High Strength Polypropylene Structural Geotextile Non Woven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Products Description:

Geotextile fabrics

Material:polyester fibre

Width:2-6m

Colour:white or black

Use:road ,highway,filter

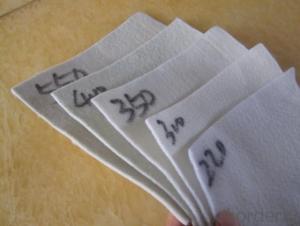

Weight:100-1000g/m2

Tensile strength:2.5KN/m-25KN/m

Break elogation:25-100%

2. Products Feature:

1. Weed suppressant and drainage control landscaping fabric

2. Spun bonded non-woven fabric – will not fray when cut

3. Easy to use

4. Environmentally friendly

5. Allows water, air and nutrients through, suppressing weeds without the use of chemicals

6. Good alternative to Plantex® where cost is a factor

7. UV Stabilised

8. Reduces the level of watering required due to the slower rate of water evaporation

3. Products Function:

1. Cover crops in the ground surface,prevent weeds and against the insect

2. Controlling soil humidity and the temperature

3. Does not affect the growth of the crops

4. Protects plants from harmfully solar radiation

5. Air permeability, water permeability help crops growth.

6. Mothproof, eco-friendly, breathable, anti-bacteria, tear-resistant, fusible

4. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: 400g / m2 two cloth a layer of water permeable geotextile technical requirements

- Two cloth a film will not be permeable, the composite film index breaking strength 5kn top broken 1.1kn tear 0.15kn peel 6n / cm or substrate fracture without stripping, the current 2008 standard weight has not been required, the original standard For not less than 360 grams

- Q: Geotextile packaging what are the requirements

- Geotextile packaging requirements are as follows: 1, staple acupuncture non-woven geotextile according to set into a long volume of packaging. The fixed length shall be determined in accordance with the product specification or the parties concerned. 2, the product of the splicing rate should be less than 15%, the total length of each piece of stitching products should be 7.1.1 fixed length plus 1m or more, every 100m to allow splicing 2, or by the supply and demand sides to determine. 3, the length of the product in the 30m below a small package can be a separate package, for a head treatment, 4, product packaging should ensure that no scattered, no damage, no pollution. Users have special requirements, the supply and demand sides to determine the consultation.

- Q: What are the advantages of using geotextiles in road construction?

- There are several advantages of using geotextiles in road construction. Firstly, geotextiles act as a barrier between the subgrade and the base material, preventing the mixing of the two layers. This helps in maintaining the stability and quality of the road. Secondly, geotextiles help in distributing the load more evenly across the road surface, reducing the stress on the underlying layers and increasing the lifespan of the road. Additionally, geotextiles can improve the drainage system by allowing water to flow through them, preventing the accumulation of water and reducing the chances of road damage due to moisture. Lastly, geotextiles are cost-effective and easy to install, saving both time and money in road construction projects. Overall, the use of geotextiles in road construction enhances the durability, strength, and performance of the road, making it a beneficial choice for infrastructure development.

- Q: Application of composite geotextile

- Water conservancy projects: seawall, river embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control and rescue. Highway and railway engineering: soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. Electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project.

- Q: What are the factors to consider when specifying geotextiles?

- When specifying geotextiles, it is important to consider factors such as the type and purpose of the project, the desired functions of the geotextiles (filtration, separation, reinforcement, etc.), the site conditions, the expected loads and stresses, the required durability and longevity, the installation and maintenance requirements, and the cost-effectiveness of different geotextile options.

- Q: How do geotextiles contribute to the performance of geocell systems?

- Geotextiles play a crucial role in enhancing the performance of geocell systems by providing reinforcement, separation, and filtration functions. They help distribute and transfer loads evenly across the geocell structure, enhancing its stability and load-bearing capacity. Geotextiles also prevent the mixing of different soil layers, ensuring proper confinement within the geocells. Additionally, they act as a filter, allowing water to drain while preventing the migration of fine particles that could clog the system. Overall, geotextiles significantly contribute to the overall performance and longevity of geocell systems.

- Q: Tunnel longitudinal drainage pipe with geotextile wrapped after the need for waterproof board wrapped, why can not be wrapped with a waterproof board

- You should say that the drainage pipe should be seepage of plastic blind tube it. Geotextile wrapped in the role is to play a filtering effect, filter the water to drain the sediment. Chong Hong geotextile material manufacturers

- Q: Can geotextiles be used in shoreline protection projects?

- Yes, geotextiles can be used in shoreline protection projects. Geotextiles are often used to stabilize and reinforce soil in coastal areas. They can help prevent erosion, improve drainage, and provide a barrier against waves and tides.

- Q: Composite waterproof board, is the waterproof board and geotextile stick together call it?

- Yes. Now there are mainly adhesive technology, thermal composite process, Laminating process.

- Q: How are geotextiles tested for strength and durability?

- Geotextiles are tested for strength and durability through various methods such as tensile testing, puncture resistance testing, tear resistance testing, and abrasion resistance testing. These tests involve subjecting the geotextiles to controlled forces, pressures, and wear to assess their ability to withstand different environmental conditions and loads.

Send your message to us

High Strength Polypropylene Structural Geotextile Non Woven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords