High Anti-Corrosion Prime Prepainted Galvanized Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

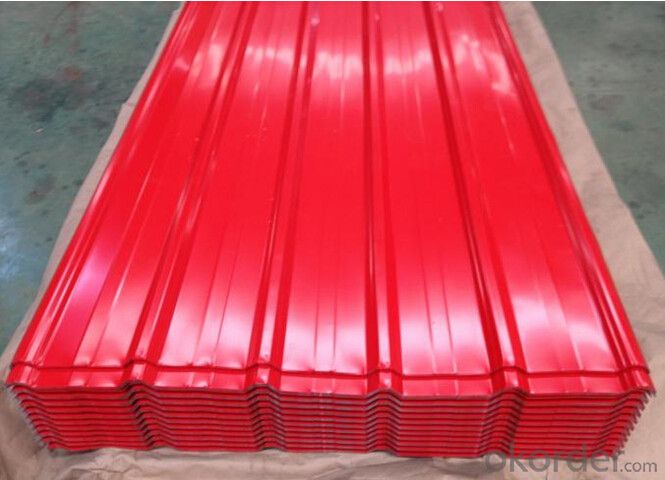

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils used in the production of kitchen appliances?

- Steel coils are used in the production of kitchen appliances as they are transformed into various components such as panels, frames, and structural elements. These coils are typically cut, shaped, and formed to create the necessary parts for appliances like refrigerators, ovens, and dishwashers. The high strength and durability of steel make it an ideal material for these appliances, ensuring their longevity and reliability.

- Q: How are steel coils used in the production of electrical appliances?

- Steel coils are used in the production of electrical appliances as the core material for transformers and motors. The coils are wound around an iron core to create electromagnetic fields that enable efficient energy transfer and power generation within these appliances.

- Q: I need a machine which can produce steel pipes, but I don't know where to look...If you want me to state dimensions etc. just say...Thanks :)

- Gary, Indiana. There's lots of old, unused steel forming equipment just laying around.

- Q: What are the common defects in steel coil surface finishes?

- Common defects in steel coil surface finishes include scratches, pits, roll marks, stains, and unevenness. These defects can be caused by various factors such as improper handling, processing issues, or equipment malfunction. These surface defects affect the aesthetics and quality of the steel coil, making it unsuitable for certain applications or requiring additional processing to rectify the defects.

- Q: Steel or stainless steel

- Steel often has impurities that can generate fumes, which cause a fever identical to smoke inhalation. You always need to be concerned about what you are breathing around hot metal.

- Q: What are the common surface treatments for steel coils?

- The common surface treatments for steel coils include galvanizing, painting, and coating with protective films.

- Q: I am doing a experiment on mild steel soaked in sodium chlorideanyone can enlighten me about the effect of the sodium chloride in engineering term ?The mild steel specimen which I soaked in the sodium chloride has orange rust on it

- The mild steel contains a lot of Iron. The NaCl solution quickly attacks the iron content and forms rust. Over time, the solution may also cause what is called 'Chloride Cracking' of the steel. Pitting corrosion of stainless steel due to chlorides would certainly produce a rust-colored product. Passivation can be used to maintain a good corrosion resistant surface of stainless steel process vessel. There are many commercial products for this purpose. In the pharmaceutical industry, this process is often called derouging, that is to remove the buildup of iron oxides on the stainless steel process surfaces

- Q: I'm going to see Man Of Steel this weekend, and the reviews that I've been hearing aren't that good. I've been hearing that it's this depressing, dark, dramatic film with no humor, loud noises, and action on top of action (which is kind of what I expected from this movie). With that said, I was quite positive that this was what the fans wanted, a more serious Super Man interpretation. I'm ultimately going to judge the movie when I see it, but for now, I have 3 short questions for you:1) What did you think of Man Of Steel?2) Superman Returns got somewhat better reviews than Man Of Steel. Does it seem logical?3) There is a huge fan battle between Man Of Steel and Christopher Reeve's version of Super Man. Which one do you favor?

- I loved the new interpretation in Man of Steel Superman Returns got very poor reviews in the beginning, and as the hatred has worn off and fans have been the only ones voting, the score has moved up. As fond as I am of Christopher Reeves, his version was a touch campy. I much prefer the serious treatment.

- Q: How are steel coils used in the manufacturing of chassis frames?

- Steel coils are used in the manufacturing of chassis frames by being cut and shaped into the desired dimensions and then welded together to create a strong and durable structure.

- Q: What are the different types of steel coil packaging methods?

- There are several different types of steel coil packaging methods, including but not limited to: strapping, wrapping, banding, shrink-wrapping, palletizing, and using steel coil covers or caps. Each method serves a specific purpose and provides varying levels of protection and stability during transportation and storage.

Send your message to us

High Anti-Corrosion Prime Prepainted Galvanized Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords