CMAX Series Strong Crusher For Small Size Pipe/Sheet Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1.can solve the problem of width of sheet,platesand foam coil materical.

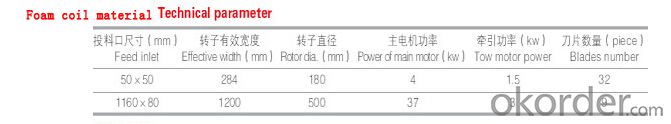

2.this serice add a set of haul-off device,two sets of press roller,air press controller.

3.the line speed can reach 30m/min

4.capacity is higher

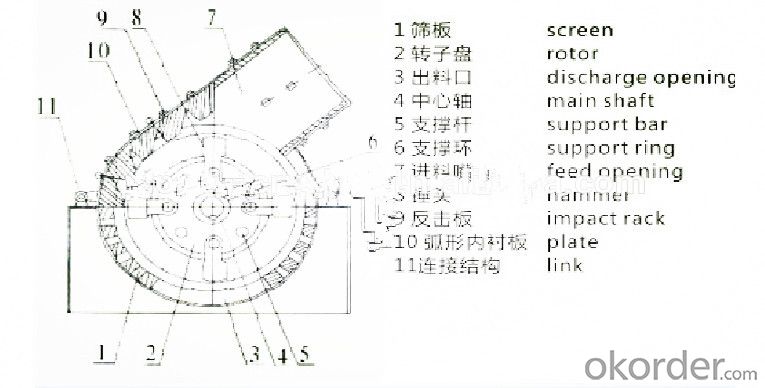

5.main axis is processed with high quality steel after verifying the balance.

6.the rotor adopts 'V''type cutting technology

7.the CMAX-FP adopts box water cooling system,which avoid sticking the blade because of the heating of materical.

8.we can provide material collection device and powder separation system according to customer's requirements

Specifications

Certification: CE SGS,ISO9001,UL,TUV

1.High capacity

2.Good quality and reasonable price

Our Services

1) Presale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Mediumsales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export

3) Aftersales service: We sent engineer to the scene to guide installation, debugging and training operators.

4) we provide engineers available to service machinery overseas

product show

technical data

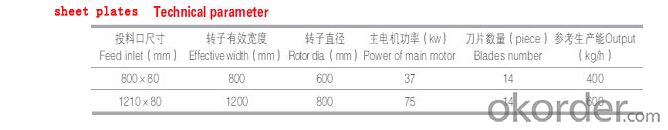

sheet plates technical

foam coil materical

FAQ:

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: Plastic grinding machine mainly grinding PVC grinding material thickness of about 20 silk finger cover size, which kind of pulverizer is suitable for this purpose?

- Overview of plastic grinding machine compared with the same type of milling machine, under the same power output is greatly improved (increased by 20%-50%), saving about energy consumption of the dust collector is added to effectively reduce dust pollution, the discharging of the main fan reduces the labor intensity of workers and open the door cover of the host can be replaced, which is convenient for maintenance and the tool windand watercooling system reduce the working temperature inside the machine body, the grinded material uneasy degeneration

- Q: How to dust the plastic crushing material?

- The dust removal system always operates in the most energy-efficient condition. The system comes with explosion-proof and explosive discharge devices, so that the use of more secure. The structure of this system is modular composite structure, each component has been strictly chemical derusting, degreasing, phosphating, paint, paint, aesthetic texture, corrosion resistance. Basic parameters: handling air flow: 2500m3/h--100000m3/h. running resistance: lower than 1000pa. emission index: lower than 80ml/m3., core components imported, 3 years free maintenance

- Q: How to calculate the crushing capacity of a coal crusher?What's the formula?

- Crusher because of improper use often leads to the phenomenon of death, so in the crusher, crushing the material, must pay attention the degree of uniformity of the material, there is the hardness of the material properly, if good, can be coupled with a process.

- Q: How do you melt plastics?I would like to waste plastic (such as: pots, shells), melting and forming, as a useful equipment shell (such as: sound shell). But plastic is non crystal, how to melt like a crystal, please advise!

- The same kind of waste plastics can be broken and cleaned by plastic crusher, and then heated, melted and extruded by plastic extruder

- Q: What kind of heating machine is better for the recycled plastics factory? How long does the crusher sink need to be cleaned?

- Of course, the crusher is the longer the better, if conditional, get two sinks, the effect is better

- Q: Plastic crusher does not eat what is the reason?

- You have to tell people what you're crushing, for example

- Q: What's the difference between a domestic crusher and another crusher?

- (2) the characteristics of the tire type mobile crushing station:The tire type mobile crushing station is a new product which is convenient for building waste to be broken down in accordance with the domestic market. The combination of flexible, adaptable: all kinds of crusher station with a variety of configurations, the user can according to their needs choice configuration, according to the requirements of the crushing process composed of different "first crushed sieve", but also the composition of the first screen after the broken process, crushing and screening can also be used alone. The crushing station can be divided into two sections of crushing and screening system according to actual demands, which can be combined into three sections of coarse, medium and fine crushing and screening system.

- Q: Why plastic crushers are closely related to environmental protection?

- Because there is a good plastic crusher, which means that the plastics recycling industry market will be better development

- Q: I want to make a plastic lid ~ ~ big barrel gasoline barrel diameter of about 58cm ~ ~ want to own processing to use what machine? How much, approximately? Where can I sell it?Every year I have about 200 thousand orders of more than cover any kind of high efficiency ~ ~ automation machine?? Can the 2~10 million machine be satisfied? And is the maintenance cost of the machine expensive?

- Machine maintenance costs include hydraulic oil costs, electrical components costs, 2~5 yuan per year. The above estimate, the detailed estimate should be based on the advanced level of equipment and manufacturers, and I hope you can carefully select the products suitable for your products.

- Q: Hello everyone! I am engaged in waste plastics crushing a small factory repelleting, I have a crusher is crushing all kinds of waste plastic bottles, plastic blocks and pipes, with cleaning one broken, can put the screen into big hole, and then smash PP and PE agricultural waste sacks film can be used? You have experienced elder brother to help, thank you little brother

- Plastic properties are not the same, separate cutting, pipes need relatively strong crusher, such as broken PET, because of heat will crystallize, in the process of cutting through the tear will inevitably lead to molecular damage, there is need to consult

Send your message to us

CMAX Series Strong Crusher For Small Size Pipe/Sheet Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords