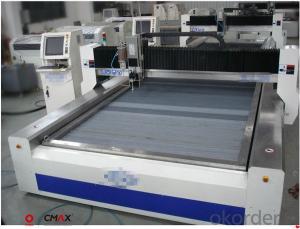

Stud and Track Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

|

Stud & track forming machine

Product of Stud & track forming machine

Technical data of Stud & track forming machine

Suitable Material | Cold-rolled steel strip and heat-treated galvanized steel strip | |

Thickness of raw material | 0.5-0.6mm (235-345Mpa) | |

Material of roller | 45# steel being quenched treatment | |

Material of cutter blade& punching die | Cr12 mould steel being quenched treatment,HRC58-60 | |

Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. | |

Forming speed | About 20m/min | |

Power Requirement | Main motor power: 5.5 Kw(Depend on final design) | |

Hydraulic station power: 5.5Kw (Depend on final design) | ||

Diameter of shaft for rollers | 55mm | |

Controlling system | Mitsubishi PLC & converter | |

Quantity of rollers | About 15 stations for main rollers | |

Weight of machine | About 6500KGS | |

Size of machine installation | About 15m x 1.7m x 1.4m | |

Our Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines |

- Q: The type of lathe tool

- Lower (640 ° C or so) and steel friction, its wear resistance is poor.Therefore, can not cut steel, but in the difficult processing of materials or vibration of the special circumstances, because the cutting speed is not high, and the tool

- Q: The Function of Machine Tool Body in CNC Machine Tool

- Its function is to support the mechanical parts and components of the body, and to ensure that these parts industry in the cutting process in the exact location.

- Q: What is the difference between turning and milling machine and other machine tools?

- Now the world famous milling and milling manufacturers are: WFL, DMG, MAZAK, Mori Seiki, Germany Hammer and China Shenyang Machine Tool Plant, Yangzhou special machine, etc.

- Q: CNC lathes 6140 and 6040 What is the difference

- 1 for single-axis automatic lathes, 2 for multi-axis automatic semi-automatic lathes, 3 for hexagonal lathes, 4 for crankshafts and camshaft lathes, 5 for vertical lathes, 6 for lathes,

- Q: What is the main work of CNC machine tools?

- CNC machine tools are the main equipment of mechanical processing, compared with ordinary machine tools is a high-performance automated machine tools, with the following obvious features:

- Q: Who can tell me the difference between instrument lathe and CNC lathe

- Therefore, the CNC lathe is currently using a wider range of machine tools.

- Q: What is the role of a CNC machine lock switch?

- The control system can logically process a program with control codes or other symbolic instructions and decode it, digitally represented by code, and input to the numerical control device through the information carrier.

- Q: What lathes are lathes?

- CNC transformation, a variety of CNC machine tools for the design and manufacture

- Q: Other types of CNC machine tools for what occasions?

- CNC machine tools can be divided into two categories: built-in and independent type

- Q: What are the operating systems for CNC lathes

- Commonly used abroad is the Japanese hair that branch, Mitsubishi, Omori, Germany, Siemens

Send your message to us

Stud and Track Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords