High Alumina Refractory Bricks for Induction Melting Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

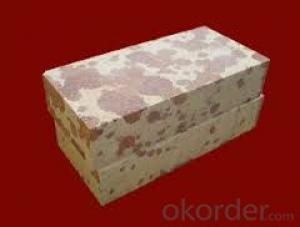

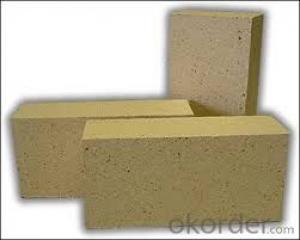

Alumina bricks are made from bauxite of super quality, bonding chamotte and additives. The main Al203 content is 48%-99%. The advantages of high alumina bricks are high refractoriness, anti alkaline/acid erosions, good strength under high temperature and good thermal shock resistance. High alumina bricks were widely accepted in thermal equipment of metallurgy, petroleum, chemical industry, construction materials, machinery and militaries etc.

Various Grades Products for Your Different Industries & Furnaces

High Alimina Bricks for blast furnaces

Corundum Mullite Bricks For Blast Furnaces

Mullite Bricks for Blast Furnaces

High alumina bricks for hot blast furnaces

Low Creeping High Alumina Bricks series for Hot Blast Stove

Low Creeping Andalusite Bricks for Hot Blast Stove

Low Creeping and Anti-Thermal Shock Alumina Bricks for Hot Blast Furnaces

High Alumina Bricks for Blast Stove Burner

High Alumina Bricks for EAF Roof

High Alumina Bricks for Ladles

Anti-Spalling High Alumina Bricks for Cement Kilns

Unfired High Alumina Bricks for Cement Kilns

High Alumina Bricks for General Uses

Good Price & Fast Delivery & OEM Service

Usually we can finish the production within 30 days. Some stardard products we have stocks in China or abroad which can make the delivery time very fast and short.

We supply not only the standard size products, we also produce basing customers' drawings, after we check your furnace application and drawings, we will give you the most cost efficient solutions.

Long Life Span and Best After-sales Serivice.

Our advanced production equipment and good educated workers & most strict quality control process make sure the best quality bricks to be made from our production lines. We also supply good technical support after sales and grow together with our customers.

Specification:

Item Specifications | LZ-48 | LZ-55 | LZ-65 | LZ-75 | LZ-80 | LZ-85 | |

Al2O3 % | ≥48 | ≥55 | ≥65 | ≥75 | ≥80 | ≥85 | |

Fe2O3 % | ≤2.5 | ≤2.5 | ≤2.0 | ≤2.0 | ≤2.0 | ≤1.8 | |

Refractoriness°C | 1760 | 1760 | 1770 | 1770 | 1790 | 1790 | |

Bulk Density≥ g/cm3 | 2.30 | 2.35 | 2.40 | 2.45 | 2.63 | 2.75 | |

Apparent porosity % | ≤23 | ≤23 | ≤23 | ≤23 | ≤22 | ≤22 | |

Refractoriness under load 0.2MPa°C | 1420 | 1470 | 1500 | 1520 | 1530 | 1550 | |

Cold crushing strength MPa | 45 | 45 | 50 | 60 | 65 | 70 | |

Permanent linear chang % | 1500°C×2h | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 |

why us

1. We are a manufacturer, which can control the cost easilier than trade company also can give you anwer more quickly.

2. As a manufacturer, we know much in technique and can give you more support in technique problem.

3.We establish the company and began to produce refractory materials since 1988. We have longtime and mature experience for entire production.

4.Our products are complete in specifications with various of sizes.

5. We enjoy a good reputation in the customers in domestic and overseas markets.

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- Therefore, the choice and masonry of refractory bricks are of vital importance. If there is a brick kiln kiln off block process of reproduction, is now because of the use of refractory brick kiln material mostly three grade high alumina bricks. The content of AL2O3 is about 55%, of which the content of Fe2O3 is about 2%, which is weak, and the alkali corrosion resistance is a little worse. In a containing three grade high alumina bricks in the composition of AL2O3, Si2O3, and other elements also contain K, Na trace, were the most, thus causing the system of the low melting point is very low, even at 1400 DEG C has been liquid phase, and generate CaAL12O19 limestone and calcium feldspar etc.. Form corrosion loss. Therefore, a long time will cause the loss of block. On the one hand, it may be caused by construction.

- Q: What is the difference between corundum and high alumina??

- The main component of high purity 99 corundum brick is corundum sand,90 corundum brick is mainly composed of corundum sand and a small amount of Suzhou soil, mullite.

- Q: What are the common thermal insulation materials for thermal conductivity?

- The single organic insulation material should be the best polyurethane in the field. In accordance with the production process can be divided into on-site foam polyurethane and factory prefabricated rigid foam polyurethane board. The scene is polyurethane foam isocyanate and polyol to cool (polyether or polyester) two components as the main raw materials with additives, the on-site spraying construction with thermal insulation and waterproof function of the rigid foam material.

- Q: How to make refractory bricks and boiler wall adhesion more firm?

- If the condition, the user heat-resistant steel welding grip nails, expansion joints can not be too big.. Also to use high temperature aluminum brick, high temperature resistance, but also to extend its use cycle.

- Q: What are the alloy wear resistance materials?

- According to the composition of Beijing Naimo metal materials company will wear resistant metal materials is divided into the following five categories: one: high manganese steel series: high manganese steel (ZGMn13),

- Q: Which is better, the soft core or the hard core?

- The wire has two kinds of hard core and soft core, the hard core line is only one wire core, and the soft core line has a plurality of wire cores. For the same sectional area, the 7 core is more than the more than 30 core. There is a difference in use. Generally used for DC is the use of hard core line, because of its small line consumption; and for communication, we should use soft core line, but also in order to reduce its line consumption

- Q: How to distinguish the good or bad of the high aluminum brick?

- In the procurement of high alumina brick, the first color, high quality aluminum brick, brick surface smooth, yellow color pale, four sides equal, no broken angle, no cracks.

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Before making bricks, the raw materials are usually tested and tested to see if the aluminum content is up to standard

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- The gas will directly lead the dome combustion, in order to ensure good mixing, complete combustion of gas and air in a short time, the combustion capacity of short flame or flameless combustion burner, commonly used for semi jet short flame burner.

- Q: The difference between clay bricks and clay bricks

- Sintering bricks do not have clay bricks, so sintering bricks are made of stone. Clay brick is clay cooking, two yo, qualitative difference, but the appearance and color almost, but the quality is very different, life expectancy is also a great gap.

Send your message to us

High Alumina Refractory Bricks for Induction Melting Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords