can be used in the production of industrial machinery. Steel strips are commonly used as raw materials in various industries, including the manufacturing of industrial machinery. They are often formed, shaped, and welded to create different components such as frames, brackets, and supports, which are crucial for the construction and functionality of industrial machinery. The properties of steel, such as its strength, durability, and resistance to corrosion, make it an ideal material for use in the production of industrial machinery.

- Q: How do steel strips compare to other materials in terms of cost?

- Steel strips are typically more cost-effective compared to other materials due to their durability, versatility, and abundance.

- Q: What are the different surface laminating options for steel strips?

- There are several surface laminating options for steel strips, including hot-dip galvanizing, electroplating, powder coating, and painting.

- Q: Are steel strips suitable for automotive applications?

- Yes, steel strips are widely used and considered suitable for automotive applications due to their high strength, durability, and excellent formability. They provide crucial structural support and are commonly used in various parts such as body panels, chassis components, and suspension systems in automobiles. Additionally, steel strips offer cost-effectiveness and can be easily sourced and manufactured in large quantities, making them a preferred choice in the automotive industry.

- Q: Can steel strips be used in oil and gas applications?

- Yes, steel strips can be used in oil and gas applications. They are commonly utilized for various purposes such as manufacturing pipes, equipment, and structures in the oil and gas industry. Steel strips possess excellent strength, durability, and corrosion resistance, making them suitable for withstanding harsh environments and high-pressure conditions found in oil and gas operations.

- Q: Are steel strips suitable for making aircraft components?

- Yes, steel strips can be suitable for making certain aircraft components. Steel is known for its strength and durability, making it an ideal material for various applications in the aviation industry. Steel strips can be used to manufacture components such as brackets, fasteners, hinges, and reinforcement plates, among others. These components are crucial for ensuring the structural integrity and safety of an aircraft. Steel strips are often chosen for their high tensile strength, resistance to corrosion, and ability to withstand extreme temperatures and pressure. However, the suitability of steel strips for aircraft components depends on specific design requirements, weight limitations, and other factors. In some cases, alternative materials like aluminum or titanium may be preferred due to their lighter weight or better fatigue resistance. Overall, steel strips can be suitable for making aircraft components, but careful consideration of the specific application and engineering requirements is necessary to ensure the best material choice.

- Q: What are the main factors affecting the surface roughness of steel strips?

- The main factors affecting the surface roughness of steel strips include the quality of the steel material, the manufacturing process, the tooling used, the lubrication system, and the operating conditions such as speed and pressure.

- Q: How are steel strips used in the construction of industrial plants?

- Steel strips are commonly used in the construction of industrial plants for various purposes such as framing, support, and reinforcement. They are often utilized to create structural elements such as beams, columns, and trusses, providing stability and strength to the overall building structure. Additionally, steel strips can be used as cladding materials for walls and roofs, offering durability, weather resistance, and aesthetic appeal.

- Q: How are steel strips used in the production of stampings?

- Steel strips are commonly used in the production of stampings due to their strength, durability, and flexibility. These strips are typically made from various types of steel, such as carbon steel or stainless steel, and come in different thicknesses. In the production process, steel strips are fed into stamping machines, which are equipped with dies or molds. The strips are then shaped or formed into the desired shape or design by the stamping machine. This process can include bending, cutting, punching, or deep drawing, depending on the specific requirements of the stamping. The use of steel strips in stamping offers numerous advantages. Firstly, steel is a strong material, allowing for the production of robust and sturdy stampings that can withstand various forces or pressures. Additionally, steel strips can be easily manipulated and shaped to create intricate and precise stampings, making them suitable for a wide range of applications. Moreover, steel strips provide excellent resistance to corrosion, rust, and wear, making the resulting stampings highly durable and long-lasting. This is particularly important in industries such as automotive, aerospace, or construction, where stampings are subjected to harsh environmental conditions or heavy use. Lastly, steel strips are readily available and cost-effective compared to other materials, making them a popular choice for mass production of stampings. Manufacturers can efficiently produce large quantities of stampings using steel strips, contributing to cost savings and increased productivity. In conclusion, steel strips play a crucial role in the production of stampings. Their strength, durability, flexibility, and cost-effectiveness make them an ideal material for creating high-quality stampings used in various industries.

- Q: Are steel strips recyclable?

- Yes, steel strips are recyclable.

Send your message to us

Hot Rolled Steel Strip Coils with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 66 m.t.

- Supply Capability:

- 222555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords