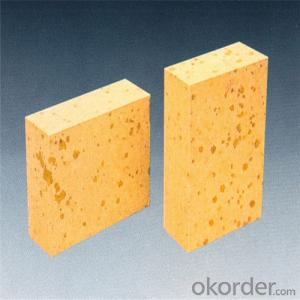

Silica Brick for High Temperature Glass Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features:

1.Good acid and erosion resistance, powerful anti high-temperature strength.

2.Soften melting temperature is 1620~1670 °C.

3.Low thermal shock resistance.

4.Natural silica as raw material, plus regular mineralizer.

5.Ensure good bonding and structural strength of furnace.

6.Good heat resistance and long service life.

Application:

1.Glass melting furnace, ceramic frit kiln, sodium silicate furnace, soaking furnace, ceramic kiln, etc

2.Coke oven's coking chamber, combustion chamber walls, steel open-hearth's regenerator and sediment chamber, etc.

3.Load-bearing parts of high temperature hot air furnace and acid open-hearth furnace roof, etc.

Item | Properties | |||

BG-96A | BG-96B | BG-95A | BG-95B | |

SiO2,% | 96 | 96 | 95 | 95 |

Fe2O3 ,% | 0.8 | 1.0 | 1.2 | 1.2 |

Melt index,% Unit weight<20kg< span=""> Unit weight≥20KG |

0.5 0.6 |

— — |

0.7 0.7 |

— — |

Cold Crushing strength MPa, Unit weight<2kg< span=""> Unit weight≥20KG |

35(30) 30(25) | |||

Softening temperature under load,°C | 1680 | 1670 | 1660 | 1650 |

Apparent porosity % | 22(24) | |||

Bulk density,g/cm3 | 1.85-1.9 | |||

True density,g/cm3 | 2.34 | 2.35 | ||

Application | sodium silicate furnace,ceramic frit furnace ,glass furnace,coking furnace, metallurgical furnace and other furnaces | |||

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: Physical solid waste disposal

- The production of silicon material is added to the cause of waste brick:Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products during firing

- Q: The introduction of silica brick

- Brick refers to the content of more than 93% products SiO2. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system. The higher the content of SiO2 in silica raw material, the higher the refractoriness of the product. According to the use of brick varieties, divided into: coke oven silica brick, brick for hot blast stove, electric stove with brick, brick for glass furnaces. According to the transformation is divided into: standard bricks, tiles, bricks and general special brick etc..

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on. The properties and process of silica crystal with SiO2 transformation is closely related, therefore, the proportion of it is one of the important quality indexes of silica brick. General requirements below 2.38, high quality silica brick should be less than 2.35. The true density is small, reflecting a large number of scale quartz and square quartz in the brick, the residual quartz is small, so the residual line expansion is small, and the strength is decreased in useThe raw materials for the manufacture of silica brick. The higher the SiO2 content of silica raw material, the higher the refractoriness. The most harmful impurities are Al2O3, K2O, Na2O and so on. They seriously reduce the refractoriness of refractory products. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer (e.g. millscale, lime) and binder (such as molasses, sulfite pulp waste liquid), after mixing, molding, drying, sintering and other processes in the system.

- Q: What role does silica play in refractories?

- The natural mineral of silica is called quartz. In refractories, silica and siliceous refractory materials contain more silica. Silica is acidic at high temperature, and siliceous refractory can resist acid slag corrosion

- Q: The brick is mainly used in the place?

- Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Can generate the material needs is the best way to see the impurity problem!! the first consideration is whether can get the material impurities with what method choice after the time! Miscellaneous reactions cannot have new impurity formation! Selected cannot and need material reaction reagent!

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- That is because the brick load softening point the maximum temperature is 1450 degrees.

Send your message to us

Silica Brick for High Temperature Glass Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords