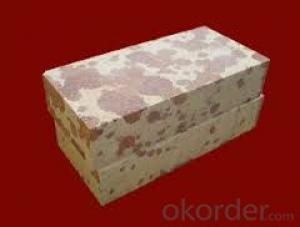

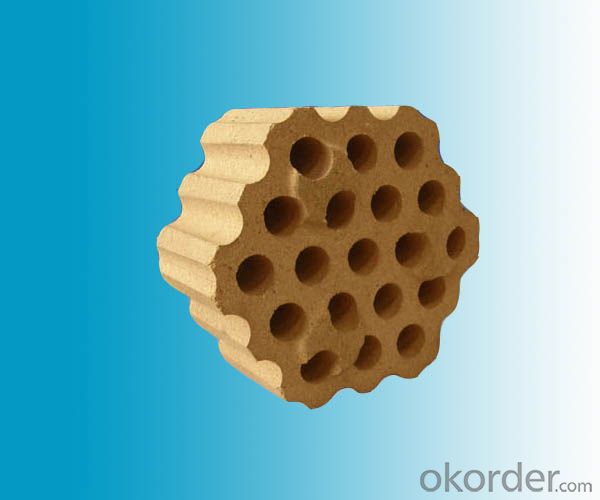

High Alumina Refractory Brick for Cement Kiln Copper Aluminum Melting Induction Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Alumina Refractory Brick for Cement Kiln Copper Aluminum Melting Induction Furnace

Company profile:CNBM internation MATERIAL CO., LTD is the specialized manufacturer and supplier of refractory in China, Our products mainly include refractory bricks, refractory castable, refractory precast shape, insulating brick etc. For refractory castable and precast shape they are very popular in the Europe, North American area.

Index | LZ-48 | LZ-55 | LZ-65 | LZ-75 | LZ-80 | LZ-85 | |

Al2O3 % | ≥48 | ≥55 | ≥65 | ≥75 | ≥80 | ≥85 | |

Fe2O3 % | ≤2.5 | ≤2.5 | ≤2.0 | ≤2.0 | ≤2.0 | ≤1.8 | |

Refractoriness °C | 1760 | 1760 | 1770 | 1770 | 1790 | 1790 | |

Apparent porosity % | ≤23 | ≤23 | ≤23 | ≤23 | ≤22 | ≤22 | |

Refractoriness under load 0.2MPa°C | 1420 | 1470 | 1500 | 1520 | 1530 | 1550 | |

Cold crushing strength MPa | 45 | 45 | 50 | 60 | 65 | 70 | |

Permanent linear chang % | 1500°C×2h | +0.1~0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | |

1450°C×2h | +0.1~-0.4 | ||||||

Our services:

1.Adhering to the business philosophy "Mutual Trust, Mutual Benefit, Mutual Profit, Faith Oriented".

2.According to your requirements to produce your order and OEM/ODM service is available.

3.Products are inspected through SGS and BV etc and accord with the international standard.

4.Your inquiry related to our products or prices will be replied in a timely manner.

Application:

Refracory brick plant can be in direct contact with the flame,this insulating brick can be used as linings or as thermal preservation layers in various industrial furnaces and kilns in metallurgical industry, ceramic industry, chemical industry, machinery industry.

such as blast furnace, hot blast stoves ,electric arc furnace, cement kiln,melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other thermal industrial equipment.

FAQ

1. Do you provide samples?

Yes, samples are free. Guarantee samples quality same as mass production quality.

2. What's the MOQ of trial order?

No limit,We can offer the best suggestions and solutions according to your condition.

3. Can we visit your company?

Of course,welcome at any time,seeing is believing.

4. Do you accept OEM?

Yes, we can do OEM.

5. What are the payment terms?

Usually T/T, D/A, D/P, L/C, Western Union ,others could be discussed .

6. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

7. How are your products’ quality?

More than 20 years of production experience. The products will be strictly inspected before shipment, so the quality could be guaranteed.

8. How to slove the quality problems?

If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

9. What is the service life of your bricks?

The service life of different bricks is unlike.It also depends on your using condition and method.

10. How about your company's certification?

ISO9001 and Test Report,also we could apply other necessary certification.

11. How about your price?

Quality will be guaranteed. Competitive prices based on same quality.

- Q: What are the specific raw materials for plastic pallets?

- With excellent mechanical properties, its strength and elasticity are higher than HDPE, and it has good flexural fatigue resistance. It has good heat resistance and good chemical stability. Besides being concentrated by concentrated sulfuric acid and concentrated nitric acid, it is relatively stable to other chemical reagents. The high frequency insulation performance of polypropylene is excellent because of its almost no water absorption, so the insulation performance is not affected by temperature.

- Q: Density of high alumina bricks

- The density of high alumina bricks is determined according to the price. The average density is between 2.3-2.5g/cm3. The higher the density, the higher the price, the higher the aluminum bricks are in the industry. More than 2.4 are required.

- Q: How are the high alumina bricks fired?

- Generally, the high alumina bauxite is added with a small amount of clay. After being ground, the gas is injected and shaped in the form of slurry by the way of gas attack or foam, and it is burnt at 1300~1500 DEG C. Sometimes industrial alumina can be used to replace part of bauxite clinker. Used for lining and thermal insulation of masonry kilns, as well as for areas where there is no high temperature, high melting material erosion and erosion effects. When touching the flame directly, the touch temperature shall not be higher than 1350 degrees.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- The T3 in T3 refractory bricks refers to the model indicating that the refractory brick model is T-3, and that the corresponding T-3 model is 230*114*65 (mm)

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- Refractory powders are not rich in free silica in varying degrees

- Q: What are the characteristics of high alumina bricks?

- High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining. High R.U.L, low creep high alumina brick with high grade bauxite, fused corundum, fused mullite as main raw material of high-grade refractory materials.

- Q: What are the requirements for refractory materials in heat treatment furnace?

- Fire resistance is an important performance index of refractory materials, but it does not represent the highest temperature in actual use of refractory materials. In actual use, refractories also bear certain pressure, therefore, must consider the high strength at high temperature refractory material, which is in high temperature under certain pressure without deformation, such as the NZ-40 refractory refractory degree up to 1730 DEG C, but the maximum temperature is only 1350 degrees celsius.

- Q: What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- When the high alumina brick is used at high temperature, the physical and chemical indexes and other constants will not change if the temperature is in the physical and chemical indexes and the softening temperature of the load.

- Q: What are the categories of bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels.

Send your message to us

High Alumina Refractory Brick for Cement Kiln Copper Aluminum Melting Induction Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords