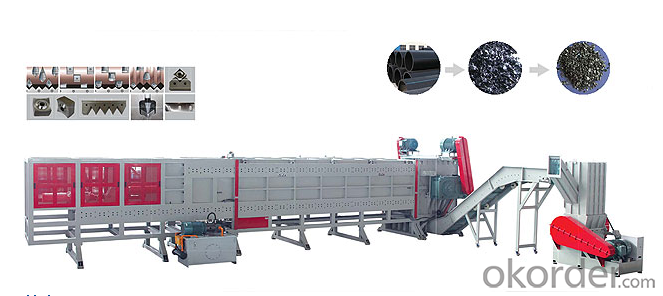

CMAX Plastic Pipe Shredder Unit For PE/PP/PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard wooden case as usual |

| Delivery Detail: | Within 15 days after receipt of the deposit |

plastic pipe recycled bottle shredder unit

XIECHENG 30HP/22KW Crusher for Plastic Industry

1. Suitable for recycle of plastic casing, thin tube plastics, injection and mould sector, bottle plastics and shell plastics;

2. cmax series are easy to operate and simple to replace cutters. Spacious flat blade is suitable to granulate bulky and thin plastics, increases efficiency; installed with electrical safety devices; double wall hopper with sound-proof material. Motor is equipped with overload protector, and power protection devices. Safety and environmental protection, low electricity consumption and durable. Stainless steel hopper for all models is available.

plastic pipe crusher,large diameter plastic pipe crusher,plastic pipe crusher shredder machine

product show

Technical parameter:

Model | Feed dia.(MM) | Rotor blade swing diameter(MM) | rotor speed | Drive power | Max shredable pipe | Mechanical pusher power | OUTPUT(KG/H) |

CMAX-630 | 750*790 | 848 | 39 | 2*30 | 630 | 11 | 800-1000 |

CMAX-800 | 950*950 | 1028 | 33 | 2*37 | 800 | 11 | 1000-1200 |

CMAX-1000 | 1140*1160 | 1258 | 27 | 2*45 | 1000 | 15 | 1200-1500 |

CMAX-1200 | 1340*1360 | 1478 | 23 | 2*55 | 1200 | 15 | 1500-2000 |

- Q: How to operate a plastic crusher correctly?

- Ji made machinery for you to answer your questions.I wish you a happy life!!

- Q: Working video of aluminium crusher

- The aluminum is not high enough, the crusher needs to consider separating from other metal, no video can't be delivered here. It needs the equipment to call me!

- Q: How do you melt plastics?I would like to waste plastic (such as: pots, shells), melting and forming, as a useful equipment shell (such as: sound shell). But plastic is non crystal, how to melt like a crystal, please advise!

- The same kind of waste plastics can be broken and cleaned by plastic crusher, and then heated, melted and extruded by plastic extruder

- Q: What kind of heating machine is better for the recycled plastics factory? How long does the crusher sink need to be cleaned?

- Your shaft is broken. Is it too deep at the bottom of the bar to eat too much? The exhaust is empty and the material is normal

- Q: Plastic crusher does not eat what is the reason?

- You have to tell people what you're crushing, for example

- Q: Why plastic crushers are closely related to environmental protection?

- Plastic recycling has developed, and that has important implications for environmental protection

- Q: PVC how much is a plastic crusher?

- About fifteen thousand, I do this, welcome to ask or see my space

- Q: How do plastic particles agglomerate?

- First of all, to determine if due to softening, resulting in plastic particle agglomeration, moreover, is only after aging together.

- Q: Which industries will buy crushers?

- Gravel factory, sand making factory. Will buy a crusher. I suggest that we buy a crusher and buy Xin Yun heavy industries. Quality assurance is king..

- Q: In hard rock foundation construction, can not be carried out burst, crusher does not move. Is there any good way?

- Cutting machine cutting width; or hammer drilling; then using hydrochloric acid into the reaction -- so, there will be a lot of smoke; such a circle, forming a hole diameter of 1 meters. Then it can be built with static blasting.

Send your message to us

CMAX Plastic Pipe Shredder Unit For PE/PP/PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords