High Alumina Lightweight Insulation Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | High alumina fire brick light weight insulation refractory brick 1 Fumigated pallet 2 A stable stack of bricks 3 Lables on two opposite faces 4 Card edges 5 Steel or nylon bands 6 Plastic wrap 7 Overall dimension:1.0*1.0*1.0m (Routine) 8 Gross weight:0.6-1.0MT (Routine) |

| Delivery Detail: | 30 days after order |

Specifications

High alumina insulating bricks are ideal products for application of service temp. below 1400deg.

Product Description

High alumina fire brick light weight insulation refractory brick

Featured with uniform structure, high crushing strength, low thermal conductivity, good high-temp. volume stability, high alumina insulating bricks are ideal products for application of service temp. below 1400°C, and widely used as inner lining or insulating layer in metallurgy, ceramic, petrochemical and machinery industries.

The following are technical specifications:

| Brand | PLG-1.3 | PLG-1.0 | PLG-0.9 | PLG-0.8 | PLG-0.7 | PLG-0.6 | PLG-0.5 |

| Bulk density, (g/cm3)≤ | 1.3 | 1.0 | 0.9 | 0.8 | 0.7 | 0.6 | 0.5 |

| Cold crushing strength, (MPa)≥ | 7.5 | 4.5 | 4.0 | 3.5 | 2.5 | 2.0 | 1.5 |

| Linear change on heating, ≤2% (°C×h) | 1400×12 | 1400×12 | 1400×12 | 1400×12 | 1350×12 | 1300×12 | 1250×12 |

| Thermal conductivity,(W/m.k) ≤ [350±25°C] | 0.38 | 0.35 | 0.32 | 0.28 | 0.25 | 0.22 | 0.19 |

| Al2O3(%)≥ | 48.0 | ||||||

| Fe 2O3(%)≤ | 1.5 | ||||||

Our Services

♥ Research of application basis, new technical process and new technology, development of new product, and technical consultation.

♥ Optimum solution and product supply of refractories for high temperature industries, such as iron&steel, non-ferrous, petrochemical and building materials.

♥ Engineering design, contract and consult for refractories, and civil architecture design.

♥ Research,development, manufacture and sale of superhard materials.

♥ R&D, manufacture and sale of special packing materials for export.

♥ Inspection,supervision and arbitration of refractories.

♥ Consultation and services in refractories information.

♥ Training and cultivation of high-level talents in refractories profession.

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- According to my experience, two kinds of high alumina bricks from the index, there is a big difference between the content of AL2O3, a high aluminum brick in 75%, two grade high alumina bricks in 65%, so the content is not the same, also decided that the use of temperature difference, the difference is very big.

- Q: Introduction of high alumina brick

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3. If the content of Al2O3 is higher than 90%, it is called corundum brick. Because of the different resources, the standards of different countries are not identical. For example, European countries limit the content of Al2O3 to high alumina refractories by 42%. In China, the content of Al2O3 in high alumina brick is usually divided into three parts: I, etc. - Al2O3 content, >75%, II, etc. - Al2O3 content is 60 ~ 75%, and the content of Al2O3 is 48 ~ 60%.

- Q: What are the alloy wear resistance materials?

- KNMn19Cr2 (patent) high manganese alloy (ZGMn13Cr2MoRe), super high manganese alloy (ZGMn18Cr2MoRe); two: anti-wear chromium cast iron series: such as high, medium and low chromium alloy cast iron (Cr15MOZCu); three: wear resistant alloy steel series: such as, low and high carbon multi metal combined steel (such as ZG40SiMnCrMO and ZG35Cr2MoNiRe); four: ADI (ADI) series; five: all kinds of composite or gradient material and hard alloy materials, nano KN alloy (patent product): such as chromium carbide composite (Cr2C3+Q235), high-energy ion osmosized tungsten carbide materials (WCSP), high toughness of cemented carbide (YK25.6), KN999 nano alloy (Beijing Naimo patent) etc.;

- Q: What are the high temperature refractory mortars made of?

- Products used in metallurgy, building materials, machinery, chemical, power industry, industrial thermal furnace, for masonryBuilding clay brick, high alumina brick and corundum brick have the characteristics of full grey seam, good airtightness, high bonding strength, high temperature performance and suitable construction time

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Before making bricks, the raw materials are usually tested and tested to see if the aluminum content is up to standard

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Prolong the sintering time and adjust the aluminum content of the high alumina brick.

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- First of all, there is a difference in the material, one is clay, and one is high aluminum.Also known as clay brick brick, is a man-made small bulk building, clay brick clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting, solid and hollow.

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

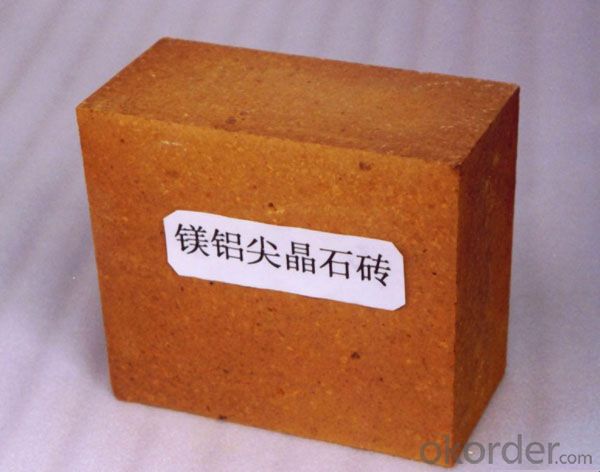

- The physical and chemical properties of refractory materials used in rotary kiln are as follows: physical and chemical properties of refractory materials used in rotary kilnMaterial name: high temperature compressive strength (MPa), softening temperature (DEG C), thermal shock resistance (1100 DEG C, cold water), sub volume density (g/cm3)Magnesia spinel brick is greater than or equal to 50 is greater than or equal to 1700 = 12 = 2.95High alumina brick is greater than or equal to 75 = 1520 = 8 = 2.57High aluminum bricks more than 50 = 1700 = 12 = 1The clay brick is greater than or equal to 30 = 1400 = 12 = 2.30

- Q: The difference between clay bricks and clay bricks

- Clay brick is a small building with artificial bulk. Also called sintered brick. Solid clay brick is one of the oldest building materials in the world. It is a building material that is loved by the people.

Send your message to us

High Alumina Lightweight Insulation Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords