High Output CMAX Series PB&YPS-FP Sheet,Plates,Foam Coil Material Crusher extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1.can solve the problem of width of sheet,platesand foam coil materical.

2.this serice add a set of haul-off device,two sets of press roller,air press controller.

3.the line speed can reach 30m/min

4.capacity is higher

5.main axis is processed with high quality steel after verifying the balance.

6.the rotor adopts 'V''type cutting technology

7.the CMAX-FP adopts box water cooling system,which avoid sticking the blade because of the heating of materical.

8.we can provide material collection device and powder separation system according to customer's requirements

Specifications

Certification: CE SGS,ISO9001,UL,TUV

1.High capacity

2.Good quality and reasonable price

Our Services

1) Presale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Mediumsales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export

3) Aftersales service: We sent engineer to the scene to guide installation, debugging and training operators.

4) we provide engineers available to service machinery overseas

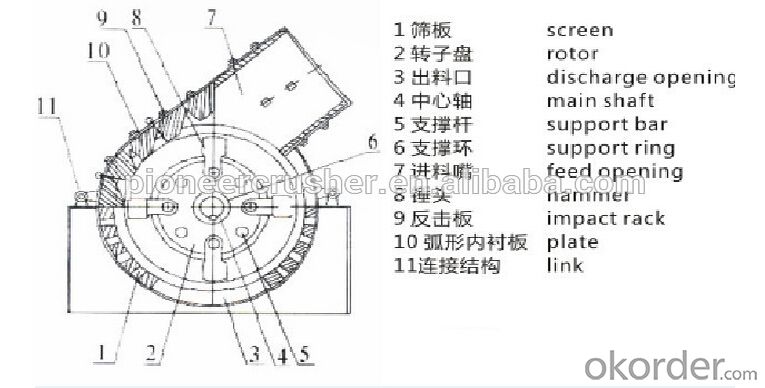

product show

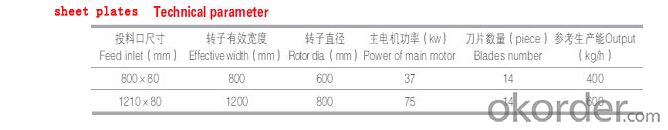

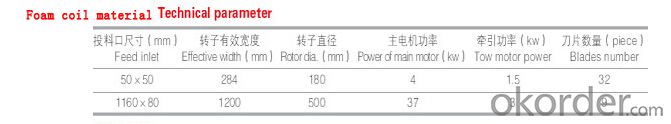

technical data

sheet plates technical

foam coil materical

FAQ:

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: What type of crusher is good for heavy crusher?

- The machine can replace the traditional jaw crusher and counterattack crusher two stage crushing, the user can save a lot of investment in equipment, and can produce grain shape excellent products.

- Q: What is the noise produced by a plastic crusher?

- Crusher, the machine adopts imported high-quality tool steel, special tool is particularly durable, the tool installation design can be adjusted and adjusted, with more blunt after more grinding, repeated use many times, long service life. Use ball bearings, center fixed, running balance, no vibration

- Q: How do you make plastics into particles?

- The plastic products are broken into small pieces in a plastic crusher,

- Q: Plastic crusher does not eat what is the reason?

- You have to tell people what you're crushing, for example

- Q: How should the plastic crusher blade be ground?

- First sharpen the edge of the blunt knife, then fine grinding, sharpening the sharp edge

- Q: PVC what's the best blade for plastic crushers?

- 65Mn the most common, cheap, very sharp, the drawback is not wear-resistant. Grinds the blade original, feels that gives the minute Oh!

- Q: Packing belt above hasp can't get rid of buy a crusher can I directly broken is broken belt

- In the recycling process of waste plastics, waste a lot of it contains a lot of iron

- Q: PVC how much is a plastic crusher?

- About fifteen thousand, I do this, welcome to ask or see my space

- Q: What are plastic particles? What's the use?

- Hardened than polyethylene. Mainly used for pots, barrels, furniture, thin film, woven bag, packing belt, bottle?, bumper. PE recycled plastics: Polyethylene (PE) - no coloring milky white translucent, waxy; touch smooth feeling, soft and tough, slightly can pull long. Low density polyethylene is relatively soft, good transparency, high density polyethylene hard. Mainly used for plastic film, bag, water pipe, oil PS is a polystyrene plastic, easy coloring, good transparency, and more for the production of shades, toothbrush handles, toys, electrical parts and components. It is resistant to acid corrosion, but soluble in chloroform, two chlorine ethylene, bananas, water and other organic solvents. PVC is a PVC, bright color, corrosion resistant and durable. Due to an increase in the manufacturing process of plasticizer, anti aging agent and other toxic and auxiliary materials, so its products Foods and drugs are not stored. ABS is made from acrylonitrile and butadiene

- Q: What's the price of used plastic crushers?

- Like the crusher is basically a price, a point of goods, basically the price will not be very low.

Send your message to us

High Output CMAX Series PB&YPS-FP Sheet,Plates,Foam Coil Material Crusher extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches