Superior Thermal Performance Glass Wool Insulation Aerogel Felts

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description

Aerogel Insulation Felts

Using special nanotechnology, It combines a silica aerogel with reinforcing fibers to deliver very low thermal conductivity, low density and good flexibility in an environmentally safe product. It provides excellent properties of waterproof, sound absorption and shock absorption. It is an alternative to the common, environment unfriendly, inferior insulation products, such as PU, asbestos insulation felt, silicate fibers, etc.

2.Specifications

1.Superior Thermal Performance

2.Long service life

3.Environmentally Safe

4.Sound resistance

3. Advantages

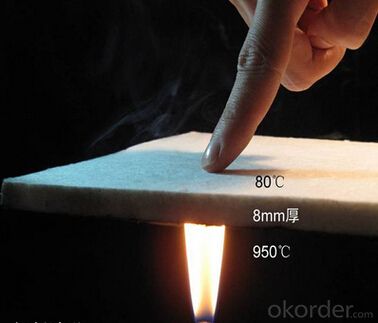

(1).Superior Thermal Performance

The maximum use temperature is 1000℃,Its thermal conductivity is 1/3~1/5 of common insulators, helping reduce heat loss and optimizing space utility.

(2). Long service life

Unlike other traditional insulation materials, aerogel ’s three- dimensional, structure inhibits sintering warpage, and particles stack which may occur under hot temperature for long time. Therefore, aerogel insulation has long service life.

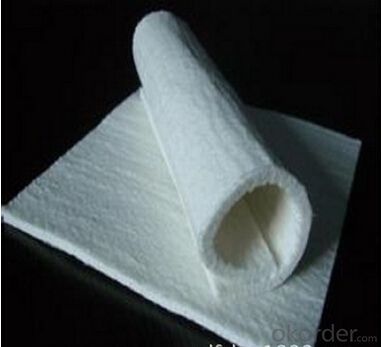

(3). Physically Robust:

It has flexibility and high tensile strength, resisting stretching and stress from linear contraction when temperature changes.

(4). Environmentally Safe:

Composed of inorganic materials, it contains no hazard. Stripping little chloridionm will cause no corrosion to the equipments and pipes.

Sound resistance and Shock Absorption

sound resistance and shock absorption help better the environment quality.

(5). Easy to Install

Extremely low density (200kg/m3) contributes to easy-to-cut and easy-to-install.

4. Technical Standard

Property | Unit | Techicial Standard | |

(refractoriness) | ---- | A Grade | |

(Density) | kg/m3 | <220< span=""> | |

(Lyophobic) | % | >99 | |

Thermal Conductivity | 25℃ | W/(m·K) | ≤0.023 |

70℃ | ≤0.029 | ||

200℃ | ≤0.036 | ||

300℃ | ≤0.045 | ||

400℃ | ≤0.056 | ||

5. Application

Oil pipe, steam pipe, refrigerator interlining, oil tank, central airconditioning pipe, chemical pipe with the requirement of fire resistance, vehicle thermal insulation, national defence, military industry, heat supply pipelines in city insulation, biological medicine pipes and equipment and so on.

- Q: what's the price of high temperature resistance glass wool?

- Hello the different thickness and unit weight of the glass wool has different prices , generally a few dollars for each square meter, then if you are from Hebei, there are many companies have this products in Langfang, you can go there to consult. Price depends on how much K you need, that is, the number of density, the current mill price is around 2500 for one ton.

- Q: What are the advantages and disadvantages of centrifugal glass wool?

- Centrifugal glass wool board is fiber product, so human body will be allergic, whose temperature endurance is 400 degrees with good thermal insulation effect, mainly used in buildings and underground pipes. They are thermal insulation construction products approved by fire control department .

- Q: Now what is the latest color steel sandwich board? such as: Foam, stretches, glass wool

- it is better to use rock wool because it is fireproofing and sound insulation.

- Q: To reach better sound absorption effect, which should be filled in the keel, glass wool felt / board or polyester fiber cotton felt / board ?

- Both materials are inappropriate to used for noise insulation, for glass wool and polyester fiber cotton are sound-absorbing materials. Neither is good for sound insulation. They can be used to prevent echo formation in the room, and their function is to reduce the reflection of sound indoors.

- Q: Which one has better noise absorption performance, the mineral wool or the glass wool?

- And make it applied to spaces meet the requirements (for example conference rooms require clear voice). Glass wool only absorbs sound over 1500HZ. For example, in order to let the sound field to achieve more pleasant effect, sound-absorbing wool (mineral wool, to remove the noises of people in the waiting room (which is intermediate frequency). Professional sound-absorbing boards can absorb the chosen sound according to which part of sound you need. Curtains are ordinary sound-absorbing matter and absorb only 30%. Performance halls require the sound to reverberate enough but it should not be too long while KTV require the sound appealing.

- Q: The main classification and difference of glass wool

- The main classification and difference of glass wool

- Q: what is the raw materials producing glass wool insulation materials?

- simply put. It is a kind of glass, just like using white sugar to make cotton candy.

- Q: During the construction of steel structure, should the aluminum foil of glass wool be directed indoors or outdoors? Why?

- The aluminum foil of glass wool should point toward the indoor.

- Q: What are the construction methods of glass?wool?board used in external wall?

- The phenomenon of moisture condensation in glass wool should be prevented.moisture condensation in glass wool, a layer of vapour barrier should be attached to the surface of the glass wool.A layer of glass wool should be fixed on the wall by insulation supporting pin prevent the glass wool from falling and thermal insulation properties from reducing.

- Q: What's the centrifugal glass wool?

- It is sound absorbing cotton, I hope this answer can help you. . .

Send your message to us

Superior Thermal Performance Glass Wool Insulation Aerogel Felts

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords