High Alumina Refractory Brick for Cement Kilns with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Brick for Cement Kilns with Good Price

1.Description

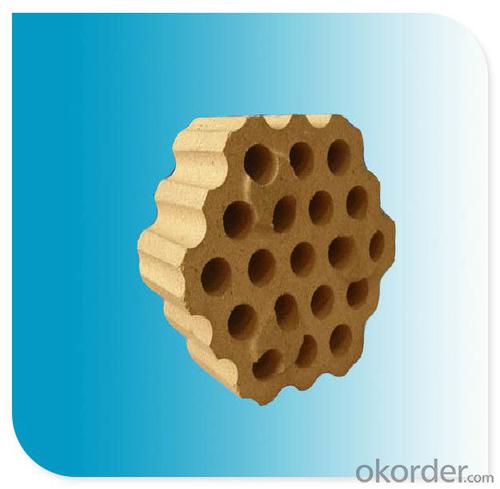

Products | Spalling Resistant High Alumina Bricks(refractory bricks for cement kiln) |

Applications | Preheating & decomposition Zone of Rotary Kiln |

Features | 1,Good performance of anti alkali erosion resulted from raw material and fuel |

2,Good thermal shock resistance | |

3,High mechanical resistance | |

4,Low porosity | |

5,low thermal conductivity |

Index Products | Spalling Resistant High Alumina Bricks | |

Al2O3 | % | ≥70 |

Fe2o3 | % | / |

Bulk Density | g/cm3 | ≥2.5 |

Apparent Porosity | % | ≥23 |

Refractoriness under Load(0.2MPa) | ℃ | ≥1470 |

Cold Crushing Strength | Mpa | ≥70 |

Thermal Shock(1100℃,water cooling) | times | ≥25 |

Feature:

1.High compression strength.

2.Top high-temperature capability.

3.Excellent thermal stability.

4.Low thermal conductivity.

5.Powerful penetrating-proof capability.

6.Good erosion-resistance.

7.Long service life.

Application:

Refracory brick plant can be in direct contact with the flame,this insulating brick can be used as linings or as thermal preservation layers in various industrial furnaces and kilns in metallurgical industry, ceramic industry, chemical industry, machinery industry.

such as blast furnace, hot blast stoves ,electric arc furnace, cement kiln,melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other thermal industrial equipment.

FAQ

1. Do you provide samples?

Yes, samples are free. Guarantee samples quality same as mass production quality.

2. What's the MOQ of trial order?

No limit,We can offer the best suggestions and solutions according to your condition.

3. Can we visit your company?

Of course,welcome at any time,seeing is believing.

4. Do you accept OEM?

Yes, we can do OEM.

5. What are the payment terms?

Usually T/T, D/A, D/P, L/C, Western Union ,others could be discussed .

6. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

7. How are your products’ quality?

More than 20 years of production experience. The products will be strictly inspected before shipment, so the quality could be guaranteed.

8. How to slove the quality problems?

If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

9. What is the service life of your bricks?

The service life of different bricks is unlike.It also depends on your using condition and method.

10. How about your company's certification?

ISO9001 and Test Report,also we could apply other necessary certification.

11. How about your price?

Quality will be guaranteed. Competitive prices based on same quality.

Our services:

1.Adhering to the business philosophy "Mutual Trust, Mutual Benefit, Mutual Profit, Faith Oriented".

2.According to your requirements to produce your order and OEM/ODM service is available.

3.Products are inspected through SGS and BV etc and accord with the international standard.

4.Your inquiry related to our products or prices will be replied in a timely manner.

- Q: Introduction of high alumina brick

- Three alumina silicate refractory product with a content of two Al2O3 (48%).

- Q: What refractory material does cupola lining use?

- A class of inorganic nonmetallic materials with a refractoriness of not less than 1580 degrees. Refractoriness is defined as the temperature of a sample of a refractory cone sample that resists high temperature without loading and does not soften and melt down. But only in terms of fire resistance can not be fully described refractories, 1580 degrees of temperature is not absolute.

- Q: What is the price of the latest thermal insulation material?

- There are many kinds of insulation materials, and the price will fluctuate with the market. Small quantities of inquiry or procurement, then go directly to the local thermal insulation market, a wide variety of prices are basically the market price.

- Q: What are the specific raw materials for plastic pallets?

- There are two kinds of raw materials for plastic pallets: one is polypropylene (PP) and the other is polyethylene (HDPE).Plastic pallets for logistics storage: pp+pe material, recycled material 10%;Plastic trays for food trays: food grade PP, PE, pc;Polyethylene (HDPE) has excellent impact resistance and cold resistance, and it can resist environmental stress cracking. Excellent chemical stability, good oil resistance. Water absorption and tiny, low permeability, organic vapor transmission rate is larger. Electrical insulation is good, in all frequency range, dielectric properties are extremely excellent.

- Q: What is the price of the first grade high alumina brick?

- The specifications and different prices, relatively large fluctuations of the main push of the refractory Dongxin high alumina brick high alumina brick prices generally around 3000 have various levels of Dongxin refractories

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- In the meantime, the free silica content of silicon brick is as high as 90% above. Therefore, the most serious damage is silicon brick, followed by clay brick, high alumina brick, magnesia brick and so on.

- Q: Can high alumina brick resist carburizing?

- The key is to look at the content of Fe3O2 metal oxides (so-called anti carburizing brick generally refers to the content of Fe3O2 less than 1% clay brick and Gao Lvzhuan) just a photo shoot, out for everyone to see, high alumina brick common in reductive atmosphere has been chalking up.

- Q: What are the high temperature refractory mortars made of?

- Siliceous mud, mineral composition and chemical composition is similar with silica, excellent corrosion resistance, water glass slurry, drying shrinkage, but also can be used for bonding fiber products, sealing furnace wall.

- Q: How high can aluminum bricks expand at 80O degrees of heat?

- The expansion of high alumina brick is not only related to temperature, but also related to its material composition. The refractory temperature of high alumina brick is above 1770 centigrade. The temperature of 800 DEG C has little influence on the expansion of high alumina brick.

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The current configuration of domestic calcining active lime rotary kiln refractories are as follows: the discharge end of low cement high alumina castable with 3% steel fiber; the cooling zone and the firing zone: dry magnesia spinel brick with high aluminum brick with high temperature; preheating: high alumina brick; low temperature preheating zone: clay brick light clay brick; feeding end: low cement high alumina castable with 3% steel fiber; in addition, brick size also have the corresponding requirements; dimensional tolerances: dimensional tolerances used in different parts of the requirements are not the same, the general control in 2mm; corner damage: general permit edge damage 40mm and 5mm deep within angle loss in the hot and cold surface is allowed to have only one, three edges and the length of not more than 50mm; there are cracks parallel to the use of surface crack is not allowed, cracks of brick surface are allowed.

Send your message to us

High Alumina Refractory Brick for Cement Kilns with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords