Whole Aluminum Formwork System for High Rise Buildings

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 8000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

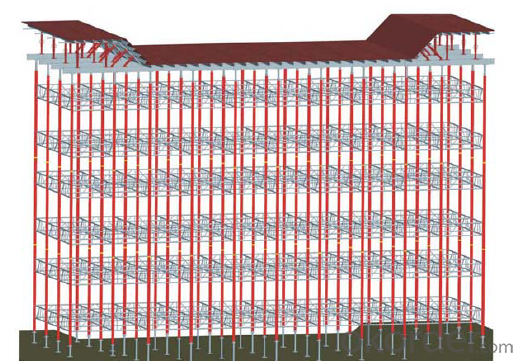

1. Structure of Whole Aluminum Formwork Description

Whole Aluminium Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort, subsequently increasing efficiency and reducing general construction time, materials and labour cost. All main components are manufactured from high grade aluminium alloy. This structural grade aluminium has exceptional properties being extremely light in weight but also heavy-duty and durable. When incorporating this into a design which utilizes standard components and allows several possible plan and elevation variables, it provides a lightweight solution for a large area slab formwork system.

2. Main Features of Whole Aluminum Formwork

-Light and easy assemble

-Simple structure.

-Competitive prices

3. Whole Aluminum Formwork Images

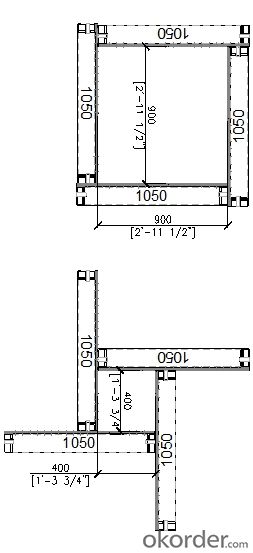

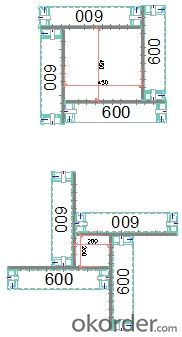

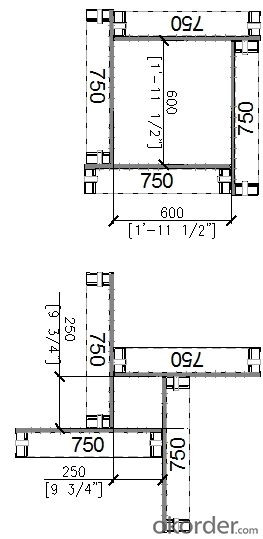

4. Whole Aluminum Formwork Specifications

1: MaximumColumn Size:900 x 900mm

(2’-11.5”x 2’-11.5”)

2: DesignConcrete Pressure: 1,800 psf (90 kN/m2)

3:StandardPanel Width 900mm, 750mm & 600mm

(2’-11.5”,2’-5.5” & 1’-11.5”)

4:StandardPanel Height: 3.0m, 2.4m, 1.2m

5. FAQ of Whole Aluminum Formwork

1) What can we do for you?

.We can ensure the quality of the Whole Aluminum Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

-Packing: wood package and adhesive tape

-Shipping: by sea

-Shipping time: Normally small orders just takes 7 business days to arrive your hand;. When it comes to the customs declaration, it may need 2weeks.

- Q: What is the development prospect of aluminum template design?

- Easy to disassemble, high construction efficiency: aluminum alloy template for the existing metal template in the lightest, single can be free to move, install, remove and transfer, the workers can easily assembled. Each template, components are in the same location on each floor, the workers only need a simple training, a short period of time can be proficient in the construction process. And the installation and removal process, just human, no other machinery, simple operation, easy construction.

- Q: In the Sheng-aluminum template installation workers, how to develop prospects

- Sheng Tong on my feeling is the same as prison, in addition to front-line staff (prisoners), what is the leadership (guards), every day is the workshop, dormitory, dinner time is only half an hour, the company provides working hours if 12 hours, The time to stay in the workshop every day in more than 13 hours, especially hard to force, can not stand the tube, temper a little irritable advice do not go, afraid you can not control their own K

- Q: What is the change in the aluminum template?

- Advantages of aluminum alloy template: 1. Construction period is short: aluminum alloy building template system for the quick-release mold system, a set of normal construction of the template can reach four or five days a layer, greatly saving the construction unit management costs (currently under construction project in Macau - TN27 public housing construction up to Three days a layer). (6063-T6 or 6061-T6), a set of template specifications can be used to reverse the use of 300-500 times the use of aluminum alloy profiles, the use of aluminum, Above, the average use of low cost. Easy construction, high efficiency: aluminum alloy building template system assembly is simple, convenient, the average weight of 30KG / m2, completely by the artificial assembly, do not need any mechanical equipment assistance (workers usually only need a wrench or a small hammer, convenient ), Skilled installation workers can install 20-30 square meters per person per day (compared with the wooden mold: aluminum mold installation workers only need to install wood workers 70-80%, and do not need skilled workers, just before the installation of the construction Personnel can carry out simple training). Good stability, high bearing capacity: aluminum alloy building template system all parts are made of aluminum alloy plate assembly, the system assembled to complete the formation of a whole frame, the stability is very good; bearing capacity can reach 60KN per square meter.

- Q: Now the domestic use of aluminum template project more?

- Traditional template construction cycle is long, dirty, chaotic, noise, resulting in a large number of construction waste, building materials, resource consumption, high labor costs, and the construction quality is difficult to guarantee. Compared to the traditional construction methods, the use of aluminum alloy template floor can be a whole casting molding, flatness and verticality better, smooth surface plastering, and can be reused more than 200 times. This can not only save a lot of manpower, material, but also can be recycled, energy saving and environmental protection, significant economic benefits.

- Q: Whether a shear wall aluminum template and wood template can be mixed

- The high strength and stability of the aluminum template are good, and the surface roughness of the concrete is high and the precision is high, which can be removed from the surface. The fixed method is simple and quick,

- Q: Aluminum template of the aluminum template advantage characteristics

- Aluminum template system components need to be designed according to the characteristics of the floor, the design of technical staff capacity requirements are higher. Approximately 80% of the modules in the aluminum template system can be recycled in multiple projects, while the remaining 20% can only be recycled in a class of standard floors, so the aluminum template system is suitable for high-level buildings with high levels of standardization. And villa group.

Send your message to us

Whole Aluminum Formwork System for High Rise Buildings

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 8000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords