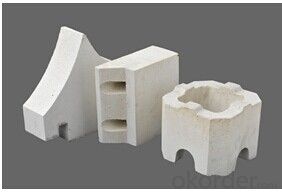

High Alumina Sillimanite Fire Brick for Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Resistance to corrosion and erosion;

2.Least contamination for molten glass;

3.Improve the productivityaa

4.Long life

Features:

The sillimanite brick is made of sillimanite minerals.After high temperature calcination,it become mullite and

dissociate silicon dioxide.Generally use high-temperature firing method and slurry casting method to produce.

1.Good thermal stability.

2.Strong resistance to chemical attack.

3.It is the first choice of stable material for glass forming.

Applications:

1.Widely used in glass furnace,such as regenerator arch.

2.Mainly used in the blast furnace.

3.

Sillimanite brick physiochemical index:

Item | Properties | ||||||

Sillimanite | Andalusite | Cordierite and mullite | Pouring sillimanite | ||||

LS-65 | L-60 | H-60 | HS-55 | SPCD-50 | SPCD-60 | CS-58 | |

AL2O3(%) | 65 | 60 | 60 | 55 | 50 | 60 | 58 |

Fe2O3(%) |

|

|

|

|

|

| 0.8 |

Refractoriness,°C | 1790 | 1790 | 1790 | 1770 | 1770 | 1790 | 1790 |

Apparent porosity % | 22 | 22 | 22 | 22 | 24 | 24 | 26 |

Cold Crushing strength MPa | 50 | 50 | 40 | 40 | 40 | 50 | 50 |

Bulk density,g/cm3 | 2.2 | 2.2 | 2.5-2.7 | 2.5-2.7 | 2.4 | 2.4 | 2.2 |

Softening temperature under load,KD°C≥ | 1550 | 1500 | 1500 | 1450 | 1450 | 1500 | 1450 |

Permanent linear change,%(°C×h) | ±0.2 | ±0.2 | ±0.2 | ±0.2 | (1000°C)≤±0.5% | (1000°C)≤±0.5% | 1400°C×2h +0.1 -0.3 |

Application | Used for temperature change severe industrial furnace and thermal lining equipment | All sorts of kiln burner brick and ceramic kiln brick | All industrial furnace | ||||

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- All the raw materials adding order, mixing time, material and material moisture trapped. 4, the pressure and the volume density of Pei brick and brick Pei size etc..

- Q: What is the density of a super high alumina brick and what is the price?

- Super high alumina brick, alumina content of 80% bricks, bulk density of 2.7g/cm3 or more, the factory price of about 1900 yuan

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: What are the alloy wear resistance materials?

- According to the composition of Beijing Naimo metal materials company will wear resistant metal materials is divided into the following five categories: one: high manganese steel series: high manganese steel (ZGMn13),

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q: What does refractory consist of?

- According to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Before making bricks, the raw materials are usually tested and tested to see if the aluminum content is up to standard

- Q: How high can aluminum bricks expand at 80O degrees of heat?

- The expansion of high alumina brick is not only related to temperature, but also related to its material composition. The refractory temperature of high alumina brick is above 1770 centigrade. The temperature of 800 DEG C has little influence on the expansion of high alumina brick.

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- When the high alumina brick is used at high temperature, the physical and chemical indexes and other constants will not change if the temperature is in the physical and chemical indexes and the softening temperature of the load.

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- Because the hot air outlet of the top burning hot blast furnace is high, the installation requirement of the hot air manifold is high, and the requirement of the strength of the pillar structure is higher, so the rectangular arrangement of the hot blast stove is arranged. The top burning hot blast stove is located on the furnace top because of burner and hot air valve,Therefore, operation, maintenance and installation all require mechanization and automation. Also, because these water cooled valves are mounted with a high elevation,Therefore, the demand for cooling water supply pressure should be improved accordingly, the use of large top burning hot blast stove, the key lies in the design of high-power high-efficiency short flame burner. The top combustion hot blast furnace absorbs the advantages of internal combustion and external combustion hot blast stoves, and overcomes some of their shortcomings,Its structure can meet the requirements of modern blast furnace for high temperature, high pressure and large scale development,Combustion capacity, while meeting production requirements, has been successfully reduced by many devices,

Send your message to us

High Alumina Sillimanite Fire Brick for Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords