High Purity Whiteness Aluminium Powder Al2O3 for Refractory Raw Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Pure Whiteness Aluminium Powder Al2o3

It is a kind of aluminate cement wrought material based upon calcium aluminate, it is called Aluminate cement when it has been finegrinded to hydraulicity cementing material, its code is CA. When the cement has a grinded Al2O3 content of above 68%, it can be added with appropriate amount of α-Al2O3 powder as requirement.

Application:

1. aluminium oxide for aluminium smelting, glass, ceramic industry etc.

2. aluminium oxide for refractory, coating, abrasive applications.

3. aluminium oxide for electric basal plate, desiccating agent, chemical and pharmacy industry, etc.

aluminum oxide property:

It has higher hardness and slight lower toughness comparing with brown fused alumina. It is also characterized by its high purity, ability of self-sharpening, better cutting, less heat emit, higher efficiency, acid and alkali resistance, good thermal stability. As the abrasive materials, it is suitable for grinding high-speed, high carbon steel, as loose grains, it widely used for bonded and coated abrasives , polishing, precision casting and so on .

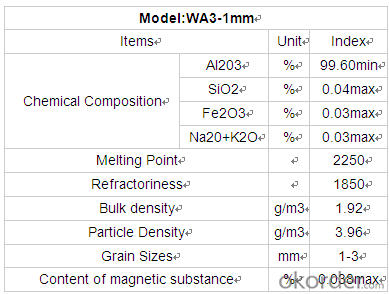

white fused alumina grits&powder chemical composition

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q: What does fire-resistant insulation coating have?

- Refractory thermal insulation material mainly refers to the inorganic thermal insulation material and composite thermal insulation material. According to the shape, it can be divided into: Finishing of fibrous shape, mineral?cotton, rock wool, glass wool, aluminum?silicate?wool, ceramic fiber, etc. Diatomaceous earth of microporous pile, calcium silicate, expanded perlite,expanded vermiculite,aerated concrete, etc. Foam glass of bubble shape, volcanic ash glass, foamed clay, foamed?concrete, gelatine powder polyphenyl granule heat insulating slurry of pasty form, etc. Their common feature is fire-retardant and firproof. It can be used in buildings with high requirements of fire?rating. Calcium silicate, aluminum silicate and asbestos can also be used for piping insulation of heat transport with high temperature.

- Q: who knows the fire resistant levels of fireproofing glass?

- According to the fire resistance levels, it can be divided into three categories: Class A: a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. Including composite flameproof?glass and perfusion type fireproofing glass . This kind of glass has the properiyies of transmittance, fireproofing ( smoke insulation, fireproofing, and keeping out thermal radiation), sound insulation, shock resistance, and it's suitable for steel and wooden fire door of building decoration, windows, varnishing, partition walldaylighting?roof,ceiling?screen,perspective floor and other construction components demading for transparency and fireproofing. Class B: Marine fireproofing glass, including porthole fireproofing glass and rectangular window fireproofing glass, surface glass pane is tempered safety glass, the inner surface glass pane material can be arbitrary selection. Class C: it's a kind of monolithic fireproofing glass that only satisfies the requirements of refractory integrity. This kind of glass has characteristics of transmittance, fireproofing, smoke insulation and high strength,etc. It's suitable for fireproofing glass partition wall, fire Windows, outside curtain wall and other places without insulation requirements.

- Q: How can refractory materials be divided?

- There are many criteria for the classification of refractories.Just referring to a book about refractory.

- Q: What problems should be paid attention to while using refractory materials under a controlled atmosphere?

- Pay attention to the performance of the materials, and the use of non oxide materials!

- Q: What brands are the best in the A-level refractory materials?

- These brands are good.

- Q: Is fireclay corrosive?

- No. All of the refractory materials have stable chemical properties and their usability can be guaranteed under high temperatures.

- Q: What defect does fused cast refractories have ?

- The impact on the quality of glass is mainly the defects that eroded down refractory materials mixed in the glass, thus being prodeced of grass products. Defects are mainly foreign body defects such as sand, knot and wave reinforcement.

- Q: What is the interior fireproof thermal insulation material?

- The methods of thermal insulation wall have three kinds of materials. First: gypsum board or cement board are stuck outside the polyphenyl board; second: lightweight brick build; third: infill polyphenyl board, lightweight brick is built outside. The first two has almost the same price. The latter is slightly expensive. 60 yuan / square meter is not very expensive!

- Q: Why should graphitic refractory materials be used now that graphite can burn?

- C is inactive in nature. Carbon will not burn unless the temperature is about 2000℃, so it can't be lit generally. Coal can be lit because it contains other combustible substance which ignite carbon indirectly. While graphite, carbon black, is more pure and dense than coal., so it is hard to oxidize.Their molecular structures are also different, just like diamond is harder than graphite.

- Q: What are the additives and recipes of refractory?

- SM water reducing agent

Send your message to us

High Purity Whiteness Aluminium Powder Al2O3 for Refractory Raw Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords