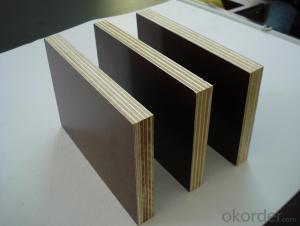

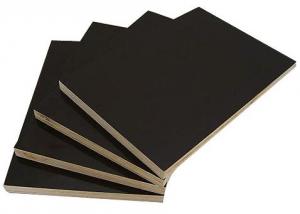

Home Depot 1/4 Plywood - Brown Film Faced Plywood Shuttering Plywood Phenolic Glue Construction Plywood 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Item name:Black/Brown Film Faced Plywood

Size:1220*2440/1250*2500

Core: poplar/hardwood/combi/birch

Glue: WBP, melamine, phenolic

Description:

Film Faced Plywood | ||

Size | 1220*2440mm,1250*2500mm,915*1830mm,1500*3000mm Or as clients’ requests | |

Film | Black(domestic) film, Dynea(import)brown film ,brown(domestic)film, black(domestic) film,red film, yellow film; | |

Thickness | 9mm,12mm,15mm,18mm,21mm etc; | |

Core | Poplar, Hardwood, Birch , Combi,Eucalyptus, etc; | |

Tolerance | Length/width :+/-0.2mm; Thickness: +/-0.5mm | |

Glue | MR(water proof), MELAMINE(water proof), WBP(phenolic); | |

Mositure content | 8%-12% | |

Modulus of rupture | >30MPa | |

Modulus of Elasticity | >6000MPa | |

packing | bottom is pallets, covered with plastic film,around is carton or plywood, strenghthen by steel or iron 3*6 | |

quantity | 20GP | 8pallets/22M3 |

40GP | 16pallets/42M3 | |

40HQ | 18pallets/55M3 | |

Usage | making construction formwork plywood, concrete formwork plywood,marine plywood etc | |

Payment | TT or L/C at sight | |

Delivery Time | Within 20 days receiving deposit or original L/C at sight | |

Features:

1. The face should be of high resistance to corrosion and moisture.

2. The face should be smooth and easy to take off from cement and easy to clean.

3. The core should be water resistant and won’t swell.

4. The core should be strong enough and won’t break.

5. The edge should be sealed and water proof.

Advantages of our film faced plywood

1. Above 18mm thickness film faced plywood , could be used 20 time at least

2. The inside each veneer is whole core

3. Each veneer is glued totally

4. Boiled for 10 hours , will not cracking

5. Twice hot press to strong joining capacity

6. Cold press again to strong joining capacity

7. 100% Dry

8. We have another glue making factory

FAQ

A. Quality :

With the skilled worker ,mature technology and ten years experience ,all our plywood are steady quality .

B. Price:

Due to the skilled worker ,mature technology and an experienced operating system , we can

quote you competitive price , so that you will have the price advantage to capture your market.

C.Service:

7*24hours , if any need, you can email or call us,we will do our best to meet your demand

D.Export experience:

Over ten years experience for exporting ,We are much familiar with

the export operation .

- Q: defects are divided into four grades

- , first class, second class, third, which, one, two, three for the general grade of the main plywood.

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other

- Q: Contemporary plywood market development

- as well as foreign high-quality hardwood wood constantly added for the Chinese plywood industry's continuous development To provide a wealth of raw materials; adequate human resources,

- Q: Multilayer board and plywood difference

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: What harm does the plywood factory work?

- occupational chronic benzene poisoning refers to the workers in the professional activities Long-term exposure to benzene vapor caused by hematopoietic system damage as the main manifestation of systemic disease.

- Q: The Preparation of plywood ingredients

- Loose loose side In the process of peeling or slicing, the side of the board and the knife contact side, this side due to reverse expansion and often produce a bottle peeling or cut fissure.

- Q: What are the defects in plywood material?

- holes In the process of shipment, holes are caused by hooks and tools for workers' picking.

- Q: The density of the plywood is greater than that of the same kind of wood

- The greater the unit pressure when gluing, the greater the density of the plywood. As the wood at high temperature easy to produce plastic deformation, hot glue gluing than the compression of the compression rate is greater.

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- . At that time, high-quality furniture, timber supply is sufficient, those who are not beautiful or poor durability of wood used only for non-exposed parts of furniture.

- Q: Does plywood contain formaldehyde?

- 12 cm plywood is usually 3-4 layers of natural wood chips "glue" together, each layer of double-sided roller plastic hot forming, the whole board about 3 kg of glue

Send your message to us

Home Depot 1/4 Plywood - Brown Film Faced Plywood Shuttering Plywood Phenolic Glue Construction Plywood 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords