High Temperature Insulation Glass Wool Aerogel Felts

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

Aerogel Insulation Felts

Using special nanotechnology, It combines a silica aerogel with reinforcing fibers to deliver very low thermal conductivity, low density and good flexibility in an environmentally safe product. It provides excellent properties of waterproof, sound absorption and shock absorption. It is an alternative to the common, environment unfriendly, inferior insulation products, such as PU, asbestos insulation felt, silicate fibers, etc.

2.Specifications

1.Superior Thermal Performance

2.Long service life

3.Environmentally Safe

4.Sound resistance

3. Advantages

(1).Superior Thermal Performance

The maximum use temperature is 1000℃,Its thermal conductivity is 1/3~1/5 of common insulators, helping reduce heat loss and optimizing space utility.

(2). Long service life

Unlike other traditional insulation materials, aerogel ’s three- dimensional, structure inhibits sintering warpage, and particles stack which may occur under hot temperature for long time. Therefore, aerogel insulation has long service life.

(3). Physically Robust:

It has flexibility and high tensile strength, resisting stretching and stress from linear contraction when temperature changes.

(4). Environmentally Safe:

Composed of inorganic materials, it contains no hazard. Stripping little chloridionm will cause no corrosion to the equipments and pipes.

Sound resistance and Shock Absorption

sound resistance and shock absorption help better the environment quality.

(5). Easy to Install

Extremely low density (200kg/m3) contributes to easy-to-cut and easy-to-install.

4. Technical Standard

Property | Unit | Techicial Standard | |

(refractoriness) | ---- | A Grade | |

(Density) | kg/m3 | <220< span=""> | |

(Lyophobic) | % | >99 | |

Thermal Conductivity | 25℃ | W/(m·K) | ≤0.023 |

70℃ | ≤0.029 | ||

200℃ | ≤0.036 | ||

300℃ | ≤0.045 | ||

400℃ | ≤0.056 | ||

5. Application

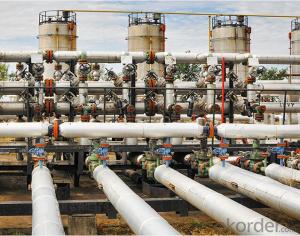

Oil pipe, steam pipe, refrigerator interlining, oil tank, central airconditioning pipe, chemical pipe with the requirement of fire resistance, vehicle thermal insulation, national defence, military industry, heat supply pipelines in city insulation, biological medicine pipes and equipment and so on.

- Q: What is the density of high-temperature glass fiber

- glass wool density is generally between 16K ~ 32K, mainly used for acoustic and thermal insulation, but easily casues layering. Harmful substances comes out at the first heating. it is cheap. The density of the glass fiber acupuncture felt is 110~180kg/m3. It is mainly used for environmental protection, sound-absorbing. it has better fireproof property but it is more expensive.

- Q: Are fireproof glass wool and centrifugal glass wool the same?

- Although both of which are glass wool, there are main three types of products involved. Centifugal glass wool includes hydrophobic glass wool and ordinary glass wool. Centrifugal glass wool is produced from centrifugal injection. The centrifugal glass wool you said is only a general name, and it also belongs to centrifugal glass wool material.

- Q: How to increase soundproof performance of houses(with glass wool)?

- sound absorption and insulation, silencer sponge and foam.

- Q: Whether the rock wool is belong to the glass wool product or not.

- the manmade inorganic fiber is made by the high-speed centrifugation equipment. it molding is good. the different rock wool thermal insulation products has different requirements, and it can be made into different specification and the material of the cotton-shaped is the inorganic substance fiber with stable chemical performance. Glass wool is melten glass fibrosis, it is corrosion resistance, and man-made inorganic fiber, while adding a special binder and dust?laying?oil, low bulk density, good sound absorption, thermal insulation, low thermal conductivity. Glass wool belongs to a category in glass fiber, chemical composition belongs to glass, melting in high temperature! the specific defination is in the following rock wool is taken the natural basalt as the main raw material. the two names are different but the thermal insulating and refractory material performance is nearly the same.

- Q: Which one has better noise absorption performance, the mineral wool or the glass wool?

- Glass wool has better sound-absorbing effect, and its density is smaller, and it has smaller sound reflectivity.

- Q: Who knows the construction scheme of external wall thermal insulation glass wool ?

- Glass wool external wall insulation construction shceme: in this project, 50 thick glass wool thermal insulation boards are used, which has became popular in Beijing as external wall thermal insulation material only in recent two years so there are no mature check, acceptance and construction specifications. It is constructed according to the design negotiations, the reference standard, Atlas 10BJ2-11, JGJ144-2004, GB50411-2007. Construction of glass wool is difficult. Therefore, construction scheme should be made according to specification and design requirments and negotiation records before construction. At the same time, we should strengthen control during construction and solve problem immediately and construct in strict accordance with Atlas and technical schedule. The insulation construction period of this project is 20 days. It is very tight so we need to make proper arrangement to ensure insulation construction period. Dingfuzhuang Middle School insulation construction: first teachingl buildings, then laboratory buildings, finally canteen. When the outer scaffolds are all constructed in the teaching building, carry out construction in four facades of the teaching building from bottom to up. When the laboratory building outer is sprayed with concrete, carry out laboratory building outer thermal insulation construction. At this time, more workers are needed to ensure insulation constructions of two buildings carried out simultaneously as the teaching building insulation constructio is not finished. When the insulation project is constructed in canteen outer, add more workers to ensure insulation constructions of the three buildings carried out simultaneously.

- Q: What advantages do thermal insulation glass fiber wool have?

- Thermal insulation glass fiber wool, whose raw materials are glass ball or waste glass, is made by many processes like high temperature melting, wire drawing, winding, weaving, etc. It is an inorganic non-metallic material with excellent performances. There is a wide range of the material. The following are the advantages of it: 1, It has superior heat insulation capability. According to physical principles, excellent heat insulation materials with small heat conduction rate of gas have many air-cavities inside. 2, It is noncombustible without inflammability, deformation and embrittlement, able to resist high temperature up to 700 degrees. It is tested that its combustion performance can reach at A1-level. 3, it does not contain any adhesive, being an non-toxic environmental friendly material without any smell. Compared with traditional glass wool and rock wool products, it does not contain any adhesive, and it will not produce any toxic and acrid smoke at high temperatures. 4, It has high insulativity. Glass fiber is the best insulation material. 5, Glass fiber is insusceptible to strong acid with superior corrosion resistance. It will not lose its functions and characteristics for a long time. 6, It is good in recovery performance. Glass fiber contains numerous fixed air-cativities, which gives it superb restorability. It is insupsceptible to any shock and vibration with a tensile strength of over 1.0kg. 3, It has good insulation, strong heat resistance, great corrosion resistance and high mechanical strength, but it has the disadvantages — brittleness and poor abrasive resistance. Wish it will help you.

- Q: What is the fire rating of fireproof sound-insulating glass wool board?

- Glass cotton can be made into board materials after the curing process, and can retain its insulation and sound absorbing properties at random temperatures.glass wool board is also known as sound insulation board/cotton, sound absorbing board, fireproof cotton, fillinf cotton for sandwich wall.it is high-quality insulation and fireproof materials for absorbing sound and reducing noise in architectural and industrial fields. It is also used for meeting room, audio-visual room, studio, auditorium, piano room, rehearsal rooms, gymnasium, computer rooms, theaters, television stations, radio stations, laboratories, studios, laboratories, recording studios, sound-absorbing in places like bars and KTV. 1. environmentally friendly, non-toxic 2. light and simple construction 3. strong shock resistance, long durability 4. strong insulation and low thermal conductivity 5.A level non-combustible material,strong fireproof property 6. It can absorb sound and reduce the noise.

- Q: What is the difference between Kun Nai glass?wool?board and rock wool?

- Hastelloy alloy has made remarkable breakthrough in 1960s. Before that corrosion hinders the development need to weld the alloy solution treatment HAZ corrosion resistance can lower the number of devices produced by welding must be applied engineering problems to provide solutions HastelloyC-276 case http://www.jyx66 /

- Q: Is centrifugal glass wool or rubber and plastic insualtion board better for air-conditioning air duct insualtion?

- Rubber and plastic insulation board is better.

Send your message to us

High Temperature Insulation Glass Wool Aerogel Felts

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords