High Alumina Corundum-Mullite Insulation Brick in Lightweight

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

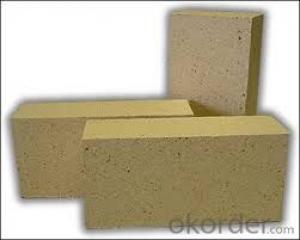

Description of Corundum-mullite Insulation Brick

Corundum-mullite Insulation Brick in Light Weight refers to containing AL2O3 30% ~ 46% of lightweight refractory products, clay clinker or light clinker and plastic clay as the main raw material, usually fuel production, but also can send or chemical foaming method porous structure. Common light chamotte bulk density of 0.75 ~ 1.2g / cm3, mainly for industrial kilns does not melt and no erosion of the contact action of gas insulation layer material, the using temperature of Corundum-mullite Insulation Brick is 1200 ~ 1400 ° C.

Specifications for Corundum-mullite Insulation Brick

Item | ZGN-42 | GN-42 |

AL2O3 /% | ≥42 | ≥42 |

Fe2O3 /% | ≤1.6 | ≤1.7 |

Refractoriness /°C | ≥1750 | ≥1750 |

Apparent porosity/ % | ≤15 | ≤16 |

Cold crushing strength/ Mpa | ≥58.8 | ≥49.0 |

Refractoriness under load/ °C | ≥1450 | ≥1430 |

Reheating Linear Change(1450°C,2h)/% | 0 -0.2(3h) | 0 -0.3(3h) |

Permeability | This test must be conducted.The data of the test shall be included in the quality certificate. | |

Features of Corundum-mullite Insulation Brick

Good volume stability at high temperature.

High-temperature creep rate is low.

Good thermal shock resistance.

Good corrosion resistance.

Good wear resistance.

Typical Application of Corundum-mullite Insulation Brick

Furnaces of metallurgy industry, heat treatment furnace.

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace .

- Q: What refractory material does cupola lining use?

- A class of inorganic nonmetallic materials with a refractoriness of not less than 1580 degrees. Refractoriness is defined as the temperature of a sample of a refractory cone sample that resists high temperature without loading and does not soften and melt down. But only in terms of fire resistance can not be fully described refractories, 1580 degrees of temperature is not absolute.

- Q: Application characteristics of high alumina brick

- Slag resistance. Due to the high alumina brick products in the three oxidation of two aluminum is neutral and high content, so this material products for acid-base slag corrosion resistance.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is a kind of refractory material in refractory brick products. It is made of refractory clay or other refractory material. It belongs to the product of Si Al System

- Q: How to reduce porosity of high alumina brick

- In order to reduce the porosity of high alumina brick, the corresponding measures should be taken from the selection of raw materials, batching, mixing, molding and firing.The water absorption rate of the first grade high alumina bauxite clinker should be less than 5%, and the water absorption rate of two grade high alumina material should be less than 7%. Fine grinding of soft clay and bauxite clinker with less than 4% water content. Mixed fine milling ingredients with this, can reduce the porosity of bricks.

- Q: What is spalling resistant high alumina brick?

- Using bauxite as main raw materials, the introduction of a small amount of ZrO2 (ZrO2 is due to phase transition, between monoclinic and tetragonal type can improve the thermal stability of the products), adding a certain amount of binder and additives, the particle size distribution control mud, forming and sintering of refractory products produced, called anti stripping high alumina brick.

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Prolong the sintering time and adjust the aluminum content of the high alumina brick.

- Q: Does the chimney have high acid resistance?

- The chimney particles and gases, mostly coal tar products, material acidic, therefore, take good acid resistance, acid proof brick, Grouts also used potassium silicate clay acid is preferred.

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- A neutral refractory with an alumina content of more than 48%. Made from alumina or other raw materials of high alumina content; formed and calcined. High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining.

- Q: What are the categories of bricks?

- Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

Send your message to us

High Alumina Corundum-Mullite Insulation Brick in Lightweight

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords