High Quality Aluminum Coil Material for Refrigerator Condenser Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

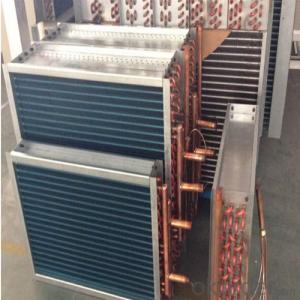

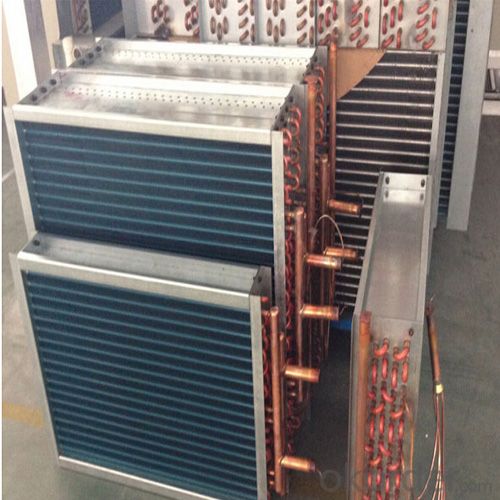

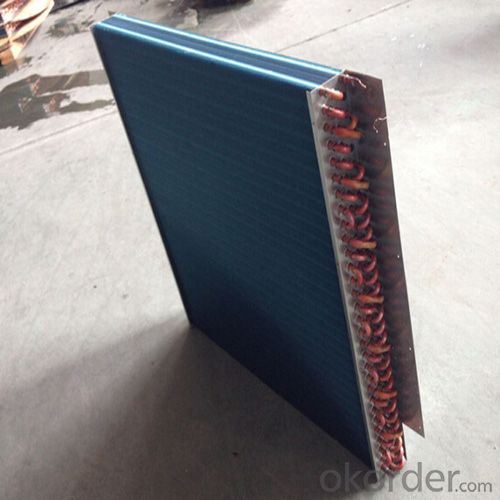

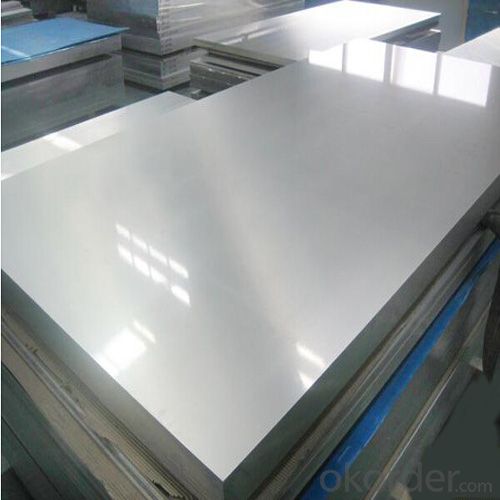

1.Structure of Aluminum Refrigerator Condenser Sheets Description:

Aluminum Refrigerator Condenser Sheets Can be used in a variety of heat exchange constructions where the basic function is to efficiently transfer heat. Also this fin foil can be used for evaporator and condenser in most residential, automotive, and commercial air conditioning units. In addition, this foils are used in humidifiers, dehumidifiers, baseboard space heaters of various types, and other equipment.

2.Main Features of Aluminum Refrigerator Condenser Sheets:

Alloy: 8011, 1100, 1200, 1030B, 3102, 3003

Temper: O, H22, H24, H26

Thickness: 0.08-0.3mm

Core ID: 76mm, 150mm, 200mm, 300mm, etc.

Width: Variety

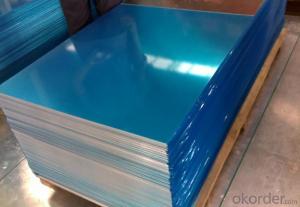

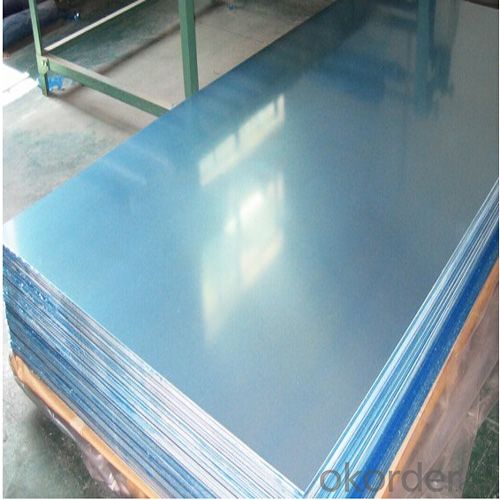

3. Aluminum Refrigerator Condenser Sheets Images:

4. Aluminum Refrigerator Condenser Sheets Specification:

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

1060 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.6 | ||

1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.5 | ||

1100 | 0.95 | 0.05-0.2 | 0.05 | 0.1 | 99.0 | |||||

1200 | 1.0 | 0.05 | 0.05 | 0.1 | 0.05 | 99.0 | ||||

3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | 0.1 | remainder | ||||

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum coils be used for sound insulation purposes?

- Yes, aluminum coils can be used for sound insulation purposes. Aluminum has excellent sound-dampening properties due to its density and ability to absorb and attenuate sound waves. Aluminum coils can be used in various applications such as in HVAC systems, automotive industry, and construction to reduce noise transmission. The coils can be installed in walls, ceilings, or ductwork to create a barrier that blocks or absorbs sound vibrations, thus improving sound insulation and reducing noise levels. Additionally, aluminum coils are lightweight, durable, and resistant to corrosion, making them a reliable choice for sound insulation solutions.

- Q: What are the transportation and storage requirements for aluminum coils?

- There are several factors that determine the transportation and storage requirements for aluminum coils. Firstly, it is crucial to handle the coils with caution during transportation in order to avoid any harm. Secure packaging is necessary to prevent potential scratches, dents, or deformation. Additionally, safeguarding the coils from moisture is essential as exposure to water or high levels of humidity can result in corrosion. During transportation, it is advisable to employ appropriate vehicles or containers that can sufficiently support the weight and dimensions of the aluminum coils. The coils should be firmly secured to prevent any movement or shifting that may cause damage. Regarding storage, it is of utmost importance to store aluminum coils in an area that is clean, dry, and well-ventilated. Ideally, the storage facility should maintain a stable temperature and humidity level to prevent any negative effects on the coils. If the coils are stored outside, they should be adequately covered and protected from direct sunlight, rain, and other weather conditions. Furthermore, it is crucial to store aluminum coils away from any substances or chemicals that may cause damage. They should be stored in a manner that prevents contact with other materials, as physical contact can lead to scratching or other types of damage. In summary, the transportation and storage requirements for aluminum coils involve careful handling, protection from moisture and corrosive materials, proper packaging and securing during transportation, and storage in a clean and suitable environment. By adhering to these guidelines, the integrity of the aluminum coils can be preserved, ensuring their quality and usability.

- Q: Can aluminum coils be used for aerospace applications?

- Yes, aluminum coils can be used for aerospace applications. Aluminum is widely used in the aerospace industry due to its lightweight, high strength-to-weight ratio, corrosion resistance, and excellent conductivity. Aluminum coils are commonly used in various aircraft components such as structural frames, fuselage panels, and wing structures.

- Q: What is the tensile strength of aluminum coils?

- The tensile strength of aluminum coils can vary depending on the specific grade and manufacturing process, but it typically ranges from 25,000 to 45,000 pounds per square inch (psi).

- Q: Can aluminum coils be painted or coated after installation?

- Yes, aluminum coils can be painted or coated after installation.

- Q: Are aluminum coils resistant to corrosion?

- Yes, aluminum coils are highly resistant to corrosion due to the natural oxide layer that forms on their surface, protecting them from environmental factors.

- Q: This question asks about the maintenance difficulty of aluminum coils.

- <p>Aluminum coils are relatively easy to maintain. They are resistant to corrosion and do not require frequent cleaning or special treatments. Regular inspection for any physical damage or signs of wear is sufficient. However, it's important to keep them dry and clean to prevent any potential issues. For specific applications, such as in HVAC systems, regular cleaning may be necessary to ensure optimal performance. Overall, maintenance is minimal compared to other materials.</p>

- Q: I have a electrical project to do, and could save about $300.00 by using aluminum wire since I can get it free, but I have never used aluminum before, and am not sure if it is a good way to go.

- I would not recommend it. Aluminum wire expands and contracts a great deal causing the connections to become loose, or break. That is what I was taught.

- Q: Can aluminum coils be used in the production of aluminum composite panels?

- Yes, aluminum coils can be used in the production of aluminum composite panels. Aluminum coils are often used as the base material for manufacturing aluminum composite panels (ACP). ACPs are made by bonding a thin aluminum coil to a thermoplastic core using a bonding adhesive. The aluminum coil provides strength and stability to the panel while the thermoplastic core offers insulation and rigidity. The use of aluminum coils allows for flexibility in design and customization of the panels. Additionally, aluminum coils are durable, lightweight, and resistant to corrosion, making them an ideal choice for ACP production.

- Q: What is the flexural strength of aluminum coils?

- The flexural strength of aluminum coils varies depending on the specific grade and thickness of the aluminum used. Generally, aluminum coils have good flexural strength due to the inherent properties of aluminum, which is known for its high strength-to-weight ratio.

Send your message to us

High Quality Aluminum Coil Material for Refrigerator Condenser Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords