High Temperature Refractory Mortar Raw Materials

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Characteristic:

1.High modulus of rupture

2.Not easy to fall off

3.Short bonding time and less use

![]()

This product is produced by chemical reaction .Added more than two kinds of additives .The product has two kinds of shape:liquid and powder.The liquid product can be used directly .But the powder product should be add water and heat into paste.

![]()

| Item | JTHM-1450 | JTHM-1550 | JTHM-1700 |

| Classification temperature °C | 1450 | 1550 | 1700 |

| Bulk density g/cm3 | 1.7 | 1.9 | 2.0 |

Modulus of rupture Mpa (dried at 100°C) | 12 | 20 | 18 |

| Al2O3 % | 35 | 60 | 70 |

| Fe2O3 % | 1.3 | 1.2 | 0.9 |

| Quantity for KG/1000 bricks | 180 | 200 | 200 |

![]()

This product is widely used in ceramic fiber products,high-alumina insulation bricks,mullite insulation bricks,corundum insulation bricks and the products of not easy to bond when masonry .

Annual supply:

Our company has a dozen cooperative production factories which are better in productive technology and quality management. All the factories has passed ISO9001 quality management system certification. And the annual supply of dense shaped and unshaped refractory product is 100,000-200,000 tons.

Annual exports:

Now we have exported more than ten countries , such as Asia ,Europe and South America.

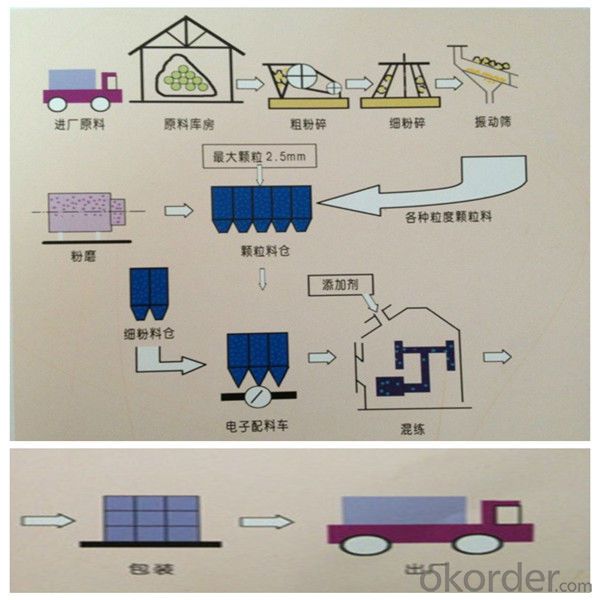

Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

Process flowdiagram:

FACTORY:

- Q: The primary problem, does the gas permeable brick is fired refractory bricks(refractory) ?

- Yes. After moulding by casting in the firing of 1450 ° degrees.

- Q: For refractory knowledge. What is the ratio of clay ramming?mass?

- Soil aggregates, dispersing agent, water reducing agent, plasticizer, binding agent and powder! ~ Bone meal feed approximately 6, OK

- Q: How long usually will the A-level fireproof materials prevent the flame?

- The classification of A-level materials is based on GB8624 - 2006 building materials and products combustion performance of grading method. Specific technical requirements are: 1, temperature ≤30 degrees; mass loss rate ≤50%; continuous burning time is 0; 2, the gross calorific value of main components, overall products, external non-substantial components ≤2.0MJ / kg; any internal non-substantial component ≤1.4MJ / kg;

- Q: What defect does fused cast refractories have ?

- What defect doesfusion-cast refractory material have ? In glass production, in addition to refractory as a building material and consider its durability, we still must attach great importance to its influence on glass quality. In such cases, the impact on the quality of glass is mainly the defects that eroded down refractory materials mixed in the glass, thus being prodeced of grass products. Defects are mainly foreign body defects such as sand, knot and wave reinforcement. What may directly affect the quality of glass are sidewall block and brick kiln bottom. I hope my answer can help you.

- Q: I would like to ask a friend that how much is the fire endurance of level A fireproofing glass?

- the fire endurance of fire window is: class A window is not less than 1.2 hours, class B window is not less than 0.9 hours, Class C window is not less than 0.6 hour. technical requirements: 1, materials and accessories (1) the window frame is made by a certain strength of steel frame or wooden frame which is sufficient to safeguard the integrity and stability. (2) steel frame and mound layer can select galvanized?steel?sheet or stainless steel plate. Its selection standards should be in line with the provisions of Article 5.1. in GB12955 "Steel Fireproof Door General Technical Condition" (3) the selection standards of wood frame and mound layer should be consistent with the provisions of Article 5.1.1. in GB14101 "General Technical Conditions of Wooden Fireproof Door" (4 ) the inner filling material of steel and wood frame should be non-combustible material. (5) fireproofing glass can choose the qualified products in fire resistance test and not affecting the fire windows. light transmittance of glass is not less than 75% of identical layers of ordinary plate glass. ( 6) a sealing material between the frame and the fireproofing glass should use the nonflammable material, it can play the role of fireproofing and smoke insulation in the fire disaster. I hope I can help you

- Q: Which one is better, fire-resistant wood or steel?

- Rebar would weaken and quickly collapse in the fire, and the fire resistance of a heavy log is much better than steel. In many ways, the fire resistance of a large log is equal to reinforced concrete. The heat transfer capacity of wood is 400 times smaller than steel, 8.5 times smaller than concrete. When burning, wood will form a layer of carbon in the surface, and as long as the cross-section of the timber is over a certain size, this layer of carbon it will become an excellent flame retardant layer to protect the interior of the wood from burning. So the United States and Japan and other European countries allow and encourage the use of wood structure with a large section (beam column of 8 inches or more) to construct public buildings without the need for fire treatment applied to wood surface. I hope my answer will be helpful to you.

- Q: What is the acceptance standard of refractory?

- Feeler gauge is used to check the thickness of the refractory brickwork joint. The top of the gauge can not be sharpened. Feeler gauge is of the width of 15mm, length of 100mm and thickness of 1, 1.5, 2 or 3mm. The thickness is eligible when the depth which the feeler gauge is inserted in is less than or equal to 20mm. Ten places should be inspected per 5m2 of masonry surfaces. It is qualified when the condition in which thickness of the brickwork joint is 50% larger than a predetermined depth is not less than five times and it is excellent when the condition is no more than two times.

- Q: What is refractory?

- Refractory materials are widely used in metallurgy, machinery manufacturing, chemical industry, petroleum, power and other industrial fields. It is an inorganic nonmetallic material mostly used in metallurgical industry with the minimum refractoriness of 1580 ℃, able to resist high temperature without softening (annealing). It accounts for 50% to 60% in total output. Refractoriness refers to refractory's ability to resist fire.

- Q: What are the refractories for converter?

- Analysis of refractories are as follows: MgO-C brick converter Dongxin refractory furnace cap, steel tapping hole, shaft, shaft, pool, air brick

Send your message to us

High Temperature Refractory Mortar Raw Materials

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords