Plastic Tubes PPR Female Plumbing Tee Compliant with Food Hygiene Regulations and Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 300 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

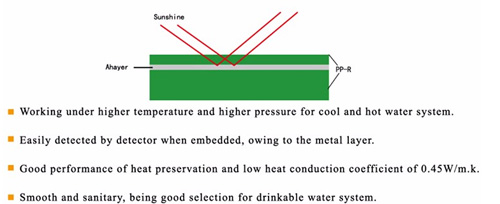

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

Development of PPR Pipes

Compared with traditional cast iron pipe, galvanized steel pipes, cement pipes and other pipes, PPR pipes have the advantages of energy-saving, environmental protection, high-strength lightweight, corrosion-resistant, smooth wall does not scale, simple construction and maintenance and long lasting. PPR pipe and fittings, plastic water pipe are widely used in building water supply and drainage, urban and rural construction, municipal, industrial and agricultural areas of water supply and drainage, city gas, electricity and cable jacket, industrial fluid transport, agriculture and irrigation.

In recent years, with the increasing market demand of construction, municipal engineering, hydraulic engineering, agricultural and industrial, Chinese ppr pipes manufacturers have shown a trend of rapid development. According to the survey, plastic pipe production capacity of which in 2009 was 5.804 million tons increased of 18.9% in 2010, from January to September of plastic pipe production of 5.528 million tons, an increase of 28.23%. Meanwhile, with consumer products, environmental protection, health, durability and other aspects of quality requirements continue to increase, China's plastic pipe production increased at the same time, polyethylene pipe product quality has improved continuously, the industry continues to accelerate technological progress, growing scale enterprises brand new materials, new structures are emerging varieties, advanced system design concepts emerging, product functionality more obvious, further broaden the application areas. Analysts believe that China is currently the proportion of plastic pipe market share in the entire pipeline has exceeded 30%.

By 2015, China in new construction, renovation, expansion project, 85% of the building drainage pipes plastic water pipe, building rainwater drains 80% of plastic pipes, plastic water pipe use urban drainage channel reaches 50 percent, building water supply, hot water supply and heating tube 85% of the plastic pipe, city water pipe (DN400mm or less) 80% of the plastic tube, rural water supply line 90% of the plastic water pipe city gas plastic pipe (low pressure pipe) volume applications up to 40%, building wire threading jacket pipe 90% of the plastic tube. It is predicted that China ppr pipe and fittings production during the second five will remain at about 10% growth rate, by 2015, China is expected to produce plastic pipe will be close to 12 million tons of plastic pipe market share in China in more than various types of pipes 60%.

PP-R pipes also called random copolymer polypropylene. It uses random copolymer polypropylene by extrusion become pipe, injection molded into the tube. In the early 1990s on European, PP-R pipes are the development and application of new plastic pipe products. PP-R is the late 1980s, using a gas phase copolymerization process so that the molecular chain of about 5% PP random evenly polymerization (random copolymer) and a new generation of pipe materials. High strength, impact resistance and has good long-term creep performance. At the same time the ppr fittings have excellent resistance to chemical corrosion, at room temperature, insoluble in any known solvents, so in addition to home improvement, chemical plants and other places more suitable for transportation of chemical fluids. Life of up to 50 years, the market has not any cheaper materials can replace it.

- Q: How are plastic tubes filled with products?

- Plastic tubes are typically filled with products using various methods such as manual filling, semi-automatic filling machines, or fully automated filling lines. The products are usually pumped or poured into the tubes through the open end, and then sealed using heat or a mechanical process.

- Q: Are plastic tubes suitable for underwater applications?

- Yes, plastic tubes can be suitable for underwater applications. Many types of plastic materials, such as PVC or polyethylene, are water-resistant and can withstand the pressure and conditions found underwater. Additionally, plastic tubes can be designed to be corrosion-resistant, lightweight, and flexible, making them ideal for various underwater uses, including plumbing, irrigation, or underwater exploration. However, the specific type and quality of plastic used should be carefully chosen to ensure durability and compatibility with the underwater environment.

- Q: Do plastic tubes have any limitations in terms of shape or design?

- Yes, plastic tubes do have limitations in terms of shape or design. While they can be manufactured in a variety of shapes and sizes, there are certain constraints due to the material's flexibility and molding capabilities. Complex or intricate designs may be challenging to produce with plastic tubes, and their shape may be limited to primarily cylindrical or tubular forms.

- Q: i have to get it for a science roller coaster project. We are building a model roller coaster.

- Cardboard tubing is available at most shipping retailers (FedEx, Mailboxes Etc., and so forth). Foam pipe insulation and clear tubing (clear plastic hose?) can be found at most home improvement retailers (Lowe's, Home Depot, etc.) in the plumbing department.

- Q: I'm on vacation right now with my family. I'm on my period and we're going swimming. All I brought was pads. Yesterday I forgot to wear one because earlier in the month it came really light and I figured that was it. But yesterday it went through my pants and came on full force. I don't think anyone noticed but I decided I needed to wear a tampon in my swim suit instead of a pad to be safe. So I found some in the cabinet. I put it in correctly and I'm currently in the car going to the lake. But the tampon is sitting inside me with the plastic tube in it and I can feel it it doesn't hurt but I can feel it. I removed the first plastic cover but there's another one? And it wouldn't easily come off so idk? It's tampax pearls and I'm nervous, I've always worn pads and not tampons.

- Did you read the instructions? When you put in the tampon you put it in the push on the skinny stick part to get the tampon out of the applicator. Then you pull the applicator out and just the tampon will be inside you.

- Q: Can pur plastic pipes be used as drinking water pipes?

- Pur plastic pipes can not be used as drinking water pipes. 1 low strength, 2 easily decomposed. 3 does not guarantee hygiene

- Q: What are the different shapes of plastic tubes available?

- There are various shapes of plastic tubes available, including round, square, rectangular, oval, and triangular.

- Q: This is for silver eagles, silver maple leafs, and silver rounds that i have stored in plastic coins tubes. I have been using cotton balls stuffed into the top to take up air space and prevent sliding around; but will this damage the silver?

- Cotton balls work fine, and won't damage the silver IF they are clean and you don't shake the tubes a lot. (Coin companies use cotton balls when shipping coins in tubes if needed.)

- Q: What are the different types of closures available for plastic tubes?

- There are several types of closures available for plastic tubes, including flip-top caps, screw caps, snap-on caps, dispensing caps, pump caps, and squeeze tops. These closures serve different purposes and are used based on the specific requirements of the product being packaged and the ease of use desired by the consumers.

- Q: I have a big section of vinyl/plastic tubing does anyone have any ideas for what i could make out of it? Thanks in advance!

- You can use it as a storm drainage from your house to the main sewer line, you can use it too as false column in your house as additional decoration, can be use as a form of a circular post, can be use as backyard bench.

Send your message to us

Plastic Tubes PPR Female Plumbing Tee Compliant with Food Hygiene Regulations and Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 300 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords