High Quality FRP Pultrusion Profiles for Wind Turbine Blades

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000000 watt

- Supply Capability:

- 833 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Blades Wind Turbine Blades of High Quality

General Description about Our Wind Turbine Baldes:

Sinoma Wind Power Blade bases have been established in Funing of Jiangsu,Handan of Hebei Province, Pingxiang of Jiangxi Province, Jiuquan of Gansu, Xilingol of Inner Mongolia, Baicheng of Jilin Province, and Hinggan League of Inner Mongolia, with annual total production capacity reaching equivalent to 10GW.

Sourcing from natural wind keeping a sustainable world. Sinoma Blade is committed to building the most customers respect and employees, shareholders trust with the global competitiveness of the world’s first-class wind power blade enterprises.

Detailes about our Wind Turbine Blades:

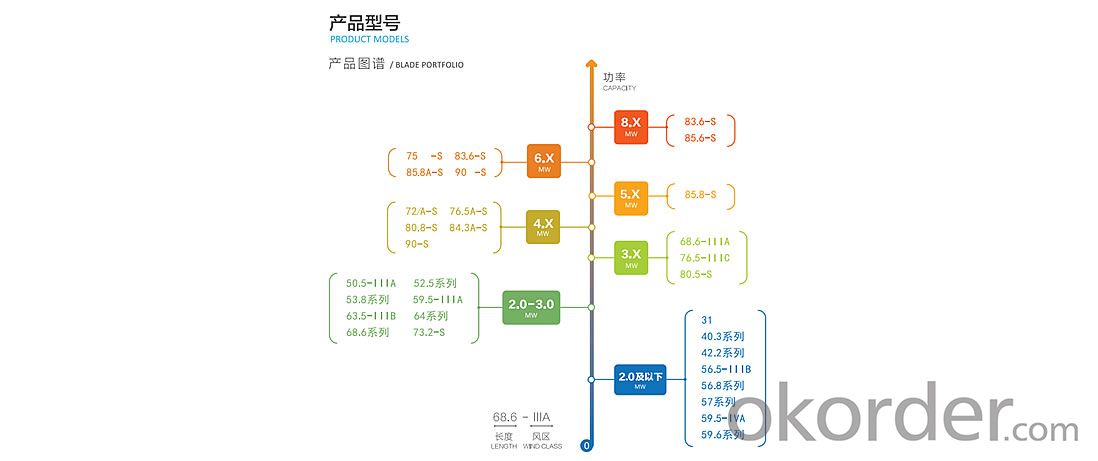

Our Blades has below type :

PROJECT REFERENCE:

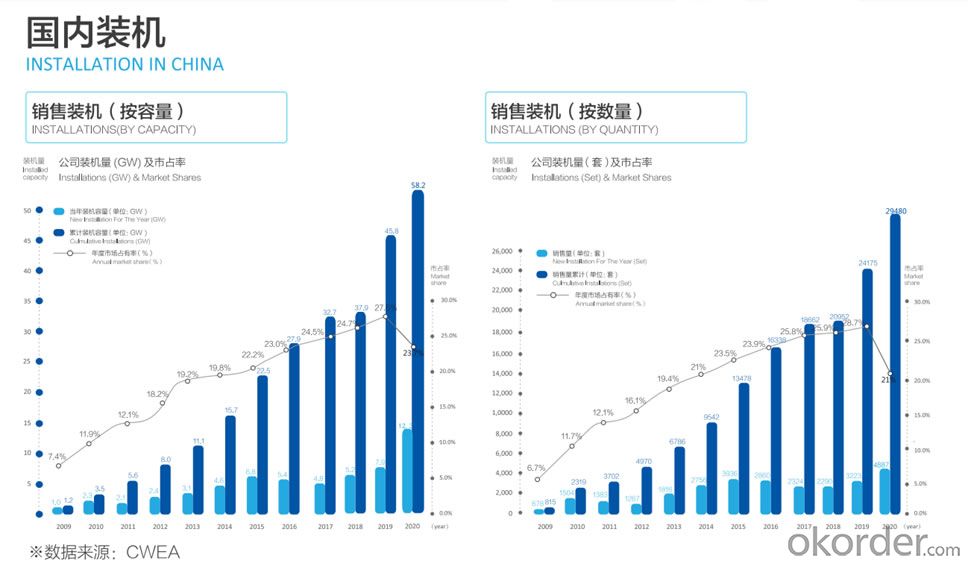

THE DOMESTIC MARKET:

THE GLOBAL INSTALLATION:

By end of June 2021, 30883 sets of blades (63580MW) are installed.

Including 1628 sets (4386.1MW) installed in 24 countries overseas.

- Q: Can FRP pultrusion profiles be used in the automotive industry?

- Yes, FRP pultrusion profiles can be used in the automotive industry. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. These profiles can be used for various automotive applications including body panels, structural components, and interior parts.

- Q: Are FRP pultrusion profiles resistant to high winds or hurricanes?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to high winds and hurricanes. FRP is a composite material that combines the strength of fiberglass with the durability of polymers. This results in a lightweight yet incredibly strong material that can withstand extreme weather conditions. FRP pultrusion profiles have been extensively tested and have proven to have excellent wind resistance properties. They have a high stiffness-to-weight ratio, allowing them to withstand the forces exerted by high winds without bending or breaking. Additionally, the inherent flexibility of FRP allows it to absorb and distribute the forces exerted by wind, reducing the risk of damage. In the case of hurricanes, FRP pultrusion profiles have demonstrated their ability to withstand the strong winds and flying debris associated with these severe weather events. They have been used in various applications such as building facades, bridges, and utility poles in hurricane-prone areas, with great success. Furthermore, FRP pultrusion profiles are corrosion-resistant, which is another advantage when it comes to withstanding high winds and hurricanes. Unlike traditional materials like steel or wood, FRP profiles do not rust or rot when exposed to moisture, making them even more suitable for these challenging weather conditions. Overall, due to their high strength, durability, flexibility, and corrosion resistance, FRP pultrusion profiles are an excellent choice for applications where resistance to high winds or hurricanes is required.

- Q: Are FRP pultrusion profiles resistant to impact from heavy machinery?

- Yes, FRP pultrusion profiles are highly resistant to impact from heavy machinery due to their inherent strength and durability. The strong composite materials used in their construction, such as fiberglass reinforced polymers, provide excellent impact resistance, making them a reliable choice for applications where heavy machinery might be involved.

- Q: Are FRP pultrusion profiles resistant to impact?

- Yes, FRP pultrusion profiles are generally resistant to impact. The combination of fibreglass reinforcement and resin matrix in FRP pultrusion profiles provides high strength and stiffness, making them less susceptible to damage from impact compared to other materials such as wood or metal. However, the impact resistance may vary depending on the specific design and composition of the FRP profile.

- Q: How do FRP pultrusion profiles compare to steel or aluminum profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages over steel or aluminum profiles. Firstly, FRP profiles are extremely lightweight, making them easier to handle and install. This is particularly beneficial in industries where weight reduction is crucial, such as aerospace or automotive applications. Another significant advantage of FRP pultrusion profiles is their exceptional corrosion resistance. Unlike steel or aluminum, FRP does not rust or corrode when exposed to moisture, chemicals, or harsh environmental conditions. This property makes FRP profiles ideal for applications in marine environments or chemical processing plants, where traditional materials would quickly deteriorate. In terms of strength, FRP pultrusion profiles can match or even surpass steel or aluminum profiles. The unique combination of reinforcing fibers and polymer resin in FRP provides excellent tensile and flexural strength. Additionally, FRP profiles have a high stiffness-to-weight ratio, meaning they can withstand heavy loads while remaining lightweight. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties. Unlike metal profiles, FRP does not conduct electricity, making it a safe choice for electrical applications where insulation is crucial. While steel or aluminum profiles may have their own advantages in certain applications, FRP pultrusion profiles often provide a more cost-effective solution due to their long lifespan and low maintenance requirements. FRP profiles are not susceptible to rust, corrosion, or degradation, minimizing the need for frequent repairs or replacements. Overall, FRP pultrusion profiles offer a compelling alternative to steel or aluminum profiles, providing lightweight, corrosion-resistant, strong, and electrically insulating solutions for various industries and applications.

- Q: Can FRP pultrusion profiles be used in infrastructure projects?

- Yes, FRP pultrusion profiles can be used in infrastructure projects. These profiles are lightweight, durable, and corrosion-resistant, making them ideal for applications in bridges, walkways, railings, and other structural components. They offer high strength-to-weight ratios and can be customized to meet specific project requirements. Additionally, FRP pultrusion profiles are non-conductive, making them suitable for electrical infrastructure projects.

- Q: Can FRP pultrusion profiles be used in the construction of highway guardrails?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of highway guardrails. FRP pultrusion profiles offer several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for highway guardrails. They have a high strength-to-weight ratio, which means they can provide the necessary structural support while being much lighter than traditional materials like steel. This makes transportation, installation, and maintenance easier and more cost-effective. Secondly, FRP pultrusion profiles are corrosion-resistant. Unlike steel, which can rust over time due to exposure to harsh weather conditions, FRP does not corrode. This makes FRP guardrails durable and long-lasting, reducing the need for frequent repairs or replacements. Additionally, FRP pultrusion profiles are non-conductive, meaning they do not conduct electricity. This is an important safety feature for highway guardrails, as it eliminates the risk of electrical shock in case of accidents involving power lines or lightning strikes. Furthermore, FRP pultrusion profiles can be manufactured in various shapes and sizes to meet the specific requirements of highway guardrails. They can be designed to have the necessary stiffness and impact resistance to withstand the forces exerted by vehicles during accidents or collisions. In summary, FRP pultrusion profiles are a suitable material for the construction of highway guardrails due to their lightweight, corrosion-resistant, non-conductive, and customizable properties. They offer a cost-effective and durable solution that can contribute to improving safety on highways.

- Q: Are FRP pultrusion profiles resistant to termites?

- FRP pultrusion profiles are typically immune to termites. Termites mainly consume materials that contain cellulose, such as wood. However, FRP pultrusion profiles, composed of resin and glass fibers, lack cellulose and are hence unappealing to termites. As a result, FRP pultrusion profiles offer an excellent substitute for conventional wooden profiles in situations that demand termite resistance, like building construction and outdoor structures. Furthermore, FRP profiles demonstrate resistance against decay, corrosion, and various environmental elements, rendering them a robust and enduring material option.

- Q: Are FRP pultrusion profiles UV resistant?

- FRP pultrusion profiles are known for their UV resistance. This is because manufacturers use a combination of polymer resin and reinforced fibers, like fiberglass, to create these profiles. These materials naturally possess UV resistant properties, which means that FRP pultrusion profiles can withstand prolonged exposure to sunlight and ultraviolet radiation without getting damaged. For outdoor applications, such as in construction, infrastructure, and marine industries, UV resistance is an important characteristic. However, it's worth noting that the level of UV resistance can vary depending on the specific resin and fiber composition used in the manufacturing process. To get precise information about the UV resistance of FRP pultrusion profiles for a specific application, it's advisable to consult the manufacturer or supplier.

- Q: Can FRP pultrusion profiles be used for structural applications?

- Yes, FRP pultrusion profiles can be used for structural applications. They are commonly utilized in various industries such as construction, automotive, aerospace, and marine. FRP pultrusion profiles offer high strength-to-weight ratio, excellent corrosion resistance, and durability, making them suitable for structural components like beams, columns, and trusses. Additionally, they can be designed to meet specific load requirements and offer design flexibility.

Send your message to us

High Quality FRP Pultrusion Profiles for Wind Turbine Blades

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000000 watt

- Supply Capability:

- 833 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords