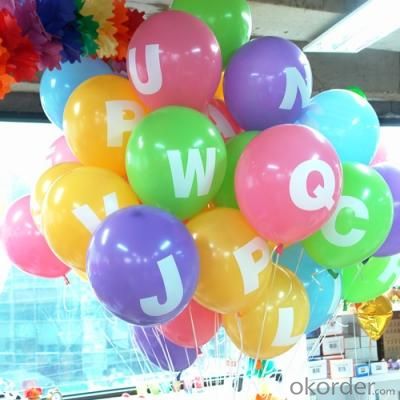

High quality custom printed led ballon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Custom printed artwork balloons,Free shipping to worldwide

Material | 100% Natural Latex SGS,En71 |

Use | Advertising,promotion,party,event,wedding |

Festival | all holiday |

| skype: | wlballoon |

Certificate | EN71 part1,2,3 ASTM F963,CPSIA(H.R.4040) ,Nitrosamine-free |

Colors | Red, orange, yellow, pink, white, dark green,light green,blue,light blue, black,purple,rose |

Logo/artwork | your design or we help design |

Shape | Round or heart shape |

packing | 100pcs/polybag,50bags/ctn |

delivery time | 2-10 days delivery time according to order quantity Custom printed balloons,Free shipping to worldwide Material100% Natural Latex SGS,En71UseAdvertising,promotion,party,eventFestivalall holidayskype:wlballoonCertificateEN71 part1,2,3 ASTM F963,CPSIA(H.R.4040) ,Nitrosamine-freeColorsRed, orange, yellow, pink, white, dark green,light green,blue,light blue, black,purple,roseLogo/artworkyour design or we help designShapeRound or heart shapepacking100pcs/polybag,50bags/ctndelivery time2-10 days delivery time according to order quantity |

light up balloons

- Q: What are the differences in the properties of neoprene models?

- Different types of applications are different:CR122 chloroprene rubber: belt, conveyor belt, wire and cable, oil resistant rubber sheet, oil hose, sealing materials and other rubber products.CR232 chloroprene rubber: cable sheath, oil resistant hose, rubber seals, adhesives and so on.CR2441 2442 chloroprene: a raw material used in adhesives for bonding metals, wood, rubber, leather and other materials.CR321 322 type chloroprene rubber cables, plywood, ordinary and hose, oil resistant rubber boots, air duct, cloth, tent cloth, conveyor belt, conveyor belt, rubber seals, agricultural capsule cushion, lifeboat etc..Used as toughening agent for modified acrylate fast structural adhesive (SGA).

- Q: How long is the warranty period for EPDM?

- (1). Rubber molding, after pressing, the elastic body is within the cohesion can not be eliminated, the molding die, often have a very unstable contraction (rubber shrinkage due to rubber vary), required after a period of time, and can be stable. Therefore, when a rubber product design at the beginning, regardless of formula or mold, it is necessary to carefully calculate the coordination, if not, it is easy to produce product size instability, resulting in lower quality products.(2). A rubber elastic body of thermosetting plastic hot melt, belongs to the hot cold setting. Rubber due to different types of sulfide species, its molding and curing temperature range is also a considerable gap, and even can be affected by climate change, indoor temperature and humidity affected. Therefore, the production conditions of rubber products need to be adjusted at any time. If not, the quality of the products may be different.(3) rubber products are made of rubber raw materials and used as raw materials made from the rubber compound of the mixer, and the formula is designed according to the characteristics of the required rubber products, and the required hardness of the products is determined. The product is made and molded by rubber flat vulcanizing machine. Finally, the product is processed by flying edge, and the surface of the product is treated smoothly without burrs.(4). Aging test of rubber products aging test belongs to the category of rubber aging refers to rubber and products in the processing, storage and use of the process, due to the comprehensive effect of internal and external factors caused by the performance of the structure change, then the loss of use value phenomenon. They are crazing, sticking, hardening, softening, powdering, discoloration, mildew, etc..

- Q: What are the uses of rubber oil?

- The effect of rubber regeneration: thick pine tar smoke containing regeneration agent of other small molecules, which can penetrate into the intermediate node containing uniform molecular sulfur rubber, the swelling, reticular structure relaxation, increased permeability and oxygen distance between molecular chains, also can be used as acceptor free the base, inhibiting gelation effect, also helps to accelerate the diffusion of the activator rubber matrix regeneration process, and can improve the regeneration of plastic viscosity and plasticity, and less pollution, good processing performance.

- Q: How to maintain and store the rubber material?

- When storing, matters needing attention are:(1) should be stored in a ventilated, dry environment, the relative humidity of the air is 50% ~ 80%.(2) should be stored in non corrosive media, and away from the heat source, the temperature is about 5 degrees Celsius conditions(3) packing should be kept as far as possible without box stacking

- Q: Comparison of physical properties of HNBR rubber material with other rubber materials

- Hydrogenated nitrile rubber, referred to as "HNBR" or "H-NBR". It is a new variety of nitrile rubber (NBR).

- Q: How can rubber products prevent fading?

- That is to add UV absorbers, white, then add more titanium dioxide, there is no good way, as well as your choice of pigment, as far as possible difficult to fade, such as inorganic pigments.

- Q: What is rubber leather?

- The general rubber has good comprehensive properties and is widely used. The main contents are as follows: natural rubber. From the latex of the Hevea tree, the basic chemical composition is cis polyisoprene. Good elasticity, high strength and good comprehensive performance. Isoprene rubber. The full name is cis -1, 4- polyisoprene rubber, a high CIS synthetic rubber made from isoprene, because of its structure and properties similar to natural rubber, it is also called synthetic natural rubber. Styrene butadiene rubber. Referred to as SBR, made by copolymerization of butadiene and styrene. According to the production method, emulsion polymerization, styrene butadiene rubber and solution polymerized styrene butadiene rubber are divided into emulsion polymerization. Its comprehensive properties and chemical stability are good. The br. The full name is cis -1, 4- polybutadiene rubber, referred to as BR, made from butadiene polymerization. And the other than universal rubber, vulcanized butadiene rubber cold resistance, abrasion resistance and excellent elasticity, dynamic load, less heat, good aging resistance, easy and natural rubber, chloroprene rubber, nitrile rubber and etc..

- Q: Is polyurethane and polyurethane rubber one thing?

- Polyurethane is a very special polymer, it is composed of hard and soft segments, the hard part of Tg is very low, with plastic characteristics, soft section of Tg is higher than room temperature, a lot of rubber characteristics. In the process of synthesis of polyurethane, by controlling polymerization, the proportion of hard segment and soft segment of polymer can be adjusted, so that polyurethane can be expressed as plastic or rubber.Rubber shoes, excluding plastic shoes, should not be included in general sense. Common sense says in rubber overshoes, it is the waterproof shoe that rains commonly, army shoe, plastic shoe has slipper commonly.

- Q: What kind of rubber does TPE belong to?

- Thermoplastic elastomer TPE (Thermoplastic, Elastomer) is a kind of material with high elasticity, high strength, high resilience, and has the characteristics of injection molding. Nontoxic security, wide range of hardness, with excellent color, soft touch, weather resistance, fatigue resistance and temperature resistance, excellent processing performance, without curing, can reduce the cost of recycling, can be two times of injection molding, and PP, PE, PC, PS, ABS and other base materials the adhesive, can also be a separate molding.

- Q: PVC conveyor belts and rubber belts differ from each other in their respective advantages

- Rubber belts are widely used in conveying equipment, but do you know that proper vulcanization of rubber can maintain high elasticity of rubber and make rubber of a certain strength?. At the same time, in order to increase product hardness, strength, wear resistance and tear resistance, while adding inert filler in the process (such as Zinc Oxide, clay, chalk and barite etc.) and reinforcing filler (such as carbon black), which helps to improve the quality of the conveyor belt.

Send your message to us

High quality custom printed led ballon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords