China Graphite Electrode Production - RP HD HP UHP Graphite Electrodes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Graphite Electrodes:

We have full set of production line for graphite electrodes. Our products are characterized by superior compact structure, good electrical and thermal conductivity, high resistance to oxidation and corrosion in high temperature. The regular power graphite electrodes are used in metallurgy industry for refining, such as EAF furnaces of steel plant and other applications. As one of the most professional graphite electrode manufacturers in China, passed ISO9001:2000 certified. We're glad to quote you a most competitive price according to your specification.

2.Main features of Graphite Electrodes:

1).Good electrical conductivity

2).High resistance to thermal shock

3).High mechanical strength

3. Graphite Electrodes Images:

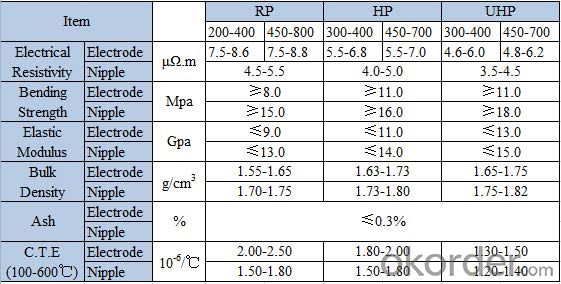

4. Graphite Electrodes Technical Parameters:

Diameter: from 50mm to 600mm (2" to 24")

Grades: including RP, HP, UHP.

Nipples: 3 TPI or 4 TPI.

Application: Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Graphite Electrodes is one of the large scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Classification, uses and manufacturers of graphite electrodes

- The difference between graphite electrodesMainly from the current, density, resistance, bending strength, ash parameters are measured

- Q: What is the difference between pyridine type nitrogen and graphite type nitrogen?

- The fine structure graphite is the raw material used in the production of graphite electrode. The particle size is relatively small, generally below 0.5.

- Q: Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- Can't。 During electrolysis, there is depletion of sulfite ions.

- Q: What is the role of the Pt electrode? What is the difference between the graphite electrode and the graphite electrode?

- Carbon electrodes, however, are less likely to be less controllable because of their microstructure, or have some effect on the electric field, if they are sensitive signals

- Q: MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- Carbon deposition can cause insufficient combustion of gasoline and cause engine chattering.

- Q: How should carbon deposits be treated?

- In this way, can keep the engine seal, to prevent oil because the gap is too large and rampant, buried carbon curse generation "".

- Q: Graphite graphite graphite graphite electrode what is the use?

- Natural graphite electrode is the main raw material with graphite, high purity flake graphite powder or high carbon flake graphite powder as raw material, because carbon or graphite powder purity is high, the effect of conductive graphite powder is better in smelting alloy steel, iron alloy, electrode graphite powder as raw material. The electrode produced, then the strong current through the melting zone, the arc electrode into the electric furnace, the electrical energy into heat, the temperature rises to 2000 degrees Celsius, so as to achieve the purpose of melting or reaction.

- Q: How do graphitized electrodes differentiate between high power and low power?

- Compared with other materials of graphite anode plate has high temperature resistance, good electrical and thermal conductivity, easy machining, good chemical stability, acid and alkali resistance, low ash content; for electrolytic solution, preparation of chlorine, caustic soda, salt alkali electrolytic solution preparation; application such as graphite anode plate can be used as conductive anode electrolytic salt solution preparation of caustic soda. Graphite anode plate can be used as conductive anode in electroplating industry. It is an ideal material for electroplating. It can make electroplating products have the advantages of smoothness, delicacy, wear resistance, corrosion resistance, high brightness and not easy to change color.

- Q: Graphitized anode, cathode and graphite electrode, respectively How can one differentiate and use differently?

- Compared with other materials of graphite anode plate has high temperature resistance, good electrical and thermal conductivity, easy machining, good chemical stability, acid and alkali resistance, low ash content; for electrolytic solution, preparation of chlorine, caustic soda, salt alkali electrolytic solution preparation; application such as graphite anode plate can be used as conductive anode electrolytic salt solution preparation of caustic soda. Graphite anode plate can be used as conductive anode in electroplating industry. It is an ideal material for electroplating. It can make electroplating products have the advantages of smoothness, delicacy, wear resistance, corrosion resistance, high brightness and not easy to change color.

- Q: How large is the permissible overload current per square millimeter of the graphite electrode cross section?

- Overhead wires, radiating the best conditions, allowed the current largest. The insulated wire in the house is laid in the wall, which has the worst heat release conditions and the smaller permissible current, so there are different safety currents.

Send your message to us

China Graphite Electrode Production - RP HD HP UHP Graphite Electrodes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords