High-Quality Electric Arc Furnace Graphite Electrodes with Nipple

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite Electrode

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to

700mm. Our products own the following characteristics: low electric resistance, good electric and

thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

Product Applications:

It is used for the electric arc furnace steel making. (About 70-80% graphite electrode is used for steel making).

It is used for the submerged arc furnace, including melting iron alloy, pure silicon, yellow

phosphorus,matte, calcium carbide and so on.

It is used for the resistance furnace, such as the graphite making, melting glass, silicon carbide

making and so on.

Product Advantages:

28 drums counter-flow calcining furnace

Auto-control dosing system

Germany Enrich kneading system

3500MT vertical tamping&horizontal extruding press

Auto-comtrol ring backing furnace

Germany Feist-incon 2nd Baking Kiln

High pressure imprgnation system

Acheson high power DC graphitizing furnace

Japan Nachi NC electrode machining line

America lngersoll NC electrode machine line

Japan Nachi NC nipple machining line

Carbon fiber production line

Main Product Features:

Good electrical conductivity

High resistance to thermal shock

High mechanical strength

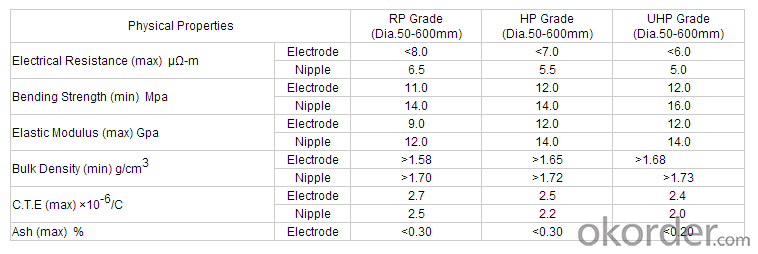

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

6. What standards do we have?

Our products meet the standards, such as ASTM, ASME, AMS, DIN, JIS etc.

The third party testing is all available for us.

Product Picture

- Q: What is the difference between pyridine type nitrogen and graphite type nitrogen?

- The fine structure graphite is the raw material used in the production of graphite electrode. The particle size is relatively small, generally below 0.5.

- Q: The reason why graphite is used as electrode

- Graphite is good in plasticity and easier to be machined preciselyGraphite material has the advantages of high processing accuracy and good surface effect, especially in the processing of precise, complex, thin-walled and Gao Ying material mold cavity. Because the cutting resistance of graphite is only 1/5 of copper material, it is easier to do manual grinding and polishing on the operation. There is no burr after graphite processing, and it is easier to realize automatic production. Complex geometric modeling can be realized.

- Q: What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The high purity graphite component is put into the furnace, and nitrogen and methane are produced under vacuum high temperature. Then graphite is shown to produce 10% coating.

- Q: The original battery is not necessary to form the electrode potential? Why can we use graphite as electrode only? No potential difference.

- Indeed, the original battery electrode potential using two different electrodes, produce potential difference, so that the electron flow generated current. Graphite is used as an electrode because of its excellent electrical conductivity and stability

- Q: Which department in the steel plant needs graphite in large quantities?

- For steel and iron alloys, graphite electrodes are used, when powerful currents pass through electrodes into the melting zone of the electric furnace to produce an arcThe electric energy is converted into heat energy, and the temperature is increased to about 2000 degrees, so as to achieve the purpose of smelting or reaction. In addition, the electrolytic goldWhen the magnesium, aluminium and sodium are used, the anode of the electrolytic cell is also made of graphite electrode. The resistance furnace for carborundum is also made of graphite electrode as the burnerConductive material.

- Q: How long is the graphite electrode machining cycle?

- Industrial graphite is hard and brittle, and the tool is worn more seriously during machining. It is generally recommended to use carbide or diamond coated cutting tools. When the graphite is rough, the cutter can be directly worked on the workpiece. When it is finished, it is necessary to use light knife to walk quickly to avoid the occurrence of chipping and chipping

- Q: What kind of asphalt is better for natural graphite coating?

- Graphite anode is mainly made of petroleum coke as raw material and coal pitch as binder. It is made by calcination, batching, kneading, pressing, roasting, impregnating, graphitization and machining. Conductive anode used for electrolysis equipment in electrochemical industry. Including: (1) anode plate for various chemical industries. (2) all kinds of anode rods.

- Q: MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- The three is difficult cold start, is sparking difficult, not easy car, and finally the combustion chamber carbon Yan will cause a heavy cylinder knock, low speed and acceleration noise, causing damage to the piston and crankshaft, causing the engine temperature which can seriously affect the automobile safety. Emission standards exceeded, not only through the annual inspection, but also directly aggravate the pollution of the environment

- Q: 800KVA and 12500 EAF transformer data graphite electrode furnace.

- Graphite project: Project Description: steel furnace and iron smelting furnace, ferrosilicon smelting, electrolytic aluminum and so on, all use large surface graphite electrode.

- Q: What does graphite electrode GSK mean?

- Graphite board material is GSK, GSK refers to model specifications

Send your message to us

High-Quality Electric Arc Furnace Graphite Electrodes with Nipple

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords