All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Are refractory bricks resistant to chemical attack?

Yes, refractory bricks are highly resistant to chemical attack. They are specifically designed to withstand the corrosive effects of various chemicals, making them a reliable choice for applications where chemical resistance is required.

What are the advantages of using refractory bricks?

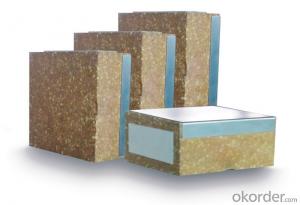

The advantages of using refractory bricks include high heat resistance, excellent durability, low thermal conductivity, and resistance to chemical corrosion, making them ideal for applications in furnaces, kilns, and other high-temperature environments. Additionally, refractory bricks offer dimensional stability, easy installation, and can be recycled, providing cost-effectiveness and environmental benefits.

Can refractory bricks be used for carbon black furnaces?

Yes, refractory bricks can be used for carbon black furnaces. Refractory bricks are known for their high temperature resistance and durability, making them suitable for withstanding the extreme heat and harsh conditions inside carbon black furnaces. Additionally, these bricks offer good insulation properties, ensuring efficient heat transfer and containment within the furnace.

Can refractory bricks be used in aluminum smelting?

Yes, refractory bricks can be used in aluminum smelting. These bricks are specifically designed to withstand high temperatures and chemical reactions, making them suitable for lining furnaces and other equipment used in the aluminum smelting process.

How do refractory bricks contribute to reducing air pollution in industrial processes?

Refractory bricks contribute to reducing air pollution in industrial processes by providing a high temperature-resistant lining in furnaces, kilns, and other high-temperature equipment. This lining prevents the escape of harmful gases, particulate matter, and pollutants into the atmosphere. By containing and insulating the heat within the equipment, refractory bricks minimize the need for excessive fuel consumption, thus reducing emissions of greenhouse gases and air pollutants. Additionally, the durability and longevity of refractory bricks minimize the need for frequent replacements, reducing waste generation and further environmental impact.

Wholesale Refractory Bricks from supplier in Madagascar

Our team of experts will guide you through the entire procurement process, from selecting the right type of refractory bricks for your specific needs to providing competitive pricing and timely delivery. We understand the unique challenges and requirements of the Madagascar market and can offer customized solutions to meet your project's demands.

Whether you need refractory bricks for high-temperature applications, insulation purposes, or any other specific requirements, we have a wide range of products to choose from. Our partnerships with leading manufacturers ensure that you receive high-quality products that meet international standards.

Furthermore, our technical support team is available to assist you with any queries or concerns you may have. We can provide guidance on installation, maintenance, and troubleshooting to ensure optimal performance and durability of the refractory bricks.

At CNBM, we pride ourselves on our commitment to customer satisfaction. We strive to build long-term relationships with our clients by providing reliable and efficient services. With our expertise and experience in the Madagascar market, we are confident in our ability to meet your refractory brick needs.

Contact us today to discuss your requirements and let us assist you in procuring the best refractory bricks for your projects in Madagascar.

Whether you need refractory bricks for high-temperature applications, insulation purposes, or any other specific requirements, we have a wide range of products to choose from. Our partnerships with leading manufacturers ensure that you receive high-quality products that meet international standards.

Furthermore, our technical support team is available to assist you with any queries or concerns you may have. We can provide guidance on installation, maintenance, and troubleshooting to ensure optimal performance and durability of the refractory bricks.

At CNBM, we pride ourselves on our commitment to customer satisfaction. We strive to build long-term relationships with our clients by providing reliable and efficient services. With our expertise and experience in the Madagascar market, we are confident in our ability to meet your refractory brick needs.

Contact us today to discuss your requirements and let us assist you in procuring the best refractory bricks for your projects in Madagascar.

Hot Search

- Monolithic Refractories in Uruguay

- Ceramic Fiber Products in Singapore

- Refractory Bricks in Botswana

- Raw Materials For Refractory in Iceland

- Ceramic Fiber Products in Sweden

- Refractory Bricks in Gabon

- Monolithic Refractories in Austria

- Monolithic Refractories in Burundi

- Ceramic Fiber Products in Samoa

- Refractory Bricks in South Africa