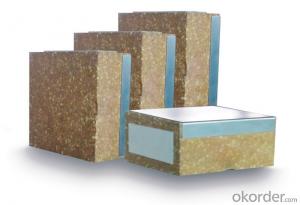

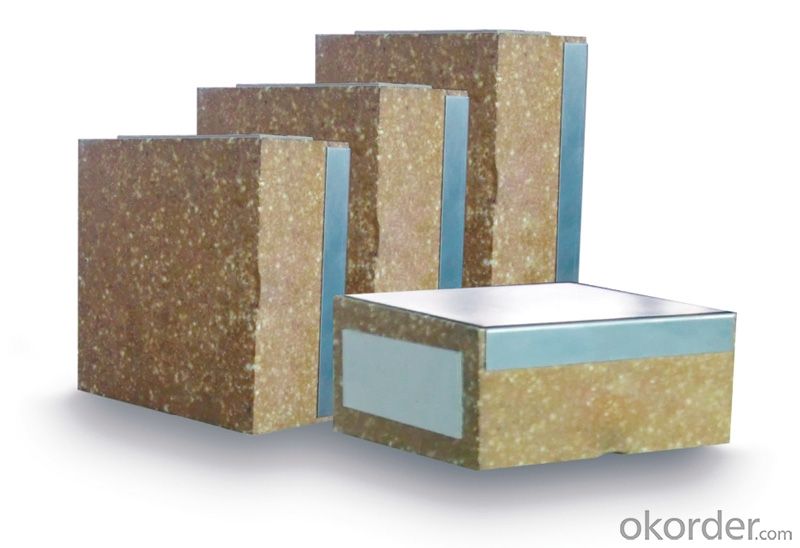

High Quality Corundum Magnesia Alumina Spinel Brick for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | wooden pallets |

| Delivery Detail: | 40 days after signing the contract |

Brief Introduction of Our Company

DASHIQIAO BAODING REFRACTORY CO.,LTD was founded in 2003 with a registered capital of 10 million yuan, covering an area of 20,000 square meters,situated in Dashiqiao city, Liaoning Province which is famous for rich resource of magnesite and is conveniently located near Shenyang-Dalian Highway, 200 kms away from Dalian Port and only 60 kms away from Bayuquan Port. Our company has been fully carrying out ISO9001:2008 Standard. If you are interested in any of our products, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: Application of electric high temperature regulating valve?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay. Brick is siliceous products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste. The silica acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high, close to the fire, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. The brick is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly used in glass furnace and coke oven silica brick for two categories. Clay brick with refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used in refractory clay brick clay as main raw material is called common clay brick that made pyrojewel clinker as the main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay bricks are divided into several grades according to the physical and chemical indexes. The price difference between the ordinary clay bricks and the low porosity clay bricks is great.

- Q: How much is a thermal brick?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: What material is used in an iron smelting furnace?

- Often used insulation refractories are diatomite products, asbestos products, insulation panels and so on.

- Q: What's the jade stove for?

- Is it a furnace made of corundum or a furnace for smelting corundum?Corundum brick stove is commonly used as a refractory material sintering furnace, can be fired refractoriness in refractories, below 1700 degrees such as brick, corundum brick, brick, alumina hollow ball and so on

- Q: What equipment is used for producing diamond blanks? How much is the investment?

- You'll have to invest about about one million if you want an electric furnace. A power distribution room is easiest to approach one hundred thousand. Electric furnaces, power distribution cabinets and transformers must be around one hundred and ten thousand.

- Q: Expansion ratio of lightweight corundum refractory bricks

- Now with the production of lightweight foam corundum brick, basically still meters with molding casting, moulding after together with die in the drying room drying in 60~70 C 4 days of release, then the appropriate drying, finally after 1300 and 1550 C firing, the total burning time: 50~60h. Light corundum brick after firing is usually not the size and shape of accurate, so that products after the kiln to mechanical or manual cutting, can be made into a density of 0.8 - 1.3g/cm3, 4MPa compressive strength and porosity, the thermal conductivity of 70%~80% 0.17W/ (M - K), light-weight corundum brick use temperature of 1500~1700 DEG C.

- Q: What is the difference between corundum and high alumina?

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: Is liquid phosphoric acid two aluminum hydrogen flammable?

- Liquid phosphoric acid two hydrogen aluminum features: easy mixing, molding, especially suitable for field construction, so liquid phosphoric acid two hydrogen aluminum is not flammable

- Q: What are the refractory materials?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions.

- Q: What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- The expansion curves of fused cast AZS brick at 1000 DEG C near a crystal anomaly, its internal changes of ZrO2 crystal are reversible, with large volume change, therefore, products containing ZrO2, should not be used in the temperature of 1000 DEG C, often have sharp fluctuations in the position. When baking the kiln, the temperature can not be too large at 900~1150 degrees centigrade. Generally, the temperature can not exceed 15 degrees /h, and the temperature should be raised steadily. Some parts to prevent the cold, with other brick protection, to prevent explosion.

Send your message to us

High Quality Corundum Magnesia Alumina Spinel Brick for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords