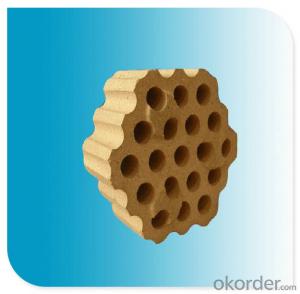

High Alumina Brick for Cement Kiln High Refractoriness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Refractoriness Brick for Cement Kiln

Specifications:

Use for Transition Zone and Cooling Zone

VDZ STANDARD,ISO STANDARD

Brand Index | CNBM001 |

SiC | 6-10 |

Al2O3 | ≥ 70 |

Cold Crushing strength Mpa≥ | 110 |

Apparent Porosity %≤ | 18 |

Bulk Density g/cm3≥ | 2.70 |

Refractoriness Under Load(°c ) | ≥ 1680 |

Features:

1. Low thermal conductivity, good thermal insulation performance.

2. Long service life, easy operation, could be shaped freely

3. Product specification: standard form, normal standard, shaped and special shaped bricks.

4. Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the most widely used.

Application:

Refracory brick plant can be in direct contact with the flame,this insulating brick can be used as linings or as thermal preservation layers in various industrial furnaces and kilns in metallurgical industry, ceramic industry, chemical industry, machinery industry.

such as blast furnace, hot blast stoves ,electric arc furnace, cement kiln,melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other thermal industrial equipment.

FAQ

1. Do you provide samples?

Yes, samples are free. Guarantee samples quality same as mass production quality.

2. What's the MOQ of trial order?

No limit,We can offer the best suggestions and solutions according to your condition.

3. Can we visit your company?

Of course,welcome at any time,seeing is believing.

4. Do you accept OEM?

Yes, we can do OEM.

5. What are the payment terms?

Usually T/T, D/A, D/P, L/C, Western Union ,others could be discussed .

6. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

7. How are your products’ quality?

More than 20 years of production experience. The products will be strictly inspected before shipment, so the quality could be guaranteed.

8. How to slove the quality problems?

If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

9. What is the service life of your bricks?

The service life of different bricks is unlike.It also depends on your using condition and method.

10. How about your company's certification?

ISO9001 and Test Report,also we could apply other necessary certification.

11. How about your price?

Quality will be guaranteed. Competitive prices based on same quality.

- Q: What are the high aluminum bricks made of?

- We specialize in the production of various LeiBao refractory refractory material, such as corundum, zirconia products, alumina hollow ball products, mullite products and so on.

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- In the course of the production of lime kiln, the local block of refractory brick is a very dangerous signal. It is suggested that you stop the kiln to prevent the collapse of a large area. Lime kiln is the main equipment for the production of limestone kiln and rotary kiln is two, with the growth of calcium carbide lime kiln industry, iron and steel industry, the construction industry to the amount of limestone has become the main production equipment, and refractory bricks became the heart of lime kiln.

- Q: What are the requirements for Rubble backfill height?

- Backfill should be filled with large stones, big face, small face upward, the decoration is stable, and then use small stones leveling, the gap between the stones can be swept into the slag, gravel, so that the gap filled.

- Q: The difference between aluminium refractory and magnesia refractory

- Therefore, the difference between the two is a neutral, one is alkaline, the original product is different naturally.

- Q: How to make refractory bricks and boiler wall adhesion more firm?

- If the condition, the user heat-resistant steel welding grip nails, expansion joints can not be too big.. Also to use high temperature aluminum brick, high temperature resistance, but also to extend its use cycle.

- Q: What are the alloy wear resistance materials?

- Alloy wear-resistant materials from different manufacturers different components in Beijing Naimo company as an example, the following alloy wear resistant material:1: Ni Cr alloy wear-resistant material2: chrome carbide wear-resistant material3: high manganese alloy wear-resistant material4: tungsten carbide alloy wear-resistant material5: nickel tungsten alloy wear-resistant material

- Q: What's the weight of the refractory bricks?

- Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick, refractory insulating bricks (Rong Zhuzhuan);

- Q: What causes breakage of refractory bricks?

- There are many factors that lead to the damage of refractory brick, can be divided into: the chemical loss (e.g. salt penetration, redox phenomenon), heat loss (burning, thermal shock), mechanical loss (kiln deformation, thrust, brick masonry quality etc.).

- Q: Use of high alumina refractory bricks?

- High alumina refractory brick in Al2O3 more, close to neutral refractory material, can resist acid slag and alkaline slag erosion, because it contains SiO2, so alkaline slag ability than acid resistance slag ability less.It is widely used in building blast furnace, hot blast furnace, furnace top, blast furnace, reverberatory furnace and rotary kiln lining. In addition, high alumina bricks are widely used as furnace regenerative checker, pouring system for plug nozzle, etc..

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The current configuration of domestic calcining active lime rotary kiln refractories are as follows: the discharge end of low cement high alumina castable with 3% steel fiber; the cooling zone and the firing zone: dry magnesia spinel brick with high aluminum brick with high temperature; preheating: high alumina brick; low temperature preheating zone: clay brick light clay brick; feeding end: low cement high alumina castable with 3% steel fiber; in addition, brick size also have the corresponding requirements; dimensional tolerances: dimensional tolerances used in different parts of the requirements are not the same, the general control in 2mm; corner damage: general permit edge damage 40mm and 5mm deep within angle loss in the hot and cold surface is allowed to have only one, three edges and the length of not more than 50mm; there are cracks parallel to the use of surface crack is not allowed, cracks of brick surface are allowed.

Send your message to us

High Alumina Brick for Cement Kiln High Refractoriness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords