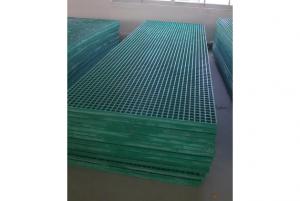

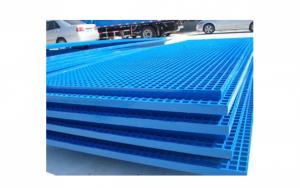

High Strength FRP Pultruded Grating with High Quality/ Good Shapes/All kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Itroduction

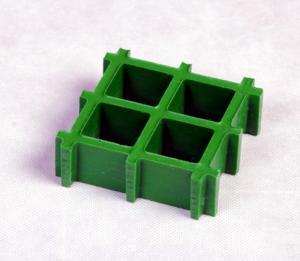

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

- Safety & Anti-slip

Electrical Insulating

Aging Resistance

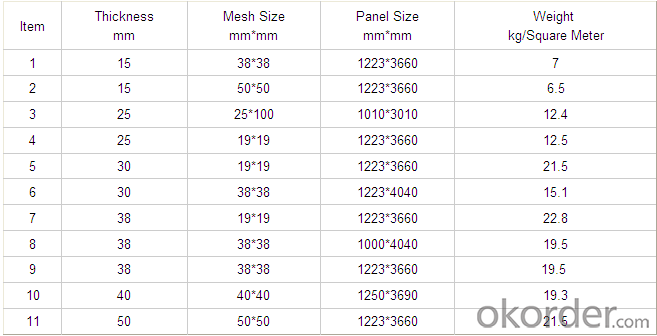

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

- long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

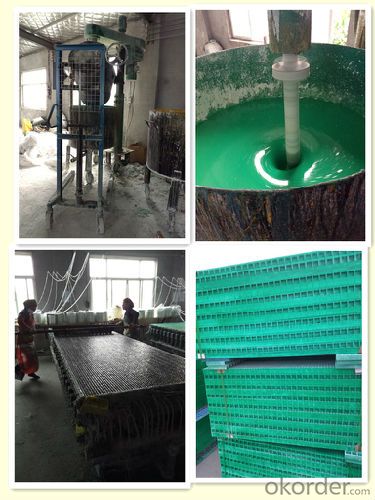

PROCESS

FACTORY

- Q: Are FRP pultrusion profiles resistant to hydrocarbons?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to hydrocarbons. The combination of various reinforcing fibers such as fiberglass or carbon fiber with a polymer matrix makes FRP materials highly resistant to chemical corrosion, including hydrocarbons. This resistance makes FRP pultrusion profiles a suitable choice for applications where exposure to hydrocarbons is expected, such as in oil and gas industry, chemical processing plants, or fuel storage facilities. However, it is important to note that the level of resistance can vary depending on the specific type of resin used in the FRP material and the concentration and temperature of the hydrocarbons involved. Therefore, it is recommended to consult with the manufacturer or supplier of the FRP pultrusion profiles to ensure their compatibility with the specific hydrocarbon environment in question.

- Q: How are FRP pultrusion profiles manufactured?

- FRP pultrusion profiles are manufactured through a highly controlled and precise process. The manufacturing process involves several steps. Firstly, the raw materials are selected, which usually include reinforcing fibers such as fiberglass, carbon fiber, or aramid, and a thermosetting resin matrix. These materials are chosen based on the desired mechanical properties of the final product. Next, the reinforcing fibers are impregnated with the resin matrix. This is typically done by passing the fibers through a bath of resin or using a resin injection system, ensuring that the fibers are completely saturated and coated. Once the impregnation is complete, the fibers are carefully pulled through a heated steel die. The die is designed to shape the pultrusion profile and provide the desired cross-sectional shape. The die is heated to a temperature that activates the resin's curing process, allowing it to harden and bond the fibers together. As the fibers pass through the die, they are continuously pulled by a set of pulling rollers or a gripper system. This pulling force helps maintain the profile's shape and dimensions and ensures a consistent and uniform product. After exiting the die, the profile enters a cooling zone, where it is cooled down using either air or water. This rapid cooling helps set the resin and stabilize the shape of the profile. Finally, the cured and cooled profile is cut to the desired length, often using automated cutting systems. Additional finishing processes like surface treatment, sanding, or painting may be applied to meet specific requirements or enhance the profile's aesthetics. Overall, the manufacturing process for FRP pultrusion profiles combines the impregnation of reinforcing fibers with resin, the shaping of the profile through a heated die, and the curing and cooling steps. This process allows for the production of high-strength, lightweight, and corrosion-resistant profiles that find applications in various industries, including construction, aerospace, automotive, and electrical.

- Q: The manufacturing process of FRP products?

- Each technique has its own characteristics. Production enterprises determine the process method in the selection, according to the basic situation of the enterprise and the production of products, such as mass production and product quality requirements, as well as the technical basis for enterprise capital and production factors such as comprehensive consideration.

- Q: Can FRP pultrusion profiles be used in the water and wastewater treatment industry?

- FRP pultrusion profiles have the capability to be utilized in the water and wastewater treatment sector. These profiles possess exceptional mechanical properties, durability, and corrosion resistance, making them suitable for a wide range of applications in this industry. The resistance to corrosion is one of the primary benefits of FRP pultrusion profiles. Water and wastewater treatment facilities often face corrosive environments, high humidity, and aggressive chemicals. Unlike traditional materials such as wood or steel, FRP pultrusion profiles are specifically engineered to endure these harsh conditions without corroding. This ensures long-term performance and reduces the need for frequent maintenance or replacement, ultimately decreasing costs. Moreover, FRP pultrusion profiles offer an excellent strength-to-weight ratio, making them perfect for structural purposes in water and wastewater treatment facilities. These profiles can be utilized as walkways, handrails, grating, ladders, and other structural components. Their lightweight nature allows for easy installation and minimizes the burden on supporting structures. Additionally, FRP pultrusion profiles are non-conductive, providing an added safety advantage in water and wastewater treatment facilities. This is especially crucial when working with electrical equipment or in areas close to water sources, as it reduces the risk of electrical hazards. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, including different shapes, sizes, and colors. This flexibility allows for greater design freedom, ensuring that the profiles can be tailored to fit the unique needs of water and wastewater treatment projects. In summary, the utilization of FRP pultrusion profiles in the water and wastewater treatment industry offers numerous advantages, including corrosion resistance, high strength, lightweight properties, non-conductivity, and design flexibility. These qualities make FRP profiles a dependable and cost-effective choice for various applications in this industry.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to wear and abrasion. The combination of the reinforcing fibers, typically glass or carbon, and the plastic resin matrix creates a material that is incredibly durable and can withstand heavy usage. The pultrusion process also ensures a homogeneous structure with fibers evenly distributed throughout the profile, further enhancing its resistance to wear and abrasion. Additionally, FRP pultrusion profiles can be engineered with specific additives or surface treatments to further enhance their resistance to wear and abrasion, making them suitable for a wide range of applications in various industries, such as construction, transportation, and marine.

- Q: Can FRP pultrusion profiles be used in the construction of highway guardrails?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of highway guardrails. FRP pultrusion profiles offer several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for highway guardrails. They have a high strength-to-weight ratio, which means they can provide the necessary structural support while being much lighter than traditional materials like steel. This makes transportation, installation, and maintenance easier and more cost-effective. Secondly, FRP pultrusion profiles are corrosion-resistant. Unlike steel, which can rust over time due to exposure to harsh weather conditions, FRP does not corrode. This makes FRP guardrails durable and long-lasting, reducing the need for frequent repairs or replacements. Additionally, FRP pultrusion profiles are non-conductive, meaning they do not conduct electricity. This is an important safety feature for highway guardrails, as it eliminates the risk of electrical shock in case of accidents involving power lines or lightning strikes. Furthermore, FRP pultrusion profiles can be manufactured in various shapes and sizes to meet the specific requirements of highway guardrails. They can be designed to have the necessary stiffness and impact resistance to withstand the forces exerted by vehicles during accidents or collisions. In summary, FRP pultrusion profiles are a suitable material for the construction of highway guardrails due to their lightweight, corrosion-resistant, non-conductive, and customizable properties. They offer a cost-effective and durable solution that can contribute to improving safety on highways.

- Q: How do FRP pultrusion profiles perform in heavy-load applications?

- The exceptional performance of FRP pultrusion profiles in heavy-load applications is well-known. These profiles can withstand substantial loads without compromising structural integrity, thanks to their high strength-to-weight ratio. The pultrusion process ensures that the fibers are uniformly distributed and aligned along the length of the profile, resulting in superior strength and stiffness. In heavy-load applications, FRP pultrusion profiles demonstrate excellent load-bearing capabilities. They possess a high modulus of elasticity, enabling them to resist deformation under heavy loads and ensuring long-term durability. Moreover, these profiles have a high ultimate tensile strength, allowing them to withstand extreme forces without breaking or deforming. Additionally, FRP pultrusion profiles exhibit corrosion resistance, making them ideal for use in harsh environments. Unlike traditional materials such as steel, FRP does not rust or corrode, ensuring a longer lifespan and reduced maintenance costs. Another advantage of FRP pultrusion profiles in heavy-load applications is their electrical insulation properties. They do not conduct electricity, making them suitable for environments where electrical conductivity is a concern. Furthermore, compared to traditional materials like steel or concrete, FRP pultrusion profiles are lightweight. This characteristic simplifies transportation and installation, while also reducing overall project costs. In conclusion, FRP pultrusion profiles excel in heavy-load applications. Their high strength-to-weight ratio, excellent load-bearing capabilities, corrosion resistance, electrical insulation properties, and lightweight nature make them the preferred choice for various industries, including construction, infrastructure, marine, and transportation.

- Q: Can FRP pultrusion profiles be used in the construction of recreational vehicles (RVs)?

- Indeed, FRP pultrusion profiles find utility in the construction of recreational vehicles (RVs). Renowned for their remarkable strength-to-weight ratio, resistance to corrosion, and durability, FRP pultrusion profiles prove to be an exemplary material for diverse applications, including RV construction. The fabrication of RVs necessitates materials that are both lightweight and robust to ensure fuel efficiency and structural integrity. FRP pultrusion profiles satisfy these requirements as they possess both lightness and high tensile strength, enabling the creation of sturdy and enduring RVs that are also lightweight and easily towed. Furthermore, FRP pultrusion profiles exhibit exceptional resistance to environmental elements such as moisture, UV radiation, and chemicals. Consequently, they prove to be suitable for outdoor applications, including RVs, where exposure to various weather conditions is inevitable. Additionally, FRP pultrusion profiles offer the advantage of effortless customization and adaptability to diverse shapes and sizes, thus meeting the design flexibility essential in RV construction. Beyond serving as structural components like frames, chassis, and supports, they can be employed for interior and exterior panels, floors, and roofs. All in all, the utilization of FRP pultrusion profiles in the construction of recreational vehicles bestows numerous benefits, including strength, durability, lightness, and resistance to environmental factors. These characteristics establish FRP pultrusion profiles as a dependable choice for RV manufacturers aspiring to fabricate high-quality, efficient, and long-lasting vehicles.

- Q: Can FRP pultrusion profiles be used in cooling towers?

- Cooling towers can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantages that make them suitable for such applications. To begin with, the corrosion resistance of FRP pultrusion profiles is exceptional, a crucial attribute in a cooling tower setting where exposure to water and chemicals is commonplace. Unlike conventional materials like steel, FRP pultrusion profiles do not rust or corrode, ensuring a longer service life and reduced maintenance expenses. Secondly, FRP pultrusion profiles exhibit a high strength-to-weight ratio, rendering them lightweight yet sufficiently robust to meet the structural demands of cooling towers. This facilitates easier installation and transportation, ultimately reducing the overall project costs. Thirdly, FRP pultrusion profiles boast excellent thermal insulation properties. As cooling towers involve the transfer of heat from water to the surrounding air, the thermal insulation provided by these profiles enhances the efficiency of the cooling process. Lastly, FRP pultrusion profiles are highly customizable and can be tailored to meet the specific requirements of cooling tower applications. They can be engineered to possess various shapes, sizes, and dimensions, ensuring a precise fit for the cooling tower design. Overall, FRP pultrusion profiles represent a dependable and cost-effective choice for cooling tower applications. Their corrosion resistance, high strength-to-weight ratio, thermal insulation capabilities, and customization options make them an excellent option.

- Q: How do FRP pultrusion profiles handle bending and flexing?

- FRP pultrusion profiles are designed to handle bending and flexing exceptionally well due to their inherent structural properties. The combination of reinforcing fibers, such as fiberglass, and a polymer resin matrix in the pultruded profiles results in high strength and stiffness. This allows the profiles to withstand bending forces without any significant deformation or failure. Additionally, the ability of FRP to withstand flexing is attributed to its high fatigue resistance, making it suitable for applications that require repeated bending or flexing movements.

Send your message to us

High Strength FRP Pultruded Grating with High Quality/ Good Shapes/All kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords