High Quality Seamless Steel Pipe with Best Price from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DETAILS

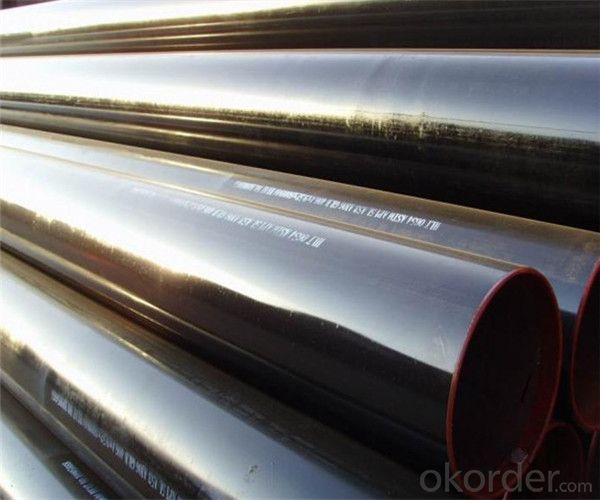

1.Structure of Seamless Steel Pipe Description:

A large amount of Seamless Steel Pipes is offered to the clients at cost effective rates. These pipes are extremely durable, resistant to corrosion and have high tensile strength. Our pipes are used in nuclear plants, power plants, refineries and construction industry across the country. Furthermore, we are capable of providing these seamless pipes to the clients in bulk quantity.

2.Main Features of the Steel Pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

3.Seamless Steel Pipe Specification:

| Standard: | GB, DIN, ASTM,ASME, ASTM A106-2006, ASTM A53-2007 |

| Grade: | 10#,20#, 45#, 16Mn |

Thickness: | 8 - 33 mm |

| Section Shape: | Round |

| Outer Diameter: | 133 - 219 mm |

| Place of Origin: | Shandong, China (Mainland) |

| Secondary Or Not: | Non-secondary |

| Application: | Hydraulic Pipe |

| Technique: | Cold Drawn |

| Certification: | API |

| Surface Treatment: | factory state or painted black |

| Special Pipe: | API Pipe |

| Alloy Or Not: | Non-alloy |

| Length: | 5-12M |

| Outer Diameter: | 21.3-610mm |

| Packaging Details: | Seaworthy packages, bundles wrapped with strong steel strip |

| Delivery Detail: | 15-30 days after received 30% TT |

4.Product pictures

5.FAQ of Seamless steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust.

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: Are steel tubes and round steel in weight or length when purchased?

- A large amount of words is calculated by weight, less is usually calculated. According to the length between the length and quality of a material is usually a scaling. Steel belongs to the section, with the length of valuation, according to the classification of wall thickness and diameter; round steel belongs to building materials, mostly for the amount of weighing per ton of valuation, a small amount of more than according to the length multiplied by the conversion ratio of weight to that theory. But the latter is the valuation of tons of steel products between the uneven thickness, with uniform proportion will produce larger price difference, so the general price of different manufacturers are not the same, mostly depends on the quality, to a certain extent is to balance the diameter difference.

- Q: Can steel pipes be used for underground sewer systems?

- Yes, steel pipes can be used for underground sewer systems. They are commonly used due to their strength, durability, and resistance to corrosion, making them suitable for handling wastewater and underground installation.

- Q: What is the maximum temperature that steel pipes can withstand?

- The maximum temperature that steel pipes can withstand depends on the grade and type of steel used. Generally, carbon steel pipes can withstand temperatures up to 1000°C (1832°F), while stainless steel pipes can handle temperatures up to 1200°C (2192°F). However, it is essential to consult the specific specifications and guidelines provided by the manufacturer for accurate temperature limits.

- Q: What are the different types of joints used to connect steel pipes?

- There are several types of joints commonly used to connect steel pipes, including threaded joints, welded joints, flanged joints, and grooved joints.

- Q: What are the main types of steel pipe ah? How to judge which kind of steel pipe performance is better?

- Steel pipe according to the production method can be divided into two categories: seamless steel pipe and pipe joints, pipe joints as welded steel pipe.1. seamless steel tube according to the production methods can be divided into: hot-rolled seamless pipe, cold drawn tube, precision steel tube, heat expansion tube, cold spinning tube and extrusion tube.Seamless steel tubes are made of high quality carbon or alloy steel. They are hot-rolled and cold-rolled (drawn).Bundled steel pipe

- Q: How are steel pipes used in geothermal energy systems?

- Steel pipes are used in geothermal energy systems to transport the hot water or steam from the underground reservoir to the surface. These pipes are resistant to high temperatures and corrosion, ensuring the safe and efficient transfer of geothermal fluids. Additionally, steel pipes provide durability and strength, making them suitable for the harsh conditions of geothermal environments.

- Q: How do you measure the thickness of a steel pipe?

- Different methods can be used to measure the thickness of a steel pipe, depending on the required precision and available tools. Here, we present three commonly used approaches: 1. Calipers or Vernier Calipers: These are widely used and straightforward tools for measuring thickness. Place the jaws of the calipers on both sides of the pipe, ensuring they are perpendicular to the surface. Gently close the jaws until they touch the pipe, and then read the measurement on the caliper scale. 2. Ultrasonic Thickness Gauge: This method provides more accurate results and is commonly employed in industrial settings. An ultrasonic thickness gauge emits high-frequency sound waves that penetrate the steel pipe. By measuring the time it takes for the sound waves to bounce back, the gauge calculates the pipe's thickness. Before taking the measurement, ensure that the pipe surface is clean and smooth. 3. Magnetic Thickness Gauge: This method is specifically designed for measuring the thickness of ferrous materials like steel. The gauge incorporates a small magnet that adheres to the pipe surface. By applying a magnetic field, the gauge determines the distance between the magnet and the base plate. This distance corresponds to the thickness of the steel pipe. It is important to consider that each method has its own limitations in terms of accuracy. The choice of measurement technique should be based on the desired precision, availability of tools, and the specific requirements of the application.

- Q: What's wrong with the 3PP anticorrosive steel tube?

- That is, polypropylene corrosion resistant coating of steel pipe, the biggest feature of this anti-corrosion coating is good heat resistance.

- Q: Are steel pipes suitable for use in nuclear power plants?

- Yes, steel pipes are suitable for use in nuclear power plants. They are commonly used in various systems such as cooling, steam, and reactor coolant systems due to their high strength, durability, and resistance to corrosion. Additionally, steel pipes can withstand the high pressure and temperature conditions present in nuclear power plants, making them a reliable choice for this critical infrastructure.

- Q: What is the difference between steel pipes and concrete-lined pipes?

- The main difference between steel pipes and concrete-lined pipes lies in their composition and protective features. Steel pipes are typically made entirely of steel, providing strength and durability. On the other hand, concrete-lined pipes consist of a steel pipe coated with a layer of concrete. This lining offers additional protection against corrosion and abrasion. While steel pipes are more suitable for high-pressure applications and offer better resistance to external factors, concrete-lined pipes are commonly used in wastewater systems to prevent corrosion and extend the lifespan of the pipe.

Send your message to us

High Quality Seamless Steel Pipe with Best Price from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords