High Temperature Heating Insulation Basalt Tapes

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

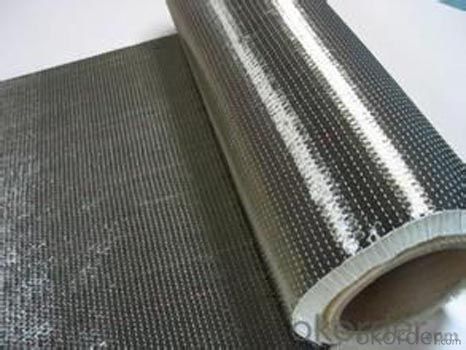

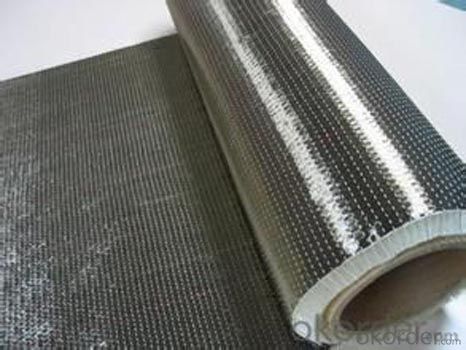

Basalt fiber unidirectional fabric was woven basalt fiber by high-performance engineering materials, a tensile strength ≥ 2100Mpa, elastic modulus ≥ 105Gpa, elongation ≥ 2.6%. Basalt fiber production according to the follow-up required on a single uniform coated wire sizing, and sizing of various resins and Canada are matched with a coupling agent, give full play to basalt fiber unidirectional fabric enhancement. Basalt fiber unidirectional Bouilhou the way for replacement of carbon fiber reinforcement fabrics used in the construction and repair of bridges. Reinforcement in the construction field for the column of basalt fiber unidirectional fabric is very close to the seismic performance of reinforced carbon fiber unidirectional cloth.

Applications

Building bridges of consolidation, reinforcement and repair; radar cover, shipped machine parts, radar antenna; tanks armored body, structure, wheel hub, torque rods and bushings; sports skis, alpine skis, surfboard, etc.. Basalt fiber unidirectional fabric of basalt fiber products is currently the most mature product.

1.Cover board, manhole and handhold sealing materials in high temperature, high pressure stove tank, caldron, etc.

2.High temperature resistant thread, rope and belt

3.Corrosion and friction resistant rope and packing set

4.Bundling electric motor coils an deep well hoisting rope slings

5.High temperature resistant sewing threads

Performance

Basalt fiber unidirectional fabric of the technical indicators

Areal density (g/m2) | Single fiber diameter (μm) | Tensile strength (Mpa) | Elastic modulus (Gpa) | Elongation rate (%) | Thickness (mm) |

260 | 13 | 2100 | 105 | 2.6 | 0.100 |

300 | 13 | 2100 | 105 | 2.6 | 0.115 |

360 | 13 | 2100 | 105 | 2.6 | 0.138 |

380 | 13 | 2100 | 105 | 2.6 | 0.146 |

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2. Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: What are the main molding processing methods of plastics

- There are many methods of plastic forming. Six main forming methods are listed below: 1 injection molding and injection molding, extrusion molding. 2. extrusion molding, which is the main molding of thermoplastic plastic molding, 3 hollow blow molding, also known as the 4 compression molding also called compression molding. The upper and lower mold installation the template in the press on, the plastic material directly into the cavity, the mold is closed, full of plastic cavity in the heat and pressure, setting after plastic products. 5, injection molding and transfer molding. One of the main forming method is thermosetting plastics. It is feeding room, plastic pellets into mould in the heating, melting plastic under pressure through the pouring system of bottom mold transfer chamber fills the cavity, and then cure it. 6, solid molding molding plastics in melting temperature, in the molding process No obvious flow condition, for two times molding plastic sheet, such as vacuum molding, compression molding and air pressure molding, original for thin-walled parts molding, first used in the manufacture of thick wall parts. 7, other molding calendering, there are many casting plastic molding methods...

- Q: What is the technological process of glass?Fiber?chopped?strand mat?

- Fiber reinforced epoxy resin composite material forming process. Compared with traditional materials, the composite material has a series of irreplaceable characteristics, which has been developed rapidly since the second world war. Although the production is small, but the level of composite materials is one of signs that marks national or regional science, technology and economic level. Composite material is mainly composed of two parts: reinforced material and base material. Reinforced material: In composite material, some reinforced material such as the glass fiber in glass?reinforced?plastics and carbon fiber in CFRP(carbon fiber reinforced material) give major mechanical property to composite material. Matrix: Matrix is a single material which aims to make composite material as a whole such as resin in glass?reinforced?plastics( epoxy resin referred in this paper). Composite materialcan be divided into three kinds according to the matrix material: resin composite material, metal matrix composite material, and inorganic nonmetallic composite material such as ceramic matrix composite material.

- Q: What type of cement is used in the common GRC component?

- Of course, the low alkali rapid hardening sulphoaluminate cement is good, but we do not use it as the cost increased, and the additive is double glass fiber mesh cloth. Cememt ans sand shall be simple packed. If it is the large mount, we could use machine for production

- Q: Carbon fiber is better than glass fiber reinforced plastic

- Carbon fiber is better than glass fiber reinforced plastics, lighter in weight, stronger in strength and stronger in toughness. Compared with the traditional carbon fiber glass fiber, the young's modulus is more than 3 times; compared with Kevlar fiber, the young's modulus is about 2 times in the organic solvent, acid and alkali insoluble swelling, outstanding corrosion resistance.

- Q: Glass fiber thermal insulation belt for glass fiber.

- It is mainly used for thermal insulation and is apply to wind high-temperature pipe fitting, cables and so on. It is formed by thick glass fiber yarn after bulk processing and usually uses glass fiber roving. It is widely used for electric heating wire and heating element.

- Q: What can be produced by waste flat glass.

- No, it can't.

- Q: What is the material of glass steel? How to make it?

- We mainly use glass fiber, and the adhesive is composed of unsaturated resin; curing agent, cyclohexanone; peroxide initiator, cobalt naphthenate (also used for the curing agent of benzoyl peroxide, initiator amine). The rate of solidation changes sharply with temperature, humidity and the curing to recipe. Roughly 100: 4: 1. There are processing winding machine to wind liner (tank shape) in axial and circumferential direction, soak it with adhesives before winding. According to the different liner, it is divided into two categories: Glass steel liner glass cloth paste and polyethylene liner polyethylene rotational molding.

- Q: How to deal with the folding force of glass fiber plastic coated yarn.

- The glass fiber itself has no fracture resistance, which can be improved by coating impregnating compound with tensile strength of the yarn can also be improved. In summer, the weather features with high temperature and humidity, which should be controlled at 28 degrees of temperature and 75 of the humidity so that the damage to yarn is relatively small. You may consider to improve the toughness of the coating material.

- Q: What is grc material?

- Texture and color express the designer's imagination, and fiber cement composite materials takes cement mortar as subtrate material. [Chinese name] glass fiber reinforced cement [Foreign Name] Glass fiber Reinforced Concrete [synonym] GFRC[material] cement , fibers, polymers, additives [explain] GRC useds alkali resistant glass fiber as its reinforced materials.

Send your message to us

High Temperature Heating Insulation Basalt Tapes

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords