Packaging & Delivery

| Packaging Details: | according to your requirements |

|---|---|

| Delivery Detail: | 25 days at contract signature |

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Place of Origin:Hunan, China (Mainland)

Brand Name:CNBM

Model Number:Aluminum formwork

Color::silver white

Size::customized

Sample::unavailable

Origin::Changsha,China

Port::yantian,Shenzhen

MOQ::1000m2

Thickness::4mm

Feature::recyclable

Usage::construction

Weight::22-24 kg/square meter

| Packaging Details: | according to your requirements |

|---|---|

| Delivery Detail: | 25 days at contract signature |

Aluminum formwork

1,short delivery;

2,competitive price;

3,good flatness and vercality;

4,no troweling;high recyclable rate

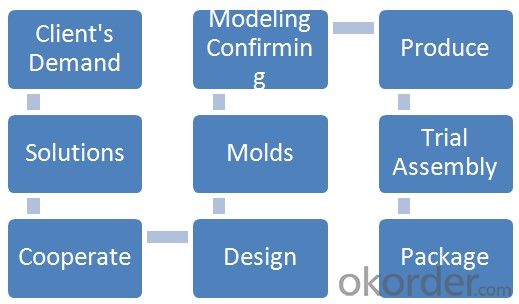

Service Process of the Al-Formwork

Pictures of SNTO Al-Formwork:

Excellent case

Why choose us?

1.”Creating better products and services for our customers” is our responsibility and mission, and our value is that “It is the real value to make value for customers”.

2.We have integrated aluminum processing chain and every step is finished in our factory, so our price would be more referential;

3.Our design team is lead by academicians of our National Academy of Engineering and we have abundant experience of aluminum formwork design. Vanke, the largest real estate enterprise in China, is our permanent partner.

Send your message to us

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords