High Quality Carton palletizing machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Carton palletizing machine made in China

Description of High Quality Carton palletizing machine made in China

Robotic palletizers are suitable for chemical, beverage, food, beer, plastics, air conditioning and other manufacturing companies to box and palletize, canned, boxed, bottled, and other shapes of finished products. The structure is very simple, easy to maintain and repair; the main components of fewer parts, fewer parts, so the maintenance costs are very low; robot hand palletizing machine can be set in a narrow space, you can effectively use; all control can be operated on the control cabinet screen , the operation is very simple. Can work all day, equipped with robots can replace the workload of many workers.

Main Features of High Quality Carton palletizing machine made in China

1. The robot has powerful computing functions and high-precision operations, enabling rapid packing, palletizing and demolition work.

2. In the production line, the robot pallets for packing, palletizing, and demolition work can be flexibly laid out. It is ideal for palletizing at the end of the production line to palletize two or more lines at the same time.

3. The servo motors, programmable controllers, and frequency conversion speed controllers use top quality products to ensure the reliability and long life of the system hardware.

4. High-quality hardware is combined with specialized control software designed by experts to achieve a highly automated system. Perfect safety interlock mechanism can provide protection for equipment and operators.

5. Our superior technology, stable and reliable products and perfect services improve the level of factory automation.

Specifications of High Quality Carton palletizing machine made in China

| Assignment style | Horizontal gripper type |

| Productivity | 45 boxes/minute |

| Processing products | Boxes, containers, cans, etc. |

| Product conveyor belt height | 850mm |

| Tray conveyor height | 650mm |

| Tray size | 140MMH(approx) |

| Stacking method | According to user requirements |

| Pallet stacker | 15 trays as a benchmark |

| Power supply | 11Kw |

| Equipment weight | 5500kg |

| Equipment size | L8400 mm x W4700mm x H3700mm |

Applications of High Quality Carton palletizing machine made in China

Robotic palletizers are suitable for chemical, beverage, food, beer, plastics, air conditioning and other manufacturing companies to box and palletize, canned, boxed, bottled, and other shapes of finished products.

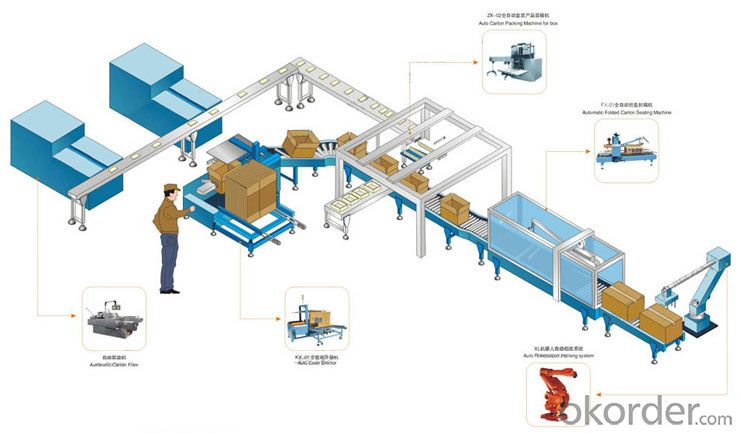

Robotic palletizers can be integrated in any production line to provide intelligent, robotized, and networked production sites, palletizing logistics for a wide variety of jobs in the beer, beverage and food industries. They are widely used in cartons, pharmaceuticals, chemicals, and beverages. , food, beer, plastics, air conditioners, plastic boxes, bottles, bags, drums, film bags and filling products. Supporting three-in-one filling lines, etc., for all types of bottles and bags for palletizing. The automatic operation of the palletizing machine is divided into steps such as automatic feeding, transfer, sorting, stacking, shifting, stacking, feeding, down stacking, and exporting.

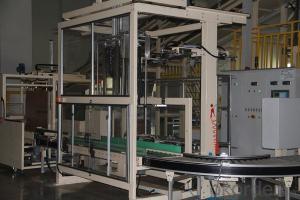

Images of High Quality Carton palletizing machine made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q: What are the main functions of packaging machinery?

- The main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging

- Q: Bread packing machine Product features

- Product features1. double frequency control, bag length is cut, no need to adjust the empty walk, one step in place, save time and save the film.2. man-machine interface, parameter setting is convenient and quick.3. fault diagnosis function, clear failure display.

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- China's packaging machinery and equipment manufacturing enterprises should seize this opportunity.The overall upgrading of packaging machinery equipment is the general trend of the development of packaging machinery in China and the world. The main features of the renewal is: a large number of transplanted with civilian and military industries all modern high precision technology and electronic technology, microelectronic technology, edge technology, fuzzy technology, accelerate the further improve the reliability, safety, no work of the level of automation of packaging machinery and equipment and production line. Intelligence will move into the field of packaging machinery, equipment and production lines.

- Q: What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- This situation is best to find after sale processing, you have difficulty adjusting normal

- Q: What machine does the packing carton machine have?

- Packaging equipment including: automatic strapping machine, automatic sealing machine, winding (wrapping) machine, sealing and cutting / shrink machine, vacuum packing machine, automatic strapping machine band and hand tools. Transport equipment mainly include: conveyor belt, roller conveyor, conveyor chain plate, plug-in production line, chain conveyor, conveyor belt etc..

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- There are PLC control ah, if it is fully automatic, then ask the quality of sealing ah, it is best to let manufacturers give you a live demonstration, the soft power depends on the size of the factory, ah, after-sales service ah!

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- Because the packaging machinery is divided into many types, so many species also have different models, basically need to use packaging products requires packaging machinery, if not to fine some, it is necessary to sort of packaging machinery, slowly down. Packaging machinery is not required to use a certain scale, packaging machinery as well as automatic, semi-automatic, manual distinction. Most small workshops, or small factories, are semi automated or manual. If some of the larger factories will use automatic, or even a whole production line to complete automated packaging.

- Q: What are the packaging machines that use temperature control watches?

- Such as shrink machine, vertical packaging machine, pillow type packaging machine, continuous sealing machine,

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

Send your message to us

High Quality Carton palletizing machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords