High-Quality PPR Fitting Socket Plastic Tubes - Compliant with Food Hygiene Regulations and Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 9000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

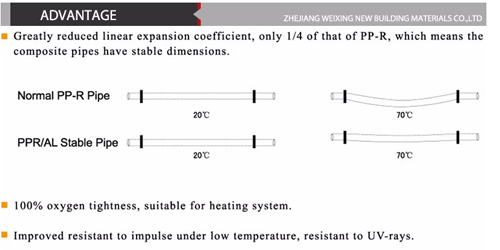

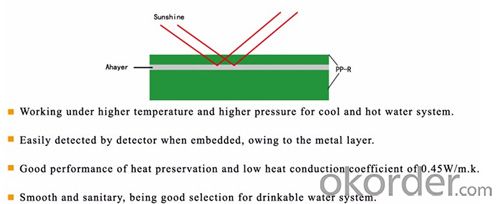

Advantages of PPR pipe

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

FAQ

Chemical Structure of PPR

PP random copolymer of ethylene molecules generally contain 1 7% (by weight) and 99-93% (by weight) of propylene molecules. On the polymer chain, ethylene molecules randomly inserted in the middle of the propylene molecules. In such a random or statistical copolymers, the majority (typically 75%) are single molecules of ethylene incorporated into the insert, called the X3 group (three consecutive ethylene [CH2] are sequentially arranged in the main {TodayHot} chain), which can also be seen as an ethylene molecule is inserted in the middle of two propylene molecules.

Another 25% of the ethylene molecule is inserted more incorporated into the main chain, also known as X5 groups, since there are five consecutive methylene groups (two ethylene molecules together two propylene molecules inserted in the middle). It is difficult to distinguish between X5 and higher groups such as X7, X9 and so on. In view of this, the XS and higher ethylene content groups together counted as> X3%.

Randomness ratio X3 / X5 can be measured. When the above percentage X3 group is large, it will significantly reduce the crystallinity of the copolymer, the final properties of this random copolymer influence. Ethylene copolymer has very high levels of crystallinity of the polymer, similar to the effect when high random polypropylene content.

Unlike random copolymer PP homopolymer as the polymer backbone randomly inserted into the ethylene molecules hindered crystalline arrangement of polymer molecules. Copolymers of a decreased change in crystallinity caused by physical properties: PP homopolymer and random copolymer is reduced in rigidity as compared to improve impact resistance, better transparency. Ethylene copolymers also lower melting temperature, which has become in some ways the advantages of their use.

Random copolymer may contain more leather extract and random PP, as well as a much higher ethylene content of the polymer chain. This higher leather extract content may, depending on the polymerization process, to varying degrees in all the goods copolymer materials and meet the Federal Food Administration (FDA) on food contact {HotTag} specified on the cause difficult.

Manufacturing method of PPR pipes:

Ethylene / propylene random copolymer and ethylene molecules is carried out by polymerization of propylene molecules simultaneously obtained, the use of the reactor and the production of PP homopolymer same. Ethylene propylene molecular ratio of small molecules is faster than the reaction (reactive approximately ten times) propylene. This stereospecificity of the catalyst activity is increased and decreased, resulting in increased generation amount of atactic polypropylene. In order to reduce the generation of such random thereof, the reaction temperature needs to be reduced, thereby reducing the activity of the catalyst, and to reduce the content of the final product ppr sizes random isomer, to obtain a product having a more balanced performance.

Ethylene content (> 3%) random copolymer in the production process more difficult to deal with, it is difficult to carry out polymerization in hexane diluent, since the two by-products of the reaction (the amount of atactic polypropylene and ethylene-containing high copolymer) can be dissolved in hexane. This bulk liquid propylene polymerization reaction is the same, in spite of low solubility. Diluted with hexane to produce a large number of process by-product, it must be separated out in hexane in the recycle phase, which will increase the total cost of production, but was able to get close sparingly soluble polymer component of the cleaner. In the bulk polymerization process, these impurities will remain in the polymer, and trouble in handling sheet-like material. Moreover, the final copolymer products contain more soluble impurities. Second washing with an organic solvent, most of the impurities can be removed, but will increase the overall cost of production of the copolymer. In general, a high content of by-products, the flake random copolymer will become more viscous, when the ethylene content higher than 3.5% (by weight), the problem is more prominent.

- Q: why does water bend when put in a plastic tube?

- Your getting a bit of a late start on your homework, aren't you?

- Q: Can plastic tubes be used for air ventilation systems?

- Yes, plastic tubes can be used for air ventilation systems. They are commonly used in various applications, including residential and commercial ventilation systems. Plastic tubes offer advantages such as easy installation, lightweight design, corrosion resistance, and cost-effectiveness. However, it is important to choose the appropriate type and quality of plastic tubes to ensure they meet the necessary safety and performance standards for ventilation purposes.

- Q: Do plastic tubes have any limitations in terms of shape or design?

- Yes, plastic tubes do have limitations in terms of shape and design. They are typically manufactured in cylindrical shapes due to the nature of their production process, which involves extrusion or injection molding. While it is possible to create variations such as oval or rectangular tubes, these options are more limited and less common. Additionally, complex designs or intricate shapes may not be feasible or cost-effective to produce using plastic tubing.

- Q: I hate the plastic tubes. They're fiddly awkward to use, especially as they get near running out. Metal was SOOO much easier. Just roll up the tube it stays rolled up. Just squeeze the metal it doesn't pop right up as soon as you release the pressure, but stays down. Basically metal packaging was right for the job. Plastic tubes are a poor, inadequate alternative, I hate them.It can't be due to cost, since so many drinks are still sold in metal cans, if it was down to the cost all the metal cans would be replaced with cheaper plastic alternatives, but they're not.So what is the reason it's only plastic for toothpaste now?

- It is due to cost. Drinks used to be sold in steel cans and glass bottles, now they are sold in aluminum cans and plastic bottles, due to cost. You can buy a plastic clip to put on the toothpaste tube to solve your problem.

- Q: The connection between the plastic tube and the metal tube seems not so simple

- Plastic pipes with outer diameter as standard, usually 20, 32, 40, 50, 60, 70, 110, etc., all with inner diameter and corresponding wall thickness

- Q: What kinds of plastic pipes are available? Which ones are free to deform and turn?! At the same time can bear the pressure of tap water!

- According to various plastic molding methods, can be divided into film pressure, lamination, injection, extrusion, blow molding, casting plastics and reaction injection plastics and other types.

- Q: Can plastic tubes be used for industrial labeling?

- Yes, plastic tubes can be used for industrial labeling. They are commonly used for labeling in various industrial settings due to their durability, flexibility, and resistance to moisture, chemicals, and UV radiation. Plastic tubes provide a reliable and cost-effective solution for labeling products, equipment, and components in industrial environments.

- Q: How are plastic tubes labeled with expiration dates?

- Plastic tubes are typically labeled with expiration dates using either stickers or inkjet printing directly on the surface of the tube.

- Q: Hey y'all, I've seen a few people at my hospital with charms made from medication vials and IV tubing hanging on their stethoscopes... Does anyone know how to make these??PS: I'm well aware of infection control issues associated with dangling things... I'm looking to make keychains like these.

- if you combine tahese sources, you mightlearn what you need. Plastic tube jewelry and some med charms?

- Q: How are plastic tubes filled with adhesives or sealants?

- Plastic tubes filled with adhesives or sealants are typically filled using a specialized filling machine. The machine is equipped with a nozzle that is inserted into the tube's opening, and the adhesive or sealant is pumped into the tube under pressure. Once the desired amount is filled, the nozzle is removed, and the tube is sealed to prevent any leakage.

Send your message to us

High-Quality PPR Fitting Socket Plastic Tubes - Compliant with Food Hygiene Regulations and Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 9000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords