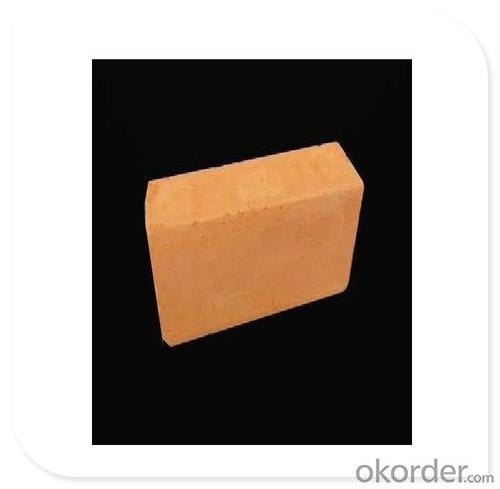

High Alumina Kiln Furnace Refractory Fire Clay Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Kiln Furnace Refractory Fire Clay Bricks

HOT PRODUCT:

Calcium Silicate Insulation Board 1000C

Calcium Silicate Pipe/2014 New Product/ Best Quality With Good Sale

Brands Blanket Heat Insulation blanket Thermal Insulation Refractory Ceramic Fiber Blanket

Wall Heat Insulation Rock Wool Board

Foam Glass Sound/ Fire Proof /Heat Insulation Materials

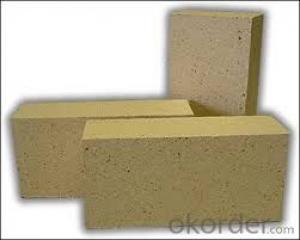

ITEM | XS-32 | XS-34 | XS-36 | XS-38 |

Al2O3(%)Min | 35 | 38 | 48 | 65 |

Fe2O3(%)Max | 3.00-4.00 | 2.50 | 2.00 | 2.00 |

0.2Mpa Refractoriness under load (°C) Min | 1300 |

1350

|

1450

|

1500

|

Apparent porosity(%) | 22-26 | 20-24 | 20-23 | 20-22 |

B.D(g/cm³)Min | 2.05-2.10 | 2.10-2.2 | 2.25-2.35 | 2.40-2.50 |

Cold crushing strength Mpa | 22 | 25 | 45 | 50 |

Production & Quality

1.Production Process

Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packing shipment

2.Quality Control

a.According to the chemical content,raw materials are classified into different levels to ensure quality of brick first.

b.During the production,every brick will be weighed twice strictly to reduce the error of weight .

c.Before delivery, the inspectors will inspect the size,appearance,physical and chemical properties of brick again in factory.

F&A

Q1.Are you a manufacture or trader?

A:To be honest we are a trader,but we have stable cooperation factories.And we can supply good pre-sale service, after-sales service.

Q2.Can we visit your company?

A:Sure,welcome at any time,seeing is believing.

Q3. Do you provide samples?

Yes, samples are available.

Q4. Do you accept OEM?

Yes, we can do OEM.

Q5.What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q6.What are the payment terms?

Usually T/T,but L/C,Western Union etc are available for us.

Q7. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

Q8.How are your products’ quality?

The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q9.How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q10.What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q11.How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

- Q: What are the specific raw materials for plastic pallets?

- There are two kinds of raw materials for plastic pallets: one is polypropylene (PP) and the other is polyethylene (HDPE).Plastic pallets for logistics storage: pp+pe material, recycled material 10%;Plastic trays for food trays: food grade PP, PE, pc;Polyethylene (HDPE) has excellent impact resistance and cold resistance, and it can resist environmental stress cracking. Excellent chemical stability, good oil resistance. Water absorption and tiny, low permeability, organic vapor transmission rate is larger. Electrical insulation is good, in all frequency range, dielectric properties are extremely excellent.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- RT3 series trolley type resistance furnace is a national standard energy-saving cycle type operation furnace. It has super energy-saving structure, adopts fiber structure and saves electricity 30%. Exclusive production of composite high aluminum nails group, car anti-collision sealing brick, automatic sealing trolley and furnace door, integrated rail, without the basic installation, placed on the ground floor can be used. Mainly used for high chromium, high manganese steel castings, ductile iron, roller, steel ball, 45 steel, stainless steel quenching, annealing, aging, and various mechanical parts heat treatment. Features: 1, no noise, no environmental pollution. 2, small heat storage, less heat loss. 3, high temperature control accuracy, furnace temperature uniformity. 4, a high degree of automation, simple. 5, PID programming can be used to set, fully automatic operation. 6, good sealing, long life, safe and reliable. Widely used in chemical, petroleum, food, metallurgy, machinery, light industry, electricity, ships, paper, mining, medicine, central heating and other industrial sectors. With the development of social productive forces, its application in various industries is more and more widespread. Two, pitannealingfurnace (for example: flange heat treatment furnace) use: the furnace for metal parts, such as ring of equipment heat treatment at rated temperature: the furnace is composed of furnace body and a movable furnace cover and control system.

- Q: Density of high alumina bricks

- Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: What is the density of a super high alumina brick and what is the price?

- Super high alumina brick, alumina content of 80% bricks, bulk density of 2.7g/cm3 or more, the factory price of about 1900 yuan

- Q: How to make refractory bricks and boiler wall adhesion more firm?

- Suggest that you use fire brick to increase the length of brick or pull the amount of turn, and use high temperature mortar masonry

- Q: What are the characteristics of high alumina bricks?

- High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining. High R.U.L, low creep high alumina brick with high grade bauxite, fused corundum, fused mullite as main raw material of high-grade refractory materials.

- Q: The difference between light high alumina brick and heavy aluminum brick

- Lightweight high alumina brick, also called high alumina insulation brick. Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. Volume density 0.4 - 1.35g/cm3. Porosity 66% - 73%, compressive strength 1 - 8MPa. Better thermal shock resistance. Usually, a high alumina clinker is added with a small amount of clay. After grinding, it is poured and shaped in the form of slurry by gas generation or foam method, and it is fired at 1300 - 1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: How are the grades of high alumina bricks differentiated?

- High alumina brick: aluminium silicate refractory product with a content of three Al2O3 (two) and more than 48%

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- The gas will directly lead the dome combustion, in order to ensure good mixing, complete combustion of gas and air in a short time, the combustion capacity of short flame or flameless combustion burner, commonly used for semi jet short flame burner.

- Q: What are the categories of bricks?

- Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

Send your message to us

High Alumina Kiln Furnace Refractory Fire Clay Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords