High Quality Sealing machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Sealing machine made in China

Description of High Quality Sealing machine made in China

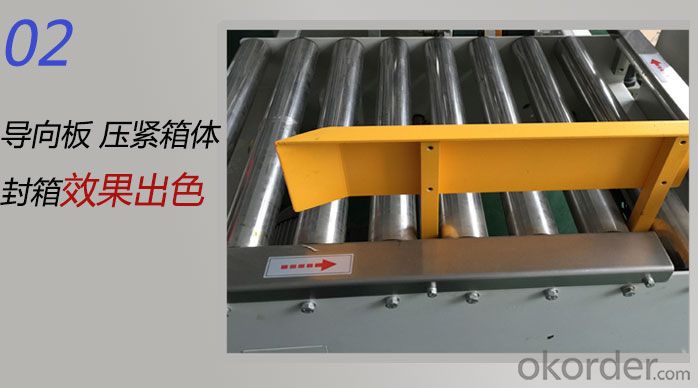

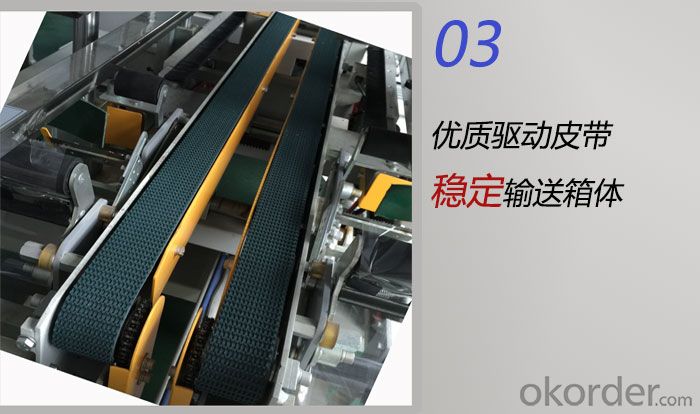

With BOPP adhesive tape as the sealing material, the carton can be sealed up and down at the same time. The motor drive belts on both sides are automatically calibrated and transported. It is fast and stable when sealing. It is suitable for heavy and relatively wide carton. When the auxiliary wheels on both sides assist the machine in sealing, there is no cracking in the middle seam. Table height, carton width height can be adjusted independently, simple and practical. Elegant and generous shape, equipped with blade guards to avoid accidental stab wounds during operation. The parts are stable and durable and have a long service life. The body comes with four high-intensity brake wheels, and the transposition work is very convenient.

Can be wired or stand-alone operation, manually fold the lid, up and down "one" sealed, once completed;

Tape applicator is precise and sturdy, smooth running and long service life;

In addition to the standard specifications, it is also acceptable to widen the machine and increase the height;

Standard machine table height is 600mm;

Using advanced technology to manufacture, use imported brands of electrical controls, gas controls and industry-specific motors;

Main Features of High Quality Sealing machine made in China

1, Good quality imported components:

The carton sealer adopts international advanced technology to manufacture and use imported parts, electrical parts and pneumatic components;

2, Exquisite high-tech international technology:

Has more than 10 years of experience in the development of sealing machines, while introducing and absorbing advanced technologies from Japan, Germany, Italy and other international counterparts in the sealing machine.

3, Unique and beautiful design:

1 The main color of the sealing machine is silver-white, and the machine color suitable for the corresponding production line can also be configured according to the customer's needs;

2 The volume is light, the pulleys are complementary, the displacement is flexible, and it is more convenient to install and debug.

4, Reasonable and powerful function:

1 According to carton specifications, manual adjustment of width and height, convenient and fast;

290° angle machine, cylinder automatic push box;

3 At the same time, the upper and lower corners of the carton are automatically sealed and smoothed, which is fast and smooth;

4 It can be combined with GPA, GPB, GPC models to complete I-shaped sealing.

Specifications of High Quality Sealing machine made in China

| Transfer speed | 0-20m/min |

| Maximum package size | L∞×W500×H500mm |

| Minimum package size | L150×W150×H120mm |

| Power supply | 220/380V 50Hz |

| Consumption function | 240W |

| Apply adhesive tape | W48mm/60mm/75mm (optional) |

| Machine size | L1020×W850×H1350 (without front and rear roller brackets) |

Applications of High Quality Sealing machine made in China

For mineral water, juice, beverage, liquor, beer, infusion bottles and other product development, speciality, stable performance, product packaging, fastening, beautiful.

Images of High Quality Sealing machine made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q: The role of food packaging machinery

- 3) to achieve manual packaging can not achieve the operation, some packaging operations, such as vacuum packaging, inflatable packaging, body packing, isobaric filling, etc., are manual packaging can not be achieved, can only be achieved by mechanical packaging.(4) can reduce labor intensity, improve the working conditions of the labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease. Carton folding machine(5) in favor of labor protection for some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the cost of packing and save the storage and transportation expenses. It can reduce the volume and reduce the packing cost by compressing and packing the loose products, such as cotton, tobacco leaf, silk and hemp. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.(7) ensure product health of certain products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: What are the packing machines?

- Heat shrink packaging machine, mask packaging machine, pillow type packaging machine, food packaging machine, I suggest you can go to see

- Q: Working principle of packing machine

- In the first step, the wrapping paper is pulled down by a bag pulling motor, and then the paper part is supplied with paper according to the signal of the paper feeding sensor, and the wrapping paper is formed through the forming part of the shaper

- Q: What is the name of the paper used in packing machine parts and yellow?

- Also, according to the use of composite PE or textile cloth, in order to improve the physical strength and tightness.Hope to help you.

- Q: What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- English Name: Transparent, film, fold, wrapping, machineClassification: machinery, general machinery and equipment, >>J83 storage equipment, loading and unloading machineryICS classification: packing and conveying of goods, >>55.200 packaging machinery

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Ha ha, as you say, TV factories are closed down, every household has a TV, but every day there will be a lot of people buy tv.

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

High Quality Sealing machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords