High Quality Winding machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Winding machine made in China

Description of High Quality Winding machine made in China

In order to meet the packaging requirements for containerized storage, transportation and mechanized loading and unloading operations, we have designed and manufactured tray-type, dome-type, resistance-pull-type, and pre-pull-type automatic film winding products. This fully automatic winding machine is widely applied to foreign trade exports. , food and beverage, can making, papermaking, dyes, plastic chemicals, glass ceramics, electromechanical castings, and other product assembly costs, increase production efficiency, but also to prevent the damage of the goods in the handling process, and play a role in dust, moisture and cleaning .

Main Features of High Quality Winding machine made in China

★ Suitable for fast transportation or storage;

★ Adaptability, high efficiency and low consumption, reduce labor intensity;

★ It can play a role of dustproof, moisture-proof, and cleaning on the package;

★ Reduce the scratch on the surface of the package, improve the surface quality, and make the package more secure.

1. Automatic feeding, filming, winding, slitting, filming, discharging, storage, etc.

2. Unmanned operation, automatic warning, automatic fault alarm and so on.

3. Easy to operate, durable, robust body design, reasonable and clever combination of mechanical and electrical integration.

Specifications of High Quality Winding machine made in China

| Voltage | 1P、 AC220V/3P 、380V 、50Hz 、2.5KW |

| Pressure | 4~6kg/㎝2 |

| Turntable speed | 0 to 9 laps/minute |

| Turntable diameter | ¢2000mm (common ¢2000, customizable) |

| Roller table height | 450mm (drum type) |

| Roller diameter | 76mm |

| Column height | H2400mm (optional 2000/2700/2900/3000/3100) |

| Packaging material specifications | Width ≤ 500mm Outside diameter ≤ 280mm LLDPE Wrapping Film Stretch film |

| Tray size | Capacity 2000kg; maximum height = column height -400mm |

| Gross weight/net weight | 1400kg (gross weight)/1300kg (net weight) |

| Overall size | L(3000) x W (2000) x H (common 2000mm, customizable) |

Applications of High Quality Winding machine made in China

Applicable to chemical fiber, tobacco, pharmaceuticals, publishing, refrigeration, home appliances, ceramics, beverages, hardware, chemicals, cans and other industries.

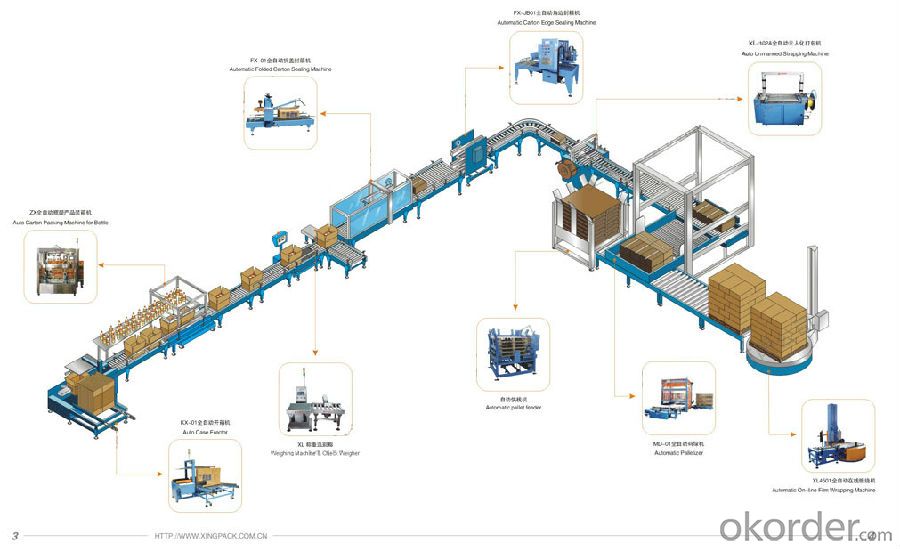

Images of High Quality Winding machine made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q: The role of food packaging machinery

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging. The main functions of packaging machinery are as follows:

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It's a good mechanical design problem! In principle, yes, for example, to achieve the rated torque of the motor. He'll stop by himself! What isn't that great torque? You can zoom in on the load torque

- Q: What machine does the packing carton machine have?

- Do the carton machinery: corrugated production line / single machine, printing machine, polishing machine, laminating machine, mounting machine, die-cutting machine, book paste machine for package machinery: automatic sealing machine, automatic strapping machine

- Q: The role of packaging equipment in packaging equipment

- Some products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.(8) it can promote the development of related industriesPackaging machinery is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, any discipline problems will affect the overall performance of packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.

- Q: What is the name of the paper used in packing machine parts and yellow?

- Also, according to the use of composite PE or textile cloth, in order to improve the physical strength and tightness.Hope to help you.

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine machine standard price of about 38000, excluding tax, tableware packaging machine is designed for tableware (e.g., chopsticks, bowls, dishes and so on) a modern packaging machinery packaging, this machine is mainly composed of conveyor, packaging machine, output machine, shrink machine, composed of four parts.

- Q: What does the mechanical equipment include?

- Rail aligning machine, rail straightening machine, grinding machineSlag shaping machine for track flat car internal combustion engine

- Q: Energy saving reform of packaging machine

- A) the main control circuit is composed of man-machine interface (text display), frequency converter and programmable logic controller (PLC), which constitute the control core;B) the temperature control circuit is composed of an intelligent temperature control meter, a solid state relay and a thermocouple element. The temperature control is accurate, the display is intuitive, and the setting is convenient;C) multi point tracking and detection by photoelectric switches and electromagnetic proximity sensors; 2) fully automatic pillow type working principle:With the improvement of automation, the operation, maintenance and routine maintenance of the packing machine are more convenient and simple, and the professional skill requirements of the operators are reduced. The quality of the product packaging is directly related to the temperature system, the speed accuracy of the main engine and the stability of the tracking system.

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

High Quality Winding machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords