FRP Bolt Glass reinforced plastic anchor rod

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Bolt support in coal mines in recent years, railway, highway, water conservancy and urban construction engineering project, at the same time, the rapid development in the glass fiber reinforced plastic (GRP) anchor applied correspondingly, GRP anchor of safety and operability are far more than the metal bolt now used by coal mining, and is gradually replacing the traditional metal bolt, is the new alternative metal bolt supporting materials. Its advantages:

1, high strength, easy cutting rod body: the tensile strength of glass fiber reinforced plastic anchor rod is better than that of ordinary steel, higher than 20% of the steel bar, the same specification and good fatigue resistance performance, light weight, only for the same volume of steel 1/4. Its material is a composite material, easy cutting, can protect the coal winning machine cutting head;

2, safety performance is good, explosion-proof anti-static: thermal conductivity, conductive, flame retardant, antistatic, collision won't produce sparks, through the formula change and metal for tunnel safety construction is very good, especially suitable for gas concentration area;

3, Gao Jiangnai corrosion, high bearing capacity, tensile resistance is strong, the diameter of the rod body strength is better than that of rebar bolts, as a support for a long time, can resist erosion of chloride ions and low PH solution, especially the resistance to corrosion of carbon compounds and chlorine compounds is better.

4, material binding force strong: closer to the cement thermal expansion coefficient compared with steel, so the rod body with concrete grip of stronger;

Light 5, can design sex is strong, easy to operate, stable modulus of elasticity, thermal stress under the size stability, heat bending shape can be arbitrary shape, and weight is only 1/4 of coequal norms metal bolt, can be used in tight Spaces such as tunnels and mines is convenient, make it easier for the construction, reduce labor intensity;

6, construction is convenient, can produce all kinds of different cross section according to the requirement of the user and the length of the standard and non-standard, non-metallic drawstring tie available at the scene, the operation is simple.

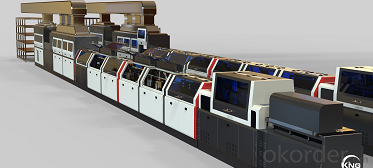

Glass reinforced plastic anchor rod production equipment, our company is using the company independent research and development, after more than 10 years of market recognition, production research and development department improve MYC - 1200 pultrusion equipment, with completely independent intellectual property rights, more than 20 supporting patent technology, is a domestic initiative.

So far, our company has formed glass reinforced plastic anchor rod of raw materials, production equipment, glass fiber reinforced plastic anchor rod products production and sales of the whole industry chain, pultrusion technology, production, processing and application of full thread glass reinforced plastic anchor rod, the glass fiber content as high as 80%, at the same time because of pultrusion technology of prestressed effect, can greatly improve the strength of glass fiber reinforced plastic anchor rod body, tensile strength can be big, to ultra high strength bolt corresponding technical indicators. And can be installed directly nut, because the rod surface area significantly increase can significantly increase the anchorage rod body strength and tensile strength; Tray, nut supporting with tray, nut of invention patent.

- Q: Can FRP pultrusion profiles be used in modular construction?

- Certainly, FRP (Fiber Reinforced Polymer) pultrusion profiles are a viable option for integration into modular construction. These profiles possess advantageous qualities, including a lightweight composition, exceptional strength, resistance to corrosion, and superb thermal and electrical insulating properties. These attributes make them an ideal choice for implementation in modular construction, where the focus is on prefabrication, transportation, and swift assembly. The utilization of FRP pultrusion profiles within modular construction yields numerous benefits. Firstly, their lightweight nature facilitates easy handling and transport, which consequently reduces logistical costs and effort. Secondly, their high strength-to-weight ratio ensures structural integrity without adding unnecessary weight to the modular components. This is especially advantageous in scenarios where weight reduction is critical, such as rooftop installations or areas with limited load-bearing capacity. Moreover, the corrosion resistance of FRP profiles eliminates the necessity for regular maintenance and enhances the longevity of the modular construction. This proves particularly advantageous in challenging environments, like coastal regions or chemical processing facilities, where traditional construction materials like steel may rapidly deteriorate. Furthermore, FRP pultrusion profiles can be easily tailored to fulfill specific design requirements. They can be manufactured in diverse shapes, sizes, and colors, granting flexibility in modular construction design. Additionally, these profiles can be seamlessly integrated with other construction materials, such as concrete or wood, ensuring compatibility with existing modular systems. To summarize, the lightweight nature, high strength, corrosion resistance, and customization capabilities of FRP pultrusion profiles make them highly suitable for modular construction. Their implementation in this field improves efficiency, reduces costs, and enhances the overall performance and durability of modular buildings and structures.

- Q: Can FRP pultrusion profiles be used in telecommunications applications?

- Telecommunications applications can utilize FRP pultrusion profiles, which offer a range of advantages that render them suitable for such infrastructure. To begin with, these profiles possess the desirable combination of being lightweight and strong, making them an excellent choice for supporting antennas, cable trays, and equipment racks. Their high strength-to-weight ratio enables easier installation and transportation while providing the necessary structural support. Moreover, FRP pultrusion profiles display corrosion resistance, a crucial characteristic for telecommunications applications. Given the exposure of telecommunications infrastructure to harsh environments like moisture, chemicals, and extreme temperatures, FRP's non-corrosive properties guarantee long-term durability and reliability, distinguishing it from traditional materials such as steel or wood. Additionally, FRP pultrusion profiles offer electrical insulation properties, which are vital in telecommunications applications. By not conducting electricity, they ensure safety in areas where electrical equipment is present. This feature prevents electrical interference and preserves the integrity of the telecommunications system. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, as they can be manufactured in various shapes and sizes. This flexibility allows for the efficient design of telecommunications infrastructure, making FRP pultrusion profiles suitable for a wide range of applications within the industry. In conclusion, FRP pultrusion profiles prove to be well-suited for telecommunications applications due to their lightweight yet strong nature, corrosion resistance, electrical insulation properties, and customization possibilities. These attributes guarantee their reliability in supporting and protecting telecommunications infrastructure.

- Q: The manufacturing process of FRP products?

- Each technique has its own characteristics. Production enterprises determine the process method in the selection, according to the basic situation of the enterprise and the production of products, such as mass production and product quality requirements, as well as the technical basis for enterprise capital and production factors such as comprehensive consideration.

- Q: Can not use glass steel support column, the main support for the door

- 1, glass steel toughness and carrying impact performance is strong, but the rigidity is relatively poor, that is, tensile, impact resistance is better, compressive performance is poor, so it is not suitable for props and other components.2, toughened glass is completely transparent, visual art, and the vertical stiffness is very large, excellent compressive strength, can be customized according to the needs of the processing of different thickness, if used to support the weight is not a big door can, but need to have the steel frame (outsourcing stainless steel).

- Q: Can FRP pultrusion profiles be used in the aerospace industry?

- FRP pultrusion profiles are suitable for use in the aerospace industry. They possess several advantages that make them ideal for aerospace applications. Firstly, their high strength-to-weight ratios are crucial in the aerospace industry, where weight reduction is a top priority. This lightweight quality contributes to fuel efficiency and increased payload capacity. Secondly, FRP profiles have excellent corrosion resistance, making them perfect for aerospace applications that involve exposure to harsh environments like high altitude, extreme temperatures, and moisture. This resistance ensures the durability and longevity of the components, reducing maintenance and replacement costs. Additionally, FRP materials can be customized to meet specific design requirements, allowing engineers to easily create complex shapes and structures. This flexibility in design leads to enhanced performance and functionality in aerospace applications. Moreover, FRP pultrusion profiles exhibit exceptional fatigue resistance, enabling them to withstand the cyclic loading and stress cycles commonly encountered in aerospace operations. This characteristic ensures the reliability and safety of the components, which is paramount in the aerospace industry. Furthermore, FRP materials offer electrical insulation properties, which can be advantageous in aerospace applications where controlling or minimizing electrical conductivity is necessary. This insulation capability contributes to the overall safety and functionality of the components. In conclusion, FRP pultrusion profiles are a viable and attractive choice for various aerospace applications, including aircraft structures, interior components, radomes, and others. Their high strength-to-weight ratios, corrosion resistance, flexibility in design, fatigue resistance, and electrical insulation properties make them a suitable option for the aerospace industry.

- Q: Can FRP pultrusion profiles be used in railway applications?

- Yes, FRP pultrusion profiles can be used in railway applications. They are lightweight, corrosion-resistant, and have high strength-to-weight ratio, making them suitable for various structural and non-structural components in railway systems such as platforms, walkways, handrails, and cable management systems. Additionally, FRP profiles offer excellent electrical insulation properties and can withstand extreme weather conditions, making them a reliable choice for railway applications.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of antenna masts?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of antenna masts. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent electrical insulation properties. These characteristics make them ideal for antenna mast construction, as they can withstand various environmental conditions and provide reliable support for antennas.

- Q: Can FRP pultrusion profiles be used in the aerospace and aviation industry?

- Indeed, the aerospace and aviation industry can utilize FRP pultrusion profiles. These profiles offer an exceptional ratio of strength to weight, corrosion resistance, and flexibility in design, making them suitable for a wide range of applications in this field. A primary advantage of FRP pultrusion profiles is their ability to provide high structural integrity while maintaining a low weight. This is crucial in aerospace and aviation, where reducing weight is a top priority. By being lightweight, FRP profiles can contribute to fuel efficiency, improved performance, and increased payload capacity. Moreover, FRP pultrusion profiles display excellent resistance to corrosion, including chemicals, moisture, and UV radiation. This makes them highly suitable for use in aircraft and aerospace systems that often face harsh environmental conditions. Unlike traditional metallic materials, FRP profiles can withstand corrosive agents and maintain their structural integrity for extended periods. This reduces maintenance needs and enhances the durability of aircraft components. Additionally, the design flexibility of FRP pultrusion profiles allows engineers to create complex shapes and geometries, enabling customization to meet specific requirements. This design versatility opens up opportunities for innovative solutions in aerospace and aviation applications, such as structural components, aircraft interiors, radomes, fairings, and more. It is important to note that FRP pultrusion profiles have already been successfully employed in the aerospace and aviation industry for various applications, including wing spars, stabilizers, galleys, interior panels, and cargo containers. Their proven track record demonstrates their reliability and performance in demanding environments. In conclusion, FRP pultrusion profiles are highly suitable for use in the aerospace and aviation industry due to their high strength-to-weight ratio, corrosion resistance, and design flexibility. Their utilization can contribute to lighter, more efficient, and durable aircraft components, making them a viable choice for various applications in this sector.

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- Yes, FRP pultrusion profiles are highly resistant to oil and grease due to the inherent properties of the fiberglass reinforcement used in their construction. The composite material offers excellent chemical resistance, making it suitable for applications where exposure to oil and grease is expected.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical reactors?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of chemical reactors. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent resistance to corrosion, high strength-to-weight ratio, and dimensional stability, making them ideal for use in chemical reactors. Additionally, FRP materials can withstand a wide range of chemical environments and temperatures, making them a reliable choice for this application.

Send your message to us

FRP Bolt Glass reinforced plastic anchor rod

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords