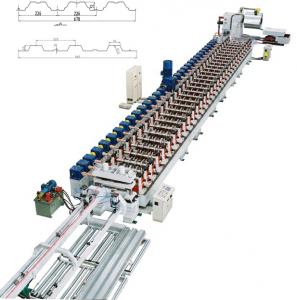

High speed wire forming machine

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

technical parameters;

1, the size of the equipment: 18000mm * 1000mm * 1500mm

2, weight: 8000kg

3, hydraulic power: 15kw motor power: 15kw shear power: 11kw

4, electrical control system: the machine adopts industrial control computer PLC

5, the transmission: by 15kw motor through a Pm500 gear drive sprocket chain, chain 1.5 inch double.

6, plate thickness: 3.0-3.5mm

7, molding: 13 row by, the mold to forming.

8, the shaft diameter: 95 mm

9, the working speed: 6000mm/min

Two, the production process:

Feeding -- -- -- -- punching pressure cutting material

- Q: What is the roll forming machine?

- The mold base elliptical motion device comprises a mold base, a slider, a slider block, a mold plate, a fixing plate, an elliptical long shaft adjusting rod and a mold base, wherein the mold base is connected with the slider through the lower part,

- Q: How is the molding machine installed?

- 1 check the machine in the transport process is damaged or deformation;

- Q: How to maintain the molding machine?

- 3 check the activities of the part, and according to lubrication requirements plus lubricants;

Send your message to us

High speed wire forming machine

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords