High Recyclable and Environmental-protection Aluminum Formwork System with Matched Accessories

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 150000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

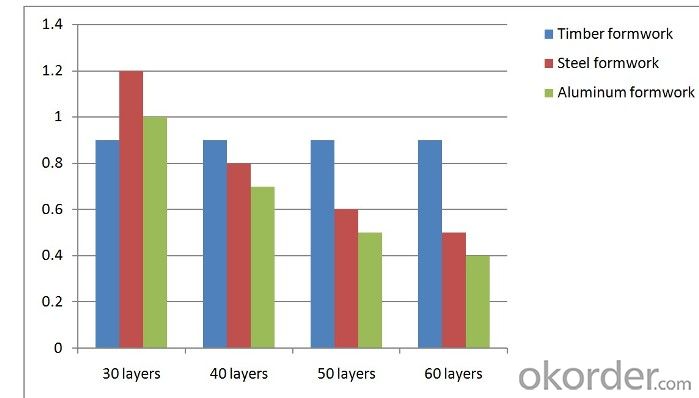

Construction Formwork Cost Comparison

Our Equipments and Capacity

We are equiped with 13 profile extrusion lines, 16 robot welding machines, 30 sawing machines of high precision and multi-dimension, 1 automatic coating line, examination center of national level which is recoganized by over 160 countries. Our monthly production capacity reaches over 150000m2. The job operation is refered to our company standard.

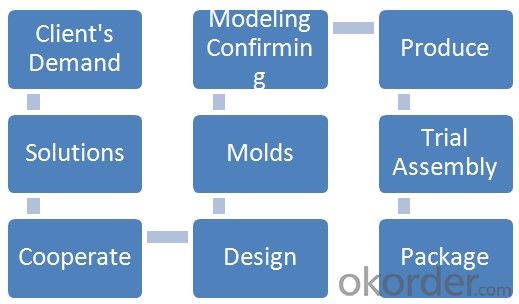

Demand Process

Why choose us?

1. Easy transaction & pleasure cooperation are our tenets all the time.

2. Every detail will be emerged in your brain clearly.

3. Don't worry about anything, we will figure it out for you with our professional technology & excellent service.

4. We aim at satisfy your demands.

5. Never the best but the most suitable plan to you, for it we are willing to put every effort determinedly.

Our Aluminum Formwork System Benefits

Economic traits

Frequent recycling and low averaging cost;High recovery rate and residual value;High efficiency of construction,short construction period;No crane,less labor cost(70% of timber and steel formwork)

High Quality

Good construction effects & quality; No troweling;Wide scope of application and strong bearing capacity;High stiffness and light weight

Environmenta Protection

Safe construction and no construction waste;Ecological and clean production;Popularization and promotion;Benefit the society

Design

International Design Team;Advanced Design Platform;Open-minded Design Concept

Service

Professional Installation Group;Committed Service,Source of Development;Stay close to the customers and provide speedy services

- Q: What is the development prospect of aluminum template design?

- High quality and stable performance: aluminum alloy template level and vertical degree can be a good guarantee, and the template itself does not absorb water, concrete molding quality is high, so no need for expensive and long plaster work, tiles can also be directly pasted in Inside and outside the wall. In addition, the aluminum alloy template system is based on architectural drawings and then accurate use of computer software and machinery made, so the construction of high precision, especially doors and windows, hydropower equipment with the location and size are accurate and effective Reduce the amount of construction materials used in the latter part of the construction, cost savings.

- Q: In the Sheng-aluminum template installation workers, how to develop prospects

- Can go to feel, the elimination rate is very high, most of them are left, remember: have the strength to be able to endure hardship, to listen to Sheng Sheng, if you do not need special money, and physical fitness is not good, labor intensity More than your imagination

- Q: What is the change in the aluminum template?

- The turnover of the aluminum template is determined by the use of performance. The use of aluminum template system to improve the overall construction efficiency of the construction industry, including in the building materials, artificial arrangements are greatly saved a lot of aluminum template, also known as aluminum alloy template, is made of aluminum alloy building templates, to solve the traditional The existence of defects in the template, greatly improving the construction efficiency.

- Q: Now the domestic use of aluminum template project more?

- Construction of aluminum alloy template construction advantages are: 1, the construction period is short, four to five days can be a layer; 2, re-use more than 200 times, effectively reduce costs; 3, artificial reduction of 30%, construction convenience, high efficiency; The template 2 times the bearing capacity, good stability, high bearing capacity;

- Q: Whether a shear wall aluminum template and wood template can be mixed

- Summary: It is recommended to use a combination of two templates in a shear wall. When the number of templates is insufficient, you can use a template alone, but it will be better than the mix.

- Q: Aluminum template of the aluminum template advantage characteristics

- Standard, versatility. Aluminum template specifications, according to the project using different specifications of sheet metal assembly; use of the template to transform a new building, just replace the 20 or so non-standard board, can reduce costs.

Send your message to us

High Recyclable and Environmental-protection Aluminum Formwork System with Matched Accessories

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 150000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords