High-Quality PPR Male Threaded Socket Plastic Tubes for Water Supply with Safety Guarantee

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

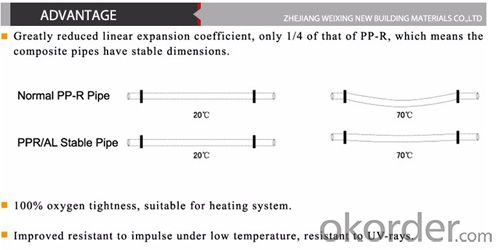

Advantages of PPR pipe

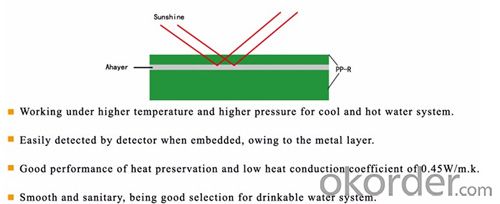

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

Features of PPR

PPR pipe also known as three polypropylene pipe using a random copolymer polypropylene by extrusion become pipe, injection molded into the tube. PPR pipe is the development and application of new plastic pipe products in the early 1990s of the European. The late 1980s, PPR is the use of a gas phase copolymerization process so that about 5% PE in the molecular chain of PP random homogeneous polymerization (random copolymer) and a new generation of pipe materials. It has a good impact resistance and long-term creep performance.

PPR pipes have the features of light weight, corrosion resistance, no scaling, long life, but also have the following characteristics:

1. Non-toxic health: raw material molecule only carbon and hydrogen elements, not only for hot and cold water pipes, can be used to clean drinking water systems;

2. Energy-saving insulation: pipe thermal conductivity 0.21W / MK, steel is only 1/200;

3. Better heat resistance: PPR pipe Vicat softening point of 131.5 ℃, the maximum working temperature up to 95 ℃, can meet the water supply and drainage requirements specification hot water system;

4. Long life: PPR operating temperature 70 ℃, working pressure (PN) conditions under 1.0Mpa life of up to 50 years at room temperature (20 ℃) the service life of up to 100 years;

5. Install reliable connection: PPR pipe has good weld ability, pipe fittings can be used hot-melt and fused connections, easy installation, reliable joints, the strength of joints is greater than the strength of the pipe itself;

6. Recyclable materials: does not affect product quality.

How to choose a safe and economical PPR pipe?

1. Note that the overall pipeline utilization factor C (that is, the safety factor) is determined. General case, and long-term continuous use temperature is less than 70 ℃, optional C is equal to 1.25. On important occasions and long-term continuous use temperature of greater than or equal to 70 ℃, and is likely to run at a higher temperature for a long time, an optional C = 1.5;

2. For cold water (≤40 ℃) system, the choice of PN1.0 ~ 1.6Mpa pipe, fittings, hot water system for the selection of greater than or equal to 2.0Mpa pipe, tube.

- Q: Are plastic tubes suitable for packaging electronics or electrical components?

- Yes, plastic tubes are suitable for packaging electronics or electrical components. They provide excellent protection against moisture, dust, and static electricity, ensuring the safety and integrity of the components during storage and transportation. Additionally, plastic tubes can be easily customized to accommodate various sizes and shapes of electronics, offering flexibility and convenience in packaging.

- Q: Which companies manufacture GOOD QUALITY plastic and rubber tubing for use in a molecular biology lab, ie. for condensers, circulators, etc

- Tygon is a brand name for a variety of flexible tubing. Tygon is a registered trademark of Saint-Gobain Corporation. It is an invented word, owned and used by Saint-Gobain and originated in the late 1930s. Tygon is produced in 3 countries but sold throughout the world. Tygon Tubing is used in many markets including food and beverage, chemical processing, industrial, laboratory, medical, pharmaceutical, and semiconductor processing. There are many formulations of clear, flexible, Tygon tubing. The chemical resistance and physical properties vary among the different formulations. See link for types and suppliers.

- Q: What are the common thicknesses for insulation plastic tubes?

- The common thicknesses for insulation plastic tubes vary depending on the application and industry. However, some commonly available thicknesses for insulation plastic tubes range from 1/8 inch (3mm) to 1 inch (25mm) or more.

- Q: This is for an engineering class. The tower cannot have any supports and must extend horizontally over 7 feet without touching the floor. It can bend. It is also going to be extended from a 1.5 inch plastic tube. Please answer ASAP! Need answer before 11/28/07. Thanks

- You need to provide a sketch of some kind. Cannot visualize your problem.

- Q: What are the advantages of using plastic tubes in packaging?

- There are several advantages of using plastic tubes in packaging. Firstly, plastic tubes are lightweight, making them easy to transport and handle. Secondly, they are durable and provide excellent protection for the contents inside, preventing damage or breakage. Additionally, plastic tubes are resistant to moisture and can be made airtight, ensuring the products inside remain fresh and uncontaminated. Furthermore, plastic tubes offer flexibility in design and can be customized to suit various shapes, sizes, and labeling requirements. Lastly, plastic tubes are cost-effective compared to other packaging materials, making them a popular choice for many businesses.

- Q: Where can i get a spare light saber blade(just the tinted plastic tube)a phone # or url would help?

- I okorder does conversions they put in a stronger removable blade specifically for dueling. So if you use your Force FX for fighting. they will be a great place to go. They have many different kinds of blades so you will need to contact them for what you need specifically.

- Q: Are plastic tubes suitable for outdoor signage?

- No, plastic tubes are not suitable for outdoor signage as they are not weather-resistant and may deteriorate or fade when exposed to outdoor elements.

- Q: how do you get 2 pieces of plastic tube unstuck?

- Are they PVC? Is there a joint or fitting over them (a bigger piece of PVC that both tubes fit into)? Did someone else assemble it (or did you assemble it with a PVC glue)? If you answered yes to all three of these, you are in trouble. PVC is often assembled with glues which can be very difficult or impossible to undo. It is often easier to just cut the PVC and then extend it with a new joint.

- Q: Do plastic tubes have any limitations in terms of compatibility with other packaging materials?

- Yes, plastic tubes do have limitations in terms of compatibility with other packaging materials. Some plastics may not be compatible with certain chemicals or substances, leading to potential reactions or degradation of the packaging material. Additionally, plastic tubes may not be suitable for certain packaging methods or applications, such as those requiring high temperatures or pressure. It is important to consider the specific requirements and properties of the packaging material and its compatibility with other materials to ensure an effective and safe packaging solution.

- Q: And does Bon Jovi use it in songs such as Livin' On a Prayer? B/c is sounds like it.

- It is called a talk box, the company heil makes the original one that peter frampton used in the 70's, it is a pain to hook up. there is a fairly newer one on the market called a banshee talk box, basically there is a speaker in the box on the floor it puts out your guitar up thru the plastic tube, when you put your mouth on it. you can manipulate the sound and it is picked up by the microphone.

Send your message to us

High-Quality PPR Male Threaded Socket Plastic Tubes for Water Supply with Safety Guarantee

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords