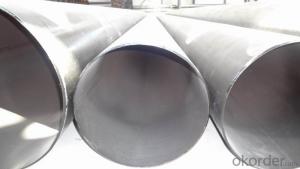

API 5L LSAW STEEL PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LSAW Steel Pipe

1 Size: 219-3200 mm*5-25.4mm

2 Material Q235/Q345/20#/X42-X65/J55 etc

Standard:

EN-10208-1/2, GB9711.1/2 etc.

Steel Grade:

B, X42 up to X70; L245, L290 up to L48

Usage:

Used for Steel Structure

Size:

LSAW from 219.1mm to 3200mm, thickness from 5mm to 25.4mm

Ends: Beveled ends with protector

Surface:

Bare / Varnish coating / FBE, 3PE coating DIN30670 / or by client option

Packing:

Casing, bundled shipping in containers or by break bulk vessel

Process | Longitudinal Submerged- Arc Welded Steel Pipe (DSAW -Double Submerged arc welded) |

Usage | Used for liquid delivery, such as water, gas, and oil; construction and piling |

Standard | API 5L(PSL1,PSL2), ASTM A252,EN10217, EN10219,KS F4602, KS D3583, BS, JIS, IS |

Certificate | ISO 9001:2008, ISO 14001, ISO 18001, API 5L (PSL1, PSL2),EN10217, EN10219 and so on. |

Outside Diameter | 323.9 mm-2134 mm (12"-84") |

Wall Thickness | 6 mm - 80mm |

Length | 6 – 14 m |

Grade | API 5L: GR A, GR B, X42,X46, X56, X60,X65,X70 ASTM A252 GR 1, GR 2, GR 3 EN 10219: S275, S275JR, S355JRH, S355J2H EN 10224, L235,L275,L355 |

Surface | Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Varnish Coating, Bitumen Coating, Black Oil coating as per customer’s requirement |

Test | Chemical Component Analysis, Mechanical Properties (Tensile strength, Yield strength, Elongation), Hydrostatic Test, X-ray Test,Size Inspection. |

Mill Test Certificate | Mill Test Certificate:EN 10204/3.1B |

- Q: What is the difference between carbon steel and stainless steel pipes?

- The main difference between carbon steel and stainless steel pipes lies in their composition and rust resistance properties. Carbon steel pipes are primarily made of iron and carbon, making them less resistant to corrosion and prone to rusting. On the other hand, stainless steel pipes contain chromium, which gives them excellent rust resistance and durability. This makes stainless steel pipes ideal for use in environments where corrosion is a concern, such as in plumbing systems and industrial applications.

- Q: How are steel pipes protected against galvanic corrosion?

- Steel pipes are protected against galvanic corrosion through various methods including the application of protective coatings such as zinc or epoxy, cathodic protection systems, and the use of corrosion inhibitors.

- Q: How do you calculate the flow rate in a steel pipe?

- When calculating the flow rate in a steel pipe, several factors must be taken into consideration. The primary factor to consider is the cross-sectional area of the pipe, which can be determined using the formula A = πr², where A represents the cross-sectional area and r represents the radius of the pipe. Afterwards, it is necessary to ascertain the velocity of the fluid moving through the pipe. This can be accomplished by utilizing the equation v = Q/A, where v denotes the velocity, Q represents the volumetric flow rate, and A represents the cross-sectional area of the pipe. To determine the volumetric flow rate, one can employ the equation Q = AV, where Q represents the volumetric flow rate, A represents the cross-sectional area, and V represents the average velocity of the fluid. Furthermore, it is essential to take into account the properties of the fluid being transported through the pipe. Factors such as density and viscosity can impact the flow rate. In conclusion, the flow rate in a steel pipe can be calculated by determining the cross-sectional area of the pipe, calculating the velocity of the fluid, and considering the properties of the fluid being transported.

- Q: Stainless steel tube, also known as why tube?

- Production methods can be divided into two categories: seamless pipe and welded pipeSeamless steel pipe can be divided into hot-rolled pipe, cold rolled tube, cold drawn tube and extruded tubeWelded pipe is divided into straight welded pipe and spiral welded pipe and so on

- Q: Can steel pipes be used for wastewater treatment systems?

- Yes, steel pipes can be used for wastewater treatment systems. Steel pipes are commonly used in wastewater treatment systems due to their durability, corrosion resistance, and ability to handle high pressure and flow rates. Moreover, steel pipes can be easily welded, making them suitable for various configurations and applications within the wastewater treatment process.

- Q: What is the role of steel pipes in the renewable energy sector?

- Steel pipes play a crucial role in the renewable energy sector by facilitating the transportation and distribution of various energy sources. One significant application of steel pipes is in the construction of pipelines for transporting natural gas, which is increasingly being used as a cleaner alternative to traditional fossil fuels. These pipelines are often made of steel due to its strength, durability, and resistance to corrosion, ensuring the safe and efficient delivery of natural gas to power plants and other energy consumers. Moreover, steel pipes are utilized in the installation of geothermal energy systems. Geothermal energy harnesses the heat from the earth's core to generate electricity or provide heating and cooling. Steel pipes are used to create geothermal wells, allowing for the extraction of hot water or steam from underground reservoirs. These pipes must withstand high temperatures and pressures, making steel an ideal material for this application. Additionally, steel pipes are employed in the construction of hydraulic systems for hydroelectric power plants. These plants rely on the force of flowing water to generate electricity, and steel pipes are used to convey water from the reservoir to the turbines. The durability and reliability of steel ensure the efficient transmission of water, enabling hydroelectric power plants to produce clean and renewable energy. In the renewable energy sector, steel pipes also play a role in the construction of solar power plants. Solar thermal systems use mirrors or lenses to concentrate sunlight and generate heat, which is then transferred to a fluid to produce steam and drive turbines. Steel pipes are essential for circulating and transferring this fluid, ensuring the effective operation of the solar power plant. In summary, steel pipes are indispensable in the renewable energy sector for their strength, durability, and resistance to corrosion. They enable the transportation of natural gas, the extraction of geothermal energy, the transmission of water in hydroelectric power plants, and the circulation of fluids in solar power plants. By facilitating the efficient distribution of various energy sources, steel pipes significantly contribute to the growth and sustainability of the renewable energy sector.

- Q: Can steel pipes be used for underground steam pipelines?

- Yes, steel pipes can be used for underground steam pipelines. Steel pipes are known for their durability and high temperature resistance, making them suitable for transporting steam underground.

- Q: How are steel pipes used in the construction of oil refineries?

- Steel pipes are extensively used in the construction of oil refineries as they are strong, durable, and resistant to corrosion. These pipes are used for various purposes such as transporting crude oil, refined products, and various chemicals within the refinery. They are also utilized in the construction of the refinery's infrastructure, including the fabrication of storage tanks, process equipment, and piping systems that connect different units and sections of the facility. Overall, steel pipes play a crucial role in maintaining the integrity and efficiency of oil refineries.

- Q: Seamless steel pipe 8162 and 8163 what is the difference?

- GB 8162 is the structure of the tube, there is no need for flaw detection, the use of mechanical processing, stents;

- Q: How do you calculate the pipe friction loss coefficient for steel pipes?

- The pipe friction loss coefficient for steel pipes can be calculated using the Darcy-Weisbach equation, which takes into account the pipe diameter, length, roughness, and fluid velocity. The coefficient can be determined by dividing the friction factor (obtained from Moody's chart or using empirical equations) by the Reynolds number (calculated using the fluid properties and pipe dimensions).

Send your message to us

API 5L LSAW STEEL PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords