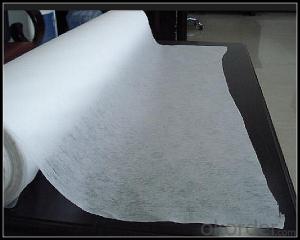

High Quality Non Woven Geotextile Fabric - Polypropylene Construction Geotextile at Cheap Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Woven and Non Woven Geotextiles are robust and durable fabrics designed to increase soil stabilization and ground support in a given location. Typically made from polypropylene fibers, these geotextiles are high in strength to allow for maximum slope support, stabilization and erosion control. Options include a felt-like nonwoven material as well as a woven polypropylene blend.

Property:

1.High strength ; low deformation.

2. Durability: steady property, not easy to resolved, airslaked and keep the original property long term.

3. Anti-erosion: anti-acid, anti-alkali, resist insects and mould.

4. Permeability: the woven geotextile can control the sieve size to retain permeability.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

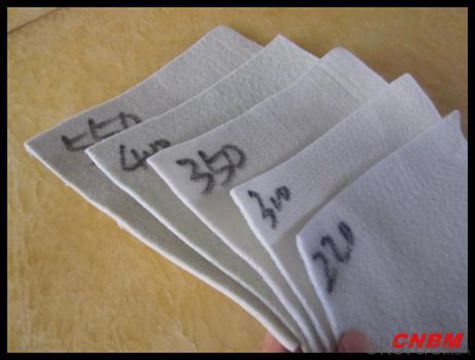

A: Yes, please check the pictures:

- Q: What are the advantages of using geotextiles in waste containment systems?

- Geotextiles offer several advantages in waste containment systems. Firstly, they act as a barrier, preventing the migration of contaminants from the waste site into the surrounding environment. Secondly, they provide stability and reinforcement to the waste containment structure, enhancing its strength and durability. Additionally, geotextiles facilitate proper drainage and filtration, allowing for the efficient removal of excess water and leachate. They also minimize soil erosion, which is crucial for long-term stability. Overall, geotextiles improve the performance and longevity of waste containment systems while minimizing environmental risks.

- Q: I am currently displaying my geotextile samples in a brochure type display holder.but its not really working for holding a large amount. i can only fit about 8 in each holder. not very practical. i have been perusing google and stuff but am not coming up with much. i see very large cases, or the same displays i have now. does anyone have any ideas????PS This would be sitting on the top ledge of my desk so i am not really wanting anything that stands on the floor. hopefully someone else out there can help!

- Brittney420? My type of woman! We should hang out, my name is Art and you can message me if you want my number. I'm 6' 160 Pounds, I got a job, a HUGE house and a dog. Sorry I couldn't answer your question though.

- Q: Can geotextiles be used in riverbank stabilization projects?

- Yes, geotextiles can be used in riverbank stabilization projects. Geotextiles are often employed in these projects to prevent erosion and provide soil stabilization along riverbanks. They help to reinforce the soil, control water flow, and protect against scouring, making them an effective solution for riverbank stabilization.

- Q: How do geotextiles contribute to sustainable drainage systems?

- Geotextiles contribute to sustainable drainage systems by providing effective filtration and separation of different soil layers, preventing clogging and promoting efficient water flow. They also enhance soil stability, reducing erosion and maintaining the integrity of the drainage system over time. Additionally, geotextiles can be made from recycled materials, reducing waste and promoting sustainability in drainage infrastructure.

- Q: Geotextile price specific how to develop?

- Each type of product in the market before the sale, the pricing will take into account all aspects of the factors, very strict and careful investigation, geotextile is also true. The first is the product quality is the second product specifications and standards to Hongxiang new material short wire geotextile, for example, sub-weight (80-1500g / ㎡), the quality standard is a requirement, divided into non-standard, by White A, Sinochem, ordinary GB, Paul GB, Dahua GB and so on. Ton price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton. 187 & lt; 6600 & lt; 5604

- Q: What are the key considerations for geotextile installation in areas prone to landslides?

- The key considerations for geotextile installation in areas prone to landslides include understanding the slope stability and soil characteristics, selecting the appropriate type and strength of geotextile, ensuring proper anchoring and connection methods, implementing effective drainage systems, and regularly monitoring and maintaining the geotextile system.

- Q: How do geotextiles help in preventing soil liquefaction?

- Geotextiles help in preventing soil liquefaction by providing stability and reinforcement to the soil. They act as a barrier and restrict the movement of soil particles, thereby reducing the potential for liquefaction. Additionally, geotextiles enhance the drainage capacity of the soil, allowing water to flow through and preventing the buildup of excess pore pressure, which is a major factor leading to liquefaction.

- Q: What are the key factors affecting the clogging behavior of geotextiles?

- The key factors affecting the clogging behavior of geotextiles include the type and size of particles in the soil or water, the flow rate, the duration of exposure, and the properties of the geotextile itself such as pore size, density, and surface roughness. Other factors may include the presence of chemicals or organic matter in the soil or water, as well as environmental conditions such as temperature and moisture content.

- Q: How are geotextiles used in agricultural applications?

- Geotextiles are used in agricultural applications to provide erosion control, promote soil stabilization, and enhance draining capabilities. They are often used in the construction of retaining walls, terraces, and embankments to prevent soil erosion and maintain the integrity of the structures. Additionally, geotextiles can be used as a protective layer over the soil, allowing water to pass through while preventing weed growth and conserving moisture.

- Q: How do geotextiles contribute to soil stabilization in mining areas?

- Geotextiles contribute to soil stabilization in mining areas by providing reinforcement and preventing erosion. These synthetic materials are placed within the soil to enhance its strength and stability, reducing the risk of landslides and soil disturbances. Geotextiles also act as a barrier, preventing the migration of fine particles, thereby improving soil filtration and preventing contamination of nearby water bodies.

Send your message to us

High Quality Non Woven Geotextile Fabric - Polypropylene Construction Geotextile at Cheap Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords