Silica Brick for Stoves - Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Silicon Carbide Fines Silica Refractory Brick

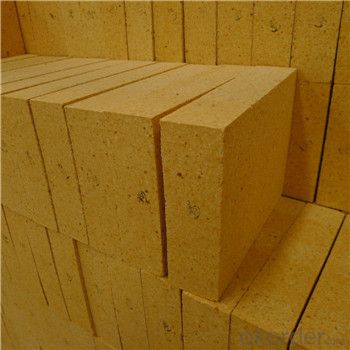

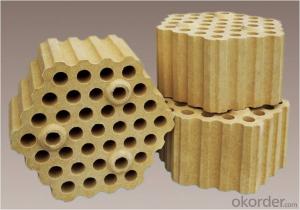

CMAX Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening,mixing, pressing, drying and sintering. zircon brick is characterized by good thermal stability and resistance to corrosion and erosion of glass liquid. They are used for high temperature equipment in the glass furnace, molten steel ladle and continual casting water month.

Silica bricks for hot stoves feature sharp dimension,low expansion,little residual quartz, low true density.low creep rate,good thermal shock resistance upon 600°C and high refractoriness under load, It mainly used at high temperature area include arch and upside of hot stove and upside of checker.What’s more, we are main supplier of Morgan .

Product Applications:

Silica Brick are ideal for use in the below applications

Furnaces of metallurgy industry, heat treatment furnace

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace

Standard sizing: 230 x 114 x 65 mm others up to the clientKiln car building

For ladle

Product Advantages:

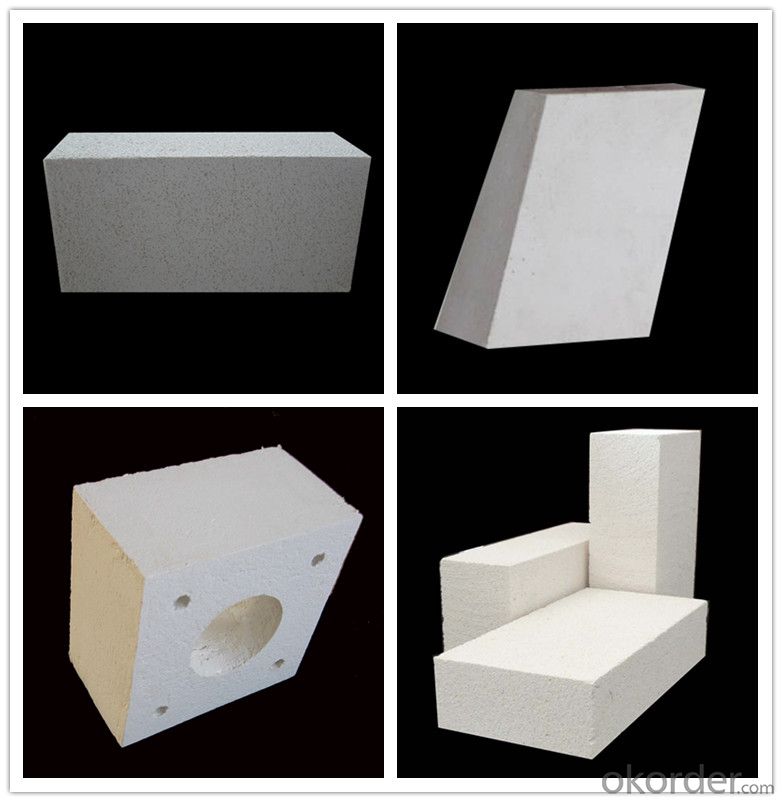

With dense and smooth appearance, uniform corner and edge, pure color and luster and accurate size.

Silicon oxide is above 95%.

Good acid erosion resistance.

High softening point with temperature.

No shrink in burn repeatedly.

Temperature of refractoriness under load is above 1650º C

Stable Capability, High Quality, Excellent Service, Competitive price is the most important advantage of our products.

Main Product Features:

Low bulk density, low thermal conductivity, good thermal insulation performance.

Refractory category allow direct contact of fire, suitable ofr various atmosphere

Good integrity with furnace lining, long service life, easy operation, could be shaped freely

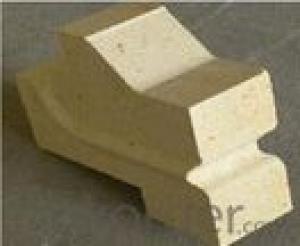

Product specification: standard form, normal standard, shaped and special shaped bricks.

Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the most widely used.

Product Specifications:

ITEM | For Hot-Blast Stoves | For Glass Furnace | ||||||

S-94 | S-95A | S-95B | G-94 | G-95A | G95-B | G-96A | G-96B | |

SiO2, % | ≥94 | ≥95 | ≥95 | ≥94 | ≥95 | ≥95 | ≥96 | ≥96 |

Fe2O3, % | ≤1.5 | ≤0.5 | ≤1 | ≤1.5 | ≤1.2 | ≤1.2 | ≤0.8 | ≤1 |

Residual Quartz, % | ≤1 | ≤1 | ≤1 | ≤1 | ||||

Apparent Porosity | ≤23 | ≤23(24) | ≤21(23) | ≤24 | ≤22(24) | ≤22(24) | ≤22(24) | ≤22(24) |

True Density, g/cm3 | ≤2.35 | ≤2.34 | ≤2.33 | ≤2.35 | ≤2.35 | ≤2.34 | ≤2.34 | |

Cold Crushing Strength, Mpa | ≥29.4 | ≥30(27) | ≥30(20) | ≥30 | ≥30(35) | ≥30(35) | ≥30(35) | ≥30(35) |

Refractoriness Under Load, ℃ | ≥1650 | ≥1600 | ≥1630 | ≥1660 | ≥1650 | ≥1680 | ≥1670 | |

Permanent Linear Change, % | 1500℃X4h, ±0.2 | 1450℃X2h, ±0.5 | ||||||

FAQ:

Q1: Are you a manufacture or trader?

A: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A: We have our own factories and excellent technical team, and we accept OEM service.

Q5: What certificates do you have?

A: ISO9001 and Test Report, also we can do other necessary certification according to your requirements.

Q6: Can you offer samples?

A: Of course,samples are total free! Freight should be paid by buyers.

Product Picture

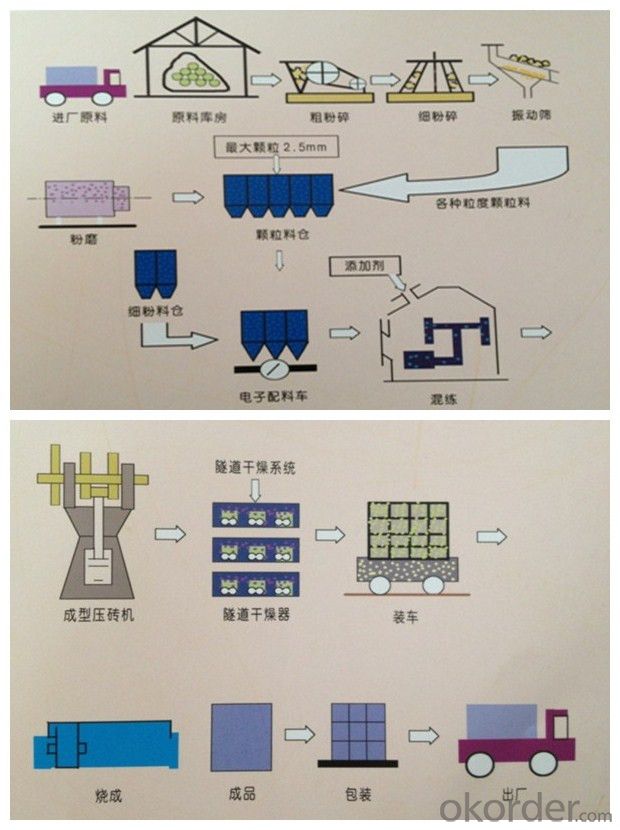

Produce Processing

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- Small fluctuations in the chemical composition do not have a significant effect on use. The key is the operation of the electrolyzer in production to determine whether the side wall will be damaged.

- Q: The introduction of silica brick

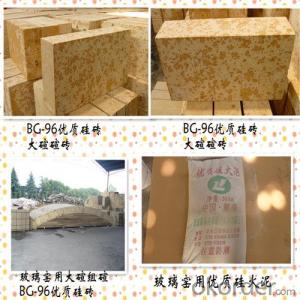

- Brick refers to the content of more than 93% products SiO2. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system. The higher the content of SiO2 in silica raw material, the higher the refractoriness of the product. According to the use of brick varieties, divided into: coke oven silica brick, brick for hot blast stove, electric stove with brick, brick for glass furnaces. According to the transformation is divided into: standard bricks, tiles, bricks and general special brick etc..

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use,

- Q: What is acid refractory?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: What role does silica play in refractories?

- The natural mineral of silica is called quartz. In refractories, silica and siliceous refractory materials contain more silica. Silica is acidic at high temperature, and siliceous refractory can resist acid slag corrosion

- Q: Brick

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Add 1.8-2.2% of the total weight of the main raw material, and then add lime milk, rolling for 10-15 minutes, and finally add pulp, rolling for 10-15 minutes, out of the mill, forming billet.

Send your message to us

Silica Brick for Stoves - Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords