High Anti-Corrosion Color Coated Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Thickness: 0.3-0.8mm

2. Width: 914-1250mm

3. Inner Diameter: 508mm

4. Weight of Steel Coil: 3-15MT

5. Available Dipped Layer: 50-150g/m2

6. Surface Texture: Normal Coated

7. Type of coating structure: 2/1 Coat the top surface of the steel sheet twice, coat the bottom surface once, and bake the sheet twice.

8. Front side paint thickness: 15-25μm (bottome paint + top paint)

9. Back side paint thickness: 5-10μm

Mechanical Properties

1. Mechanical properties of base metals

Grade | Tensile Test | ||

Yield Strength MPa | Tensile Strength MPa | Elongation A80mm % ≥ | |

DC51D+AZ | 280-325 | 320-500 | 22 |

DC52D+AZ | 240-300 | 270-420 | 26 |

DC53D+AZ | 140-260 | 270-380 | 30 |

2. Common performance of front coating

(1). Thickness: ≥20μm

(2). Pencil Hardness: 2H

(3). 60° specular glossiness of coating: >60

(4). 180°bend: ≤3T

(5). Impact: ≥9J

(6). Salt Fog Resistant: ≥500h

(7). Color difference: <3ΔE

- Q: Can cold rolled galvanized steel coils be acid washed after oxidation?

- Hot rolling is made of slabs (mainly continuous billets) as raw materials. After heating, strips are made from roughing mills and finishing mills. From the last finishing mill stand out of the hot strip laminar cooling through to the set temperature, the coiling machine rolled strip steel roll cooled, according to the different needs of users with different finishing line (flat, straightening, transverse or longitudinal, inspection, weighing, packing and marking etc.) processing and become steel, flat steel product volume and slitting.

- Q: How are steel coils used in the production of steel handles?

- Steel coils are used in the production of steel handles by being processed and shaped into the desired handle design. The coils are uncoiled and fed into a machine where they are cut, bent, and formed to create the handle shape. The coils provide the raw material needed for the manufacturing process, ensuring the handles are strong, durable, and able to withstand the required usage.

- Q: What are the different types of steel alloys used in coil production?

- There are various types of steel alloys used in coil production, including carbon steel, stainless steel, alloy steel, and tool steel.

- Q: I saw this really pretty ring online and it was made of steel. Is this a good ring? If I were to wash my hands with it on, would it rust and turn my finger green?

- Steel rust is brown not green! Very much expected to be of one type of stainless steel, and you should have no problem.

- Q: How do steel coil manufacturers manage inventory?

- Steel coil manufacturers employ a variety of strategies and techniques to effectively manage their inventory, optimize production, minimize costs, and meet customer demands. The following are some commonly used practices: 1. Accurate demand forecasting: Steel coil manufacturers analyze market trends, historical sales data, and customer orders to accurately forecast future demand. This enables them to determine the necessary inventory levels and plan production accordingly. 2. Just-in-time (JIT) inventory: Many steel coil manufacturers adopt the JIT inventory system, which involves maintaining minimal inventory levels by receiving raw materials shortly before production and delivering finished goods immediately after. This approach reduces carrying costs and mitigates the risk of excess inventory. 3. Collaborating with suppliers: Effective inventory management relies on close collaboration with suppliers. Steel coil manufacturers work closely with their suppliers to ensure timely delivery of raw materials, monitor quality, and maintain a consistent supply. Regular communication and sharing of production forecasts help suppliers plan their inventory accordingly. 4. Safety stock: Steel coil manufacturers maintain a certain level of safety stock to account for unpredictable fluctuations in demand, disruptions in the supply chain, or delays in raw material deliveries. This acts as a buffer to prevent stockouts and maintain customer satisfaction. 5. Implementing inventory control systems: Steel coil manufacturers utilize modern inventory control systems, such as Enterprise Resource Planning (ERP) software, to track inventory levels, monitor stock movements, and automate various inventory management processes. These systems provide real-time data and analytics, facilitating better decision-making and improving inventory accuracy. 6. Streamlining production planning: Steel coil manufacturers optimize production planning to minimize inventory holding costs. They schedule production based on demand forecasts, prioritize orders, and strive for efficient production runs to reduce setup times and material waste. 7. Regular inventory analysis: Steel coil manufacturers regularly analyze their inventory data to identify slow-moving items, obsolete stock, or excess inventory. By identifying such issues, they can take corrective actions such as offering discounts, initiating sales promotions, or adjusting production schedules to prevent inventory buildup. In conclusion, effective inventory management is crucial for steel coil manufacturers to maintain a lean and efficient operation while meeting customer demands. By utilizing these strategies, manufacturers can strike a balance between supply and demand, reduce costs, and enhance customer satisfaction.

- Q: Can anyone tell me what that means. I have seen it on knife blades an such. I am assuming it's a formula for the strength of the metal. who does that scale work, and please keep it simple.

- 440 is an AISI (American Iron and Steel Institute) material specification. It specifies the precise quantities of carbon and other elements present in the alloy. Here are the constituents of AISI 440 steel: Carbon - 0.6 to 0.75% Chromium - 16 to 18% Manganese - less than 1% Molybdenum - less than 0.75% Phosphorus - less than 0.04% Silicon - less than 1% Sulfur - less than 0.03% Iron makes up the remainder. AISI 440 is a heat-treatable, precipitation-hardening stainless steel.

- Q: How are steel coils inspected for chemical composition?

- The chemical composition of steel coils is examined using spectroscopy, a process that involves the utilization of a spectrometer. This instrument analyzes the light emitted or absorbed by a sample to determine its chemical makeup. Normally, a small portion of the coil is taken and prepared for analysis in the case of steel coils. This portion is then placed in the spectrometer, where a beam of light is emitted onto it. The light interacts with the atoms and molecules in the sample, causing specific wavelengths of light to be emitted or absorbed. The spectrometer measures the intensity of the emitted or absorbed light at different wavelengths and generates a spectrum, which is essentially a distinct fingerprint for the sample. This spectrum is then compared to a database of known spectra for various elements and compounds to ascertain the chemical composition of the steel. Through spectroscopic analysis, the presence and concentration of different elements like carbon, manganese, phosphorus, sulfur, and other trace elements in the steel can be identified. These elements have a significant impact on the steel's properties, strength, and suitability for different applications. Ensuring that the steel complies with the required specifications and standards, inspection for chemical composition is crucial in the steel industry. Any deviation from the desired chemical composition can potentially compromise the steel's performance and result in structural failures or other defects. In conclusion, spectroscopy offers a highly precise and dependable method for examining the chemical composition of steel coils. This aids in maintaining the quality and integrity of the steel products.

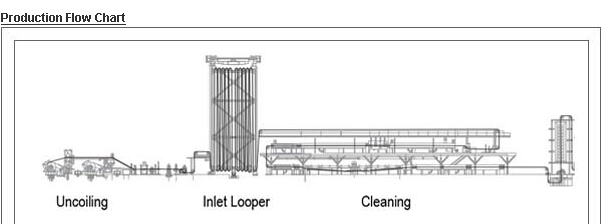

- Q: How are steel coils manufactured?

- Steel coils are manufactured through a series of processes that involve the transformation of raw materials into the final product. The manufacturing process begins with the extraction of iron ore, which is then smelted in a blast furnace to produce pig iron. The pig iron is further refined in a basic oxygen furnace to remove impurities and adjust the carbon content. Once the molten steel is obtained, it is continuously cast into large slabs or billets. These slabs are then rolled into thinner sheets or strips through a process called hot rolling. This involves passing the steel through a series of high-pressure rollers, which reduce the thickness and shape the material to the desired dimensions. During this process, the steel is also treated to improve its mechanical properties, such as strength and hardness. After hot rolling, the steel is pickled and cleaned to remove any scale or impurities on the surface. It is then cold rolled to further reduce the thickness and improve the surface finish. Cold rolling involves passing the steel through a set of rollers at room temperature, which increases its strength and dimensional accuracy. To form steel coils, the cold-rolled steel is typically wound tightly into a large coil shape. This is achieved by feeding the steel strip through a series of rollers that gradually wind it into a spiral. The coils are then typically annealed to relieve internal stresses and improve the material's formability. Finally, the steel coils are coated or treated, depending on their intended use. This can involve applying a protective coating, such as zinc or paint, to enhance corrosion resistance or providing a specific surface treatment for improved adhesion in subsequent processes. Overall, the manufacturing of steel coils is a complex process that involves several stages, including smelting, casting, hot rolling, cold rolling, coiling, and surface treatment. Each step contributes to the final product's quality and properties, ensuring that steel coils meet the required specifications for various industrial applications.

- Q: How are steel coils used in the production of structural steel?

- Steel coils are used in the production of structural steel by being unwound and processed through various manufacturing techniques, such as rolling and shaping, to create different structural components like beams, columns, and plates.

- Q: A steel rod AISI 1040 has the ultimate tensile strength Sut of 113 kpsi. Determine the rotating bending specimen's endurance limit S'e at 10 to the 6th cycles.

- Aisi 1040

Send your message to us

High Anti-Corrosion Color Coated Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords