Hollow Section Steel Pipe Construction Steel Section

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Hollow Section ASTM A500:

Hollow Section is to be used for . As the manufacturing process are perceived to be stronger and more reliable. Historically pipe was regarded as withstanding pressure better than other types, and was often more easily available than former pipe.

2、Main Features of Hollow Section ASTM A500:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Hollow Section ASTM A500: Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Hollow Section ASTM A500:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

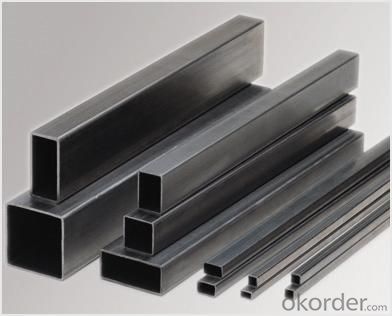

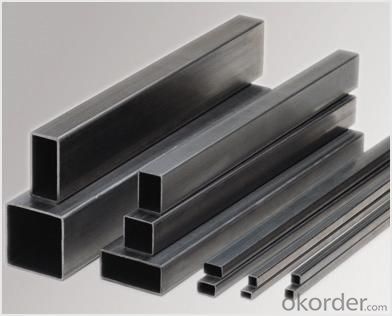

6、 Hollow Section ASTM A500: Images:

- Q: Can steel sheets be welded or joined together?

- Yes, steel sheets can be welded or joined together using various welding techniques such as arc welding, MIG welding, or TIG welding.

- Q: What are the different types of steel sheet alloys?

- There are various types of steel sheet alloys, including carbon steel, stainless steel, galvanized steel, and alloy steel.

- Q: Can the steel sheets be used for metal stamping?

- Yes, steel sheets can be used for metal stamping. Steel is a commonly used material for metal stamping processes due to its durability and strength. The steel sheets are typically cut into specific shapes and sizes, and then undergo a stamping process where a die and punch set are used to form the desired shape on the steel sheet. This process can be used to create various products such as automotive parts, household appliances, and industrial components.

- Q: What is the shelf life of steel sheets?

- The shelf life of steel sheets is indefinite, as they do not deteriorate or expire over time. However, proper storage and maintenance are necessary to prevent corrosion and ensure their long-term usability.

- Q: Can steel sheets be used in earthquake-resistant construction?

- Yes, steel sheets can be used in earthquake-resistant construction. Steel has excellent strength and ductility properties that allow it to withstand the forces generated during an earthquake. Additionally, steel sheets can be easily fabricated, assembled, and incorporated into various structural systems, making them a popular choice for earthquake-resistant construction.

- Q: Are the steel sheets corrosion-resistant?

- Yes, steel sheets can be corrosion-resistant depending on the type of steel used and the protective coating applied. Stainless steel sheets, for example, are known for their excellent corrosion resistance due to the presence of chromium that forms a passive protective layer on the surface. Additionally, galvanized steel sheets are coated with a layer of zinc, which acts as a sacrificial barrier to protect the underlying steel from corrosion. Other types of steel sheets can also be made corrosion-resistant through the application of coatings or treatments such as painting, powder coating, or plating. Therefore, it is important to consider the specific type of steel and any additional protective measures taken to determine the corrosion resistance of steel sheets.

- Q: Can the steel sheets be painted or coated?

- Indeed, it is possible to paint or coat steel sheets. Diverse industries often engage in the practice of painting or coating steel sheets to enhance visual appeal, guard against corrosion, and bolster durability. Prior to any application of paint or coating, it is crucial to thoroughly cleanse and prepare the steel surface to ensure proper adhesion. The choice of paint or coating depends on the desired finish, environmental conditions, and specific application. It is imperative to select a paint or coating that is compatible with the steel substrate and capable of enduring the intended use and exposure to chemicals, moisture, UV radiation, or other factors that may impact the performance and lifespan of the coating.

- Q: Can steel sheets be used for radiation shielding?

- Indeed, radiation shielding can be achieved with steel sheets. Due to its high density and capability to absorb and disperse radiation, steel is frequently employed as a radiation shielding material. The shield's thickness plays a pivotal role in safeguarding against radiation. Thicker steel sheets prove more efficacious in obstructing radiation due to their greater absorption potential. The application of steel sheets spans across diverse domains, including nuclear power plants, medical facilities, industrial radiography, and the construction of protective barriers in radiation-intensive regions.

- Q: What are the different alloying elements used in steel sheets?

- Some of the commonly used alloying elements in steel sheets include carbon, manganese, silicon, chromium, nickel, molybdenum, vanadium, and tungsten. These elements are added in varying quantities to enhance specific properties of the steel, such as strength, hardness, corrosion resistance, and heat resistance.

- Q: What is the average weight of a steel sheet per square meter?

- The average weight of a steel sheet per square meter can vary depending on the thickness and type of steel being used. However, a general estimate for mild steel sheets is around 7.85 kilograms per square meter. It is important to note that this weight can vary slightly based on the specific composition of the steel and any additional coatings or treatments applied to the sheet.

Send your message to us

Hollow Section Steel Pipe Construction Steel Section

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords