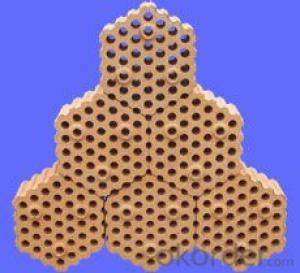

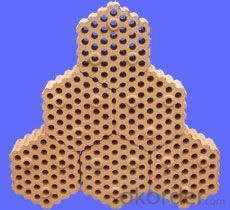

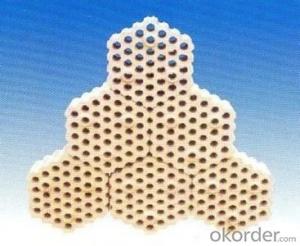

Corundum Clay Checker Brick 37 CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

checker brick is one new replaced production of the refractory balls, used in the hot blast heater kiln, to hold the tempreture.

Packaging & Delivery

| Packaging Detail: | wooden pallet with paper between each brick layer, wrapped with thick paper and PVC outside. |

| Delivery Detail: | one month after recevin the advance paymet |

| CHN LPBG-96 | CHN LBG-96 | BRD | JP | USA | UK | |

| SiO2 % | 97.6 | 96.54 | 95.9 | 98.5 | 95.64 | 96.18 |

| Fe2O3 % | 0.35 | 0.67 | 0.48 | 0.9 | 0.71 | 0.52 |

| % | 0.35 | 0.41 | 0.54 | 0.64 | 0.39 | |

| g/cm3 | 2.33 | 2.33 | 2.32 | 2.33 | 2.32 | 2.33 |

| % | 17 | 18 | 21.7 | 20 | 20.3 | 22 |

| Mpa | 45 | 38 | 32 | 35.6 | 56.8 | |

| 0.2Mpa℃ | 1690 | 1680 | 1680 | 1675 | 1690 | 1680 |

| 1450℃*2h% | +0.2 | +0.1 | +0.19 | |||

| % | 55 | 35~40 | 55 | |||

| % | 2 | 0 | 3~5 |

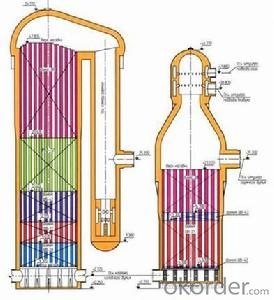

Checker brick is one refractory production, used in the hot blast furnance, to hold the tempreture inside of the furnance.Our company can design and manufacture hot blast furnance, according to the conditions of the steel mill factories.About the checker brick, we can manafacture and supply the clay checker brick/mullite checker brick/high alumina checker brick/ silicon checker brick.Differen materias should be used on different levels of the furnance. Clay checker bricks shoud be used on the bottom, cause the bottom tempreture of the furnance is the lowest. And then with the height higher , the material should be changed into mullite,high alumina,silicon.

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- In addition to AZS33# and AZS same co crystallization in vitro, 36#AZS due to the increase of chain like zirconia brick more crystals, while the glass phase content is low, so 36# AZS corrosion resistance has been further enhanced, so is suitable for the rapid flow of molten glass or high temperature region.AZS36 s is an excellent product in the AZS series. It has high resistance to glass liquid erosion and low pollution. It is usually used in the key parts of the glass furnace, such as the pool wall near the hot spot.

- Q: How much is a thermal brick?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: How much is a refractory brick?

- This question is too general, refractory bricks according to the use of the environment and industry, there are a variety of materials, a variety of specifications, prices vary greatly.

- Q: What are the advantages of refractories?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: What refractory materials are used in industrial furnaces?

- The working conditions of industrial furnaces should first be investigated thoroughly, and the primary and non essential factors affecting the construction of furnace materials shall be analyzed. Focus on thinking, the temperature change condition, temperature bump slag properties, furnace atmosphere, heat insulation, impact wear and other special requirements, to ensure the quality of the life and product.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- The sinter plate dust collector is also called plastic plate dust collector. The utility model has the advantages that the utility model can adapt to various complicated working conditions, the dust removal rate is 99.99%, the utility model has the advantages of long service life, stable operation, high temperature resistance, and the utility model is a leading dedusting equipment in china.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- Refractory brick is non-metallic materials can be classified according to a kind of inorganic material, high aluminum brick, clay brick, magnesia brick, corundum brick, mullite bricks, silicon carbide materials such as brick, high alumina brick is used as a relatively wide range of products in accordance with the refractory brick high alumina refractory materials by high aluminum brick is generally divided into Al2O3 content three: I - II - >75% Al2O3 content; the content of Al2O3 is 60 ~ 75%; III - Al2O3 content from 48 to 60%.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: What kind of rock is corundum produced?

- Aluminum oxide (Al2O3) mineral. Due to Mohs hardness of up to 9, mainly used as high-grade abrasives. The crystal belongs to the three party system, a dolioform six square column, some are needle or plate. Aggregates are massive or columnar. Usually white, gray, yellow and other colors. If a small amount of Cr3+ is red, a ruby is called;

- Q: What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- Casting, casting mouth often appear shrinkage, brick porosity more, the density is lower, so in the brick wall of glass melting, the shrinkage in the kiln direction, if the nozzle outward, when the brick to erosion is very thin, can cause leakage of liquid glass accident. When the flame space is used in the upper part of the bath furnace, the service life is long, and the glass liquid problem can not happen, so the casting mouth is used outwards, and the service life is prolonged.

Send your message to us

Corundum Clay Checker Brick 37 CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords